As we all know, more spark advance results in more power, until the point where the fuel starts pre-detonating (pinging). So the key in create a performance spark curve is more advance. This includes more initial advance, more vacuum advance and earlier centrifugal advance. In no case should the optimum total advance for full-throttle high RPM use be exceeded. This varies by engine type and cylinder head design. Since the total advance is a given, if you dial in more initial advance, you need less centrifugal advance to reach the total.

Contents |

Emission Control

To reduce certain types of emissions, many Datsun engines introduce transmission gear-selected spark advance cut-out (TCVAS). This is not good for performance, so generally only works in top gear after the car has already accelerated up to speed.

Each year, and in each region, different advance parts (both mechanical and vacuum advance) were fitted to juggle emissions of one type vs another.

Initial Timing

Most engines run OK on 5 to 10 degrees initial (base or static) timing. which is not enough far enough advanced to cause starting problems, and will still deliver decent power at the low idling speed.

Datsun 1200 distributors are designed for 7 degrees initial timing.

Because this initial figure is factored into the distributor advance curves, do not advance it further at risk of exceeding the maximum advance at high RPM.

The distributors for emission controlled A12s are designed for 5 degrees base timing. These distributors have more mechanical advance to make up for the lesser base timing, so you get the same Total advance at high RPM.

Total Timing

The total advance timing is the base timing + the mechanical timing. This tops out at 28-32 degrees at between 4200-4800 RPM. 32° is a safe amount of timing for the A12 at full throttle, and won't damage the engine. But if you exceed this it *may* (or may not) cause overheating and/or predetonation which can break the pistons.

Vacuum advance only works when there is high vacuum, so it does nothing at full throttle. It is not considered in the "total" timing, but adds more timing (and thus more power) at part-throttle conditions.

Total Advance Comparison

Total advance is the initial + centrifugal at full throttle. Because it is full-throttle, the vacuum advance is zero.

A12 typical 32 A14 typical 36

1969 KB10 A10 8° + 1971 B110 A12 PT 12° + 1970 B110 A12 CAN 7° + 12.5x2 = 32° total 1973 B110 A12 USA 5° + 13.5x2 = 32° total 1977 B210 A14 USA 10° + 14°x2 = 38° total * possibly the larger bore can take more advance? 1982 CAN A12A 12° + 10°x2 = 32° total D4A80-02 1982 CAN A14 7° + 11.5x2 = 30° total * emission-control limited 1982 CAN A15 12° + 12x2 = 36° total 1982 USA A12A 9° + 11.5x2 = 32° total D4K81-01 1982 USA A14 7° + 11.5x2 = 30° total 1982 USA A15 7° + 11.5x2 = 30° total 1974 620 L18 USA 34° total * different combustion characteristics than A-series

NOTE: The distributor curves are listed in each Datsun Factory Service Manual. Some show a graph, others have the curve specs in the text (without illustration).

NOTE: As implemented in many Datsun distributors, "curve" is a misnomer. The mechanical advance varies practically in a straight line through the RPM range.

Advance Characteristics

For a factory stock Datsun 1200, including 1.5" exhaust, curves in graphical chart form are presented below.

NOTE: The charts show distributor angle in degrees. Multiply by two to get degrees at the crankshaft pulley.

All A-series distributors have similar curves, but vary a little by year and model. Check your Factory Service Manual for your specific model and year to find the curve for your distributor. NOTE: on the side of the distributor is the model number. Mine is D412-63.

Mechanical Advance

Mechanical or centrifugal advance is varied solely by the RPM of the engine. Gasoline engines need a little advance when idling (typically 7 degrees) but a lot at higher RPMs (typically around 35 degrees, but depends on the cylinder head design and size of bore). This is called advance because the spark occurs before the piston approaches the top of the cylinder and the power stroke begins. This is called Before Top Dead Center (BTDC). The advance allows time for the combustion to get going to power the piston down with maximum force.

For the A12, you want a full 32° advance at high RPM. The stock distributors have a mechanical advance tolerance of +- 2 degrees at the crankshaft. That's a huge difference and is the reason why blueprinting your distributor -- even on a stock engine -- is important.

NOTE: If your distributor is on the low side of the tolerance it can be 4 degrees retarded and still be in specification!

Measuring Total Advance

Total advance can be verified with an advance-type Timing Light, or with a standard timing light and additional marks on the crank pulley showing where 32° is.

NOTE: all mechanical advance measurement should be done with the vacuum advance hose disconnected and plugged.

- With a standard 138 mm crankshaft pulley, make a new mark exactly 39mm anti-clockwise from the stock TDC mark. You may use crayon or grinder to mark it. This distance is 32 x 1/360 the circumference of the pulley.

- Connect your timing light and start the engine

- Verify the Dwell and Intial timing is correct. See Timing

- Once the initial timing is confirmed, rev the engine to 4800 RPM and verify the new mark is matching with the TDC indicator.

If the full timing is not achieved at high RPM, you can:

- (better) can add more initial timing to get to the 32 mark

- (best) recurve the distributor on a recurving machine

If the full timing is exceeded, retard the base timing enough to compensate.

Standard A12

These are for engines that are not EXHAUST emission-controlled, such as JDM A12s. The engine may have other types of emissions controls such as EVAPO (fuel vapor controls) or CRANK, but those do not affect spark timing.

The factory advance is a nice performance curve for stock engines. But due to factory tolerances could be several degrees too low for best performance and economy. Blueprint your distributor to ensure it is right.

Total advance is:

7° initial + 21° (10.5 x 2) mechanical = 28° total to 7° initial + 25° (12.5 x 2) mechanical = 32° total

You want it blueprinted to the latter.

1970 Centrifugal Advance - part D411-61

0° at ~550 rpm

11.5° +-1 degree at 2400 distributor rpm

Mechanical advance is all in by 2400 distributor RPM = 4800 crankshaft RPM.

EXHAUST A12

These are for EXHAUST emission-controlled engines, such as USA-specification A12, later JDM 1200s, and possibly later Australia 1200 utes. The spark advance curves are changed to reduce exhaust emissions (unburned HC, carbon monoxide, etc).

EXHAUST controlled A12 engines have lesser initial timing advance (5° compared to 7°) to reduce idle emissions. Because of this these distributors have additional mechanical advance to give you the full total timing.

Total advance is:

5° initial + 23° (11.5 x 2) mechanical = 28° total to 5° initial + 27° (13.5 x 2) mechanical = 32° total

1970 Centrifugal Advance - part D412-63

0° at ~550 rpm

12.5°+- 1° at 2,100 distributor rpm

Mechanical (Centrifugal) advance is all in by 2100 distributor RPM = 4200 crankshaft RPM.

1973 Centrifugal Advance - part D412-80 for manual transmission

0° at ~600 rpm

12.5° +- 1° at 2,125 +- 25 distributor rpm

Mechanical (Centrifugal) advance is all in by 2150 distributor RPM = 4300 crankshaft RPM.

1973 Centrifugal Advance - part D412-89 for AUTOMATIC transmission

0° at ~600 rpm

12.5° +- 1° at 2,325 +- 25 distributor rpm

Mechanical (Centrifugal) advance is all in by 2350 distributor RPM = 4700 crankshaft RPM.

Changing Mechanical Advance

The distributor shop can change the mechanical advance by varying the fly-out weights and the springs in the distributor, and by modifying the slots and pins that limit the weight movement.

It appears Datsun varied only the Springs and the Slots (Cam Assembly/Rotor Shaft Assy). All A12A/A14/A15 used the same weight set at least in North America.

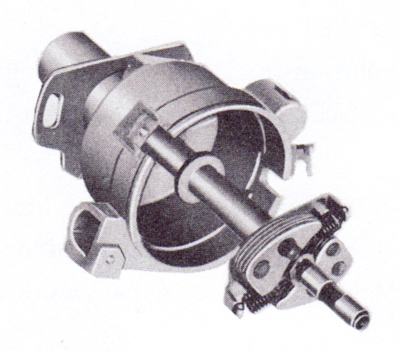

Mechanical Advance Governor, showing fly-out weights, springs, and weight pins (which fit into the slots in the advance plate)

They can balance initial, total, starting RPM and ending RPM against each other. Simply rotating the distributor only shifts inital and total so is not optimal.

RPM LIMITS

heavier Weights: advance occurs at lower RPM lighter Weights: advance occurs at higher RPM heavier Springs: advance occurs at higher RPM lighter Springs: advance occurs at lower RPM * Could possible bend the spring anchor tabs * for adjustment

Changing just one spring or weight can put a "curve" in the advance, that is, faster advance in the lower RPMs and slower in the higher RPMs (or vice-versa).

RANGE of RPM

longer Slots: increase both starting and ending RPMs shorrer Slots: reduces both starting and ending RPMs * Slots can be modified on one side to change only * the beginning or ending RPM The Hitachi slots and/or pins appear to be assymetrical

smaller diameter Pins: more RPM range larger diameter Pins: less RPM range * side of pin facing the slot can be ground down * or be built-up. Pin width should match slot * width for the most part, so don't grind the pin * all around.

Slotted advance plate. Nissan incorporates this part into the Cam Set/Rotor Set.

The beginning RPM should be set to a little above idle speed, so that it is inactive at idle. Otherwise you will get a hunting idle as the weights swing a little.

If you change the total amount of advance, you need to reset the base timing to compensate, or vice-versa.

All these considerations are why a distributor shop are recommended.

Parts, Type D40

Original Datsun 1200 Hitachi Type distributor mechanical advance parts. Type D40 & D41 Hitachi distributors were used until about 1975 by most Datsun engine families.

COMMON PARTS 22109-71300 WEIGHT-governor (2) ALL, including L-series * 173 = PL411-UTK 22108-H2301 ASS'Y-SHAFT A-series Engine [replaced all earlier]

22100-H1001 ASSY-DISTRIBUTOR (HITACHI D411-61) B110 (except GX) 22110-H1000 SET-SPRING, governor * also used by L14S 1971-1972 510 (Hitachi D411-63) 22132-21005 ASS'Y-cam * 210 = 510S (1967) * superceded by 22132-22005 * 220 = P510TK 1600 SSS

22100-H2300 ASSY-DISTRIBUTOR (HITACHI D407-54) (High Gas) GX * 146 = SP311 Datsun Roadster with R16 (Hitachi 22100-14600) * SP311 and 411 SSS both use 22100-14600 22110-14600 SET-SPRING, governor 22132-14605 ASS'Y-cam

22100-18006 ASSY-DISTRIBUTOR (HITACHI D412-53K) (Reg Gas) GX * also B10 (ex. coupe) 22100-H5700 DISTRIBUTOR-ASSY (HITACHI D412-91) 1973-1975 B210 A12T 22110-18001 SET-SPRING, governor 22132-18005 ASS'Y-cam

22100-25706 ASS'Y-DISTRIBUTOR (D412-57K) B10 Coupe * 8 BTDC 22110-25700 SET-SPRING, governor 22132-25705 ASS'Y-cam

22100-H5000 DISTRIBUTOR-ASSY (HITACHI D411-89) 1973-1974 B210 A12S 22100-G1600 DISTRIBUTOR-ASSY (HITACHI D411-A3) 1975-1977 B210 A12S.V 22110-H1000 SET-SPRING, governor 22132-18005 ASS'Y-cam

Parts, D4A Type

Comparison for the D4A/D4F/D4K large-cap hitachi distributors.

22109-A5500 WEIGHT SET, GOVERNOR [all engines] 22110 SPRING SET, GOVERNOR 22132 CAM ASSY/ROTOR SET [incorporates the slots] 22108 SHAFT ASSY [incorporates pins and spring anchors]

D4A80-02 1982 CAN A12A 12° initial + 10° mechanical Spring set: 22110-H7601 Weight set: 22109-A5500 Cam ass'y: 22132-H7601

NA B310 A14/A15 Spring set 22110-H9100 FED 22110-H9160 CAL 22110-H9300 CAN Cam ass'y: 22132-H9100 FED 22132-H9160 CAL 22132-H9300 CAN NA B210 1978 FED AUTO springs: 22110-H7301 cam/rotor: 22132-H7300 shaft: 22108-H7300

1975 CAL MT springs: 22110-H7301 or 22110-H7300 cam/rotor: 22132-H7300 shaft: 22108-H7300

1974-1976 FED MT springs: 1974 22110-H7200 1975- 22110-M5601 cam/rotor: 22132-M5600 shaft: 22108-M5600

Vacuum Advance

1973 Vacuum Advance - part D412-80 for manual transmission

- 0° at 6 inHg (inches of mercury)

- 6.5° at 9.5 inHg

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)