Contents |

Oil Check

The oil should be checked every 3000 miles or 3 months, or whenever carburetor operation seems incorrect. Nissan recommends:

- 20W engine oil

- 10W-30 engine oil

Remove the oil cap Nut and check the oil level. Do not add oil if it is between the two lines:

The damper only holds 3cc of oil, so be careful when adding. Just a touch is all that is called for.

Idle Mixture

Choke Cable Adjustment

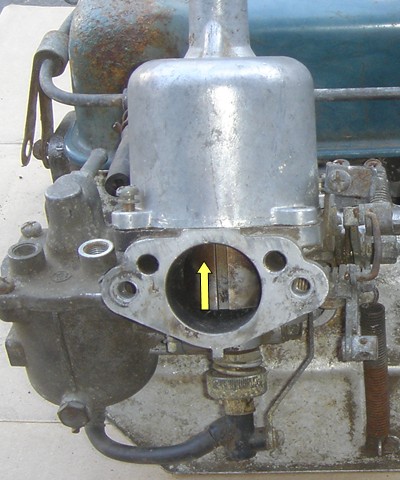

Adjust the fast idle or "starter interlock", so that when the choke is engaged, it forces the throttle plate open slightly.

- Squeeze the choke lever as shown (nozzle will move down). The yellow connecting link will force the throttle open slightly.

- Measure the throttle plate opening

- 0.6 mm

- Adjust the amount of opening by bending the link.

Throttle opens by 0.6 mm (measured between edge of plate and throttle bore)

Float Level Verification Check

To check the float level, attach a sight glass to the drain plug.

- Remove drain plug. Catch gasoline in a cup.

- Take a 5/16" hose L-fitting. Fit clear 30mm plastic tubing pointing up, and jam the fitting into the drain hole. Make sure it is secure. Position it parallel to the bowl (straight up/down).

- Nissan had a tool for this, number ST19200000 "Float level gauge"

- Start the engine and let it idle.

- Measure the level of fuel in the tube

- 22-24 mm from fuel bowl gasket

- Adjust float if too high or too low

Float Level Static Adjustment

When replacing the float level needle and seat, set the static level of the float.

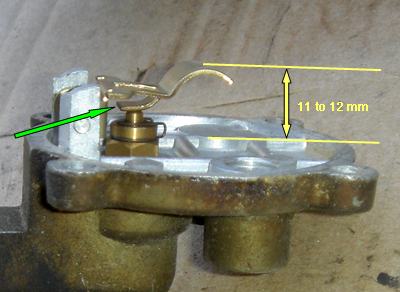

- Remove Float Chamber cover

- Place it upside down and level

- Level from top of brass lever to flange (without gasket) should be:

- 11-12 mm

- If needed, adjust lever by carefully (and slightly) bending inner tab of brass lever.

Piston Lift Check

Check the piston left every 3000 mile or 3 months, or whenever carburetor operation is unsatisfactory. Grit may cause the piston to stick, affecting performance.

- Remove air cleaner

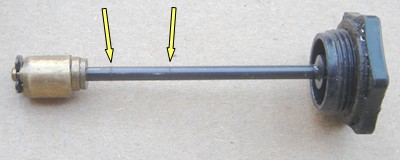

- Remove oil cap nut

- Stick your finger in the bore. Slowly lift the piston to avoid splashing the oil.

- Lift piston about 8mm until it stops

- Drop piston. It should click against the venturi stop.

- Replace oil cap nut.

- Lift piston again this time against resistance of the oil. Piston should drop freely.

- If movement is sticky other otherwise not smooth, remove Suction chamber and carefully clean chamber and piston.

Cleaning Suction Chamber

Remove the four bolts of the Dome Top (suction chamber).

The piston holds the oil, so keep upright.

CAUTION: Do not knock piston or jet. This is a precision assembly and a little jar can damage it.

CAUTION: Do not sand. It is a precision fit.

- Clean with solvent (ether or carb cleaner)

- Air dry to prevent dust or lint particles from sticking to surface

- DO NOT oil inside of chamber nor edge of piston. It must be clean and dry for proper operation

- Lightly oil the piston tube (a couple of drop)

- Reinstall. If you turned the piston upside down, don't forget the nylon packing (washer).

- Replace oil if you drained it from the piston tube

NOTE: There is no gasket between the Suction Chamber and the Throttle chamber.

Changing Needle Jet

Datsun 1200 GX engine uses needle M-75. Normally there is no reason to remove the needle jet. It can be thoroughly cleaned without removing.

If you wish to change the needle or replace a damaged needle:

- remove screws holding Suction Housing and lift housing off

- lift piston up of the throttle body

- drain piston tube of oil

- remove set screw from side of piston

- carefully grab base of needle a ease out of piston.

- If it won't come out, use needle nose pliers at base of needle. Do not scar, scratch or bend the needle.

- when fitting new needle, be sure base of needle is flush with bottom of piston (not with the boss).

CRITICAL: All range of performance and economy rely of needle base being flush with piston face. It will go in further, but must not be allowed to. Use a straightedge to confirm.

The set screw looks like a traditional Hitachi downdraft jet screw, but has no hole in it. Just tighten slightly to fix the needle.

Nozzle Cleaning

The nozzle is a precision assembly located on the bottom of the carburetor.

Do not disassemble unless required. General cleaning can be done as follows:

- Remove fuel line at either end (at the nozzle or at the bottom of the float chamber).

- Let drain

- lift piston with finger

- spray carb cleaner (or ether) up the fuel hose into the nozzle. Spray should come out the venturi

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)