| Revision as of 23:01, 14 July 2018 ddgonzal (Talk | contribs) (->Boost pressure) <- Previous diff |

Revision as of 23:09, 14 July 2018 ddgonzal (Talk | contribs) (->Boost pressure) Next diff -> |

||

| Line 249: | Line 249: | ||

| But don't let the engine ping (detonatation):<blockquote>[{{Post|221128}} steveo]: in a standard bottom end ... [with] a crappy tuning it leaned out up high and pinged like crazy at that amount of boost ... I had trouble with 'rolling' the ring lands above 15psi</blockquote> | But don't let the engine ping (detonatation):<blockquote>[{{Post|221128}} steveo]: in a standard bottom end ... [with] a crappy tuning it leaned out up high and pinged like crazy at that amount of boost ... I had trouble with 'rolling' the ring lands above 15psi</blockquote> | ||

| + | |||

| + | Everything about having an engine survive under boost is the "tuning" (control over the fuel burn) | ||

| + | * wastegate - no spikes. An external gate may work better | ||

| + | * injection - complete fuel control is easier to achieve than with carburetion | ||

| + | * ignition - complete spark control (no detonation/pinging) | ||

| + | * Large enough plenum and single throttle body for volume airflow | ||

| + | * exactly perfect AFR (air/fuel ratio) for complete even burning. Under full boost this means an unusually rich ratio to keep the charge cool and avoid detonation. Note that stoich ratio (14.7) is not ideal for either power nor fuel economy but is used only to enable [[Emission_Controls#Catalytic_Convertor|catalytic conversion]] | ||

| = Induction and Exhaust = | = Induction and Exhaust = | ||

Revision as of 23:09, 14 July 2018

Forced induction comes in two forms: Supercharging and Turbo-supercharging. This article will focus on the turbocharger. For a comparison with the supercharger, see Forced Induction.

For the turbo compressor itself, see Turbos

Overview

For specific turbocharger models, see Turbos

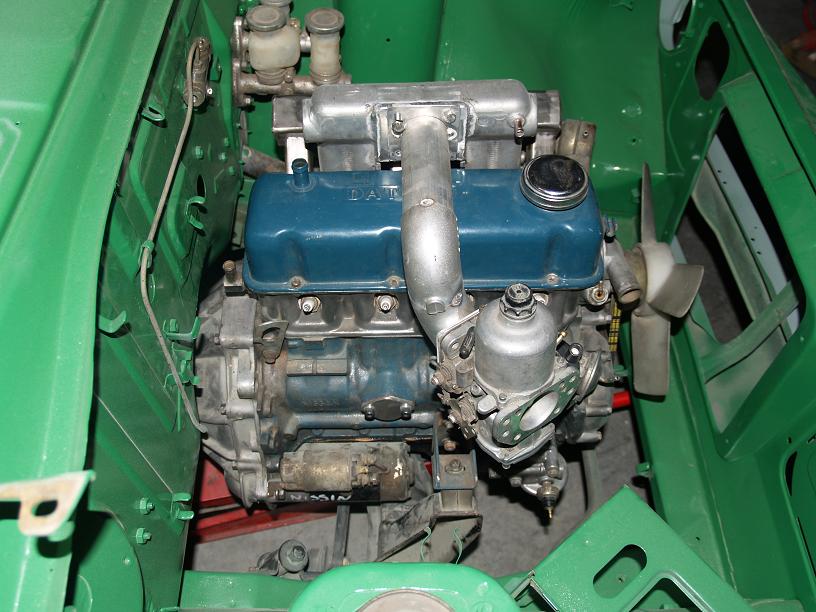

Big Power from a stock A-series engines can be had by adding a turbocharger. A turbo setup on an A12 makes more power and torque than a worked non-turbo A14, for a fraction of the build cost.

See Main Article: $1200 EFI Turbo A12

Turbo setups range from modest to wild.

Discussion: POST regarding Turbocharging A12

Stage 1

20% more HP than stock.

A stock A-series engine can take 10 psi. You don't even need an intercoolor, and so you can use draw-through on a stock carburetor. But blow-through is easier.

- Stock engine

- Loop piping from stock exhaust manifold

- Small Wrecking yard turbo ($100). If sized small enough, no wastgate or blow-off valve is needed

- Tee into the oil pressure line, feed it into turbo. Tap a return line into the oil pan

- Piping from turbo to stock carburetor via a top hat

- Set initial timing at 3 degrees

- In the distributor, weld the advance slots partially to limit mechanical advance

- Keep the stock vacuum advance (it will have no effect under boost)

- Fit larger power valve to carburetor

- Fit secondary main jet two sizes larger

- Stock fuel piping with medium pressure fuel pump (above 10 psi)

Limit boost to 5 psi.

Or go to 10 psi for short bursts on cooler days.

Stage 2

10 psi. 40% more HP.

- stock block and head

- Fit Intercooler (precludes use of draw-through)

- Box the carburetor to go higher than 10 psi

- Rejet primary main two sizes larger. Secondary main 3 sizes larger. Power valve increase.

- Retard timing to 0 degrees. Connect vacuum advance up directly to manifold. This will help idle and starting out under low throttle, but the vacuum advance will have no effect under boost

- Use 75.5-degree thermostat

- High volume/high pressure fuel pump

- anti-surge tank up front

- Use custom exhaust manifold to mount the turbo

- 2" exhaust

- H165 rear axle

Stage 3

100% more HP than stock. Requires modified engine, but not high-RPM usage.

2 bar (28.2 psi)

1 bar (14.7 psi)

Do all the stage 2 modifications plus:

- Use new Nissan rod bolts, torque to spec

- Use ARP head studs

- Fit Intercooler (precludes use of draw-through)

- Custom pistons for low compression (7:1)

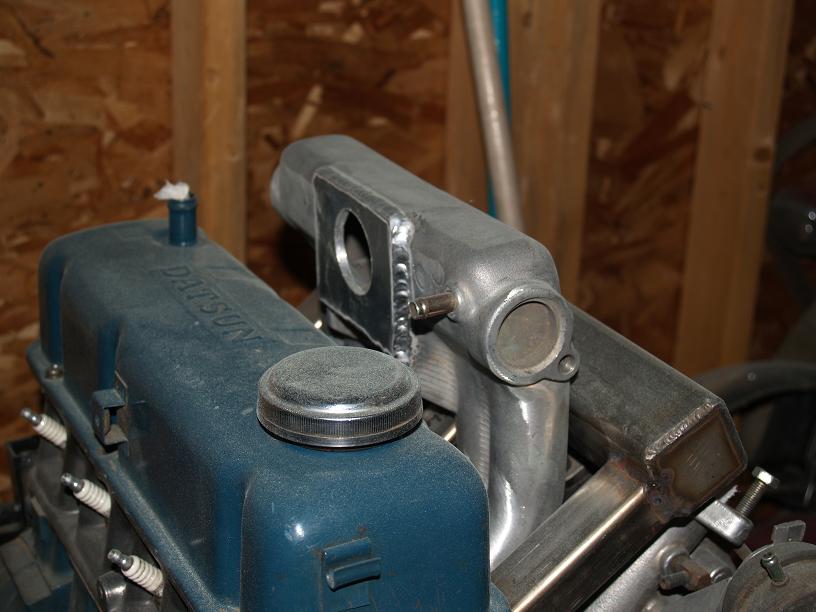

- A12GX head, ported

- Copper head gasket

- Oil Cooler

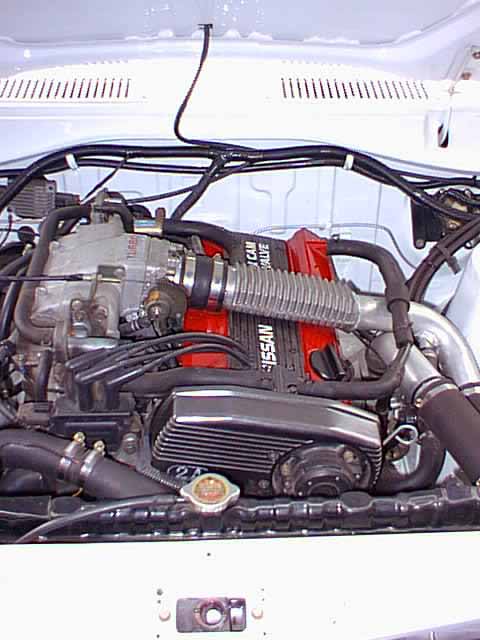

- EFI (or professionally modified & tuned box carburetor)

- custom inlet manifold with large runners

- 2.5" exhaust

- Carefully-sized ball bearing turbo

- 5/16" fuel lines and high volume/high pressure fuel pump

- Fuel tank modified with baffles, or anti-surge tank up front

- Custom-recurved distributor with Electronic Ignition

- Spark retard system

- Water-injection system

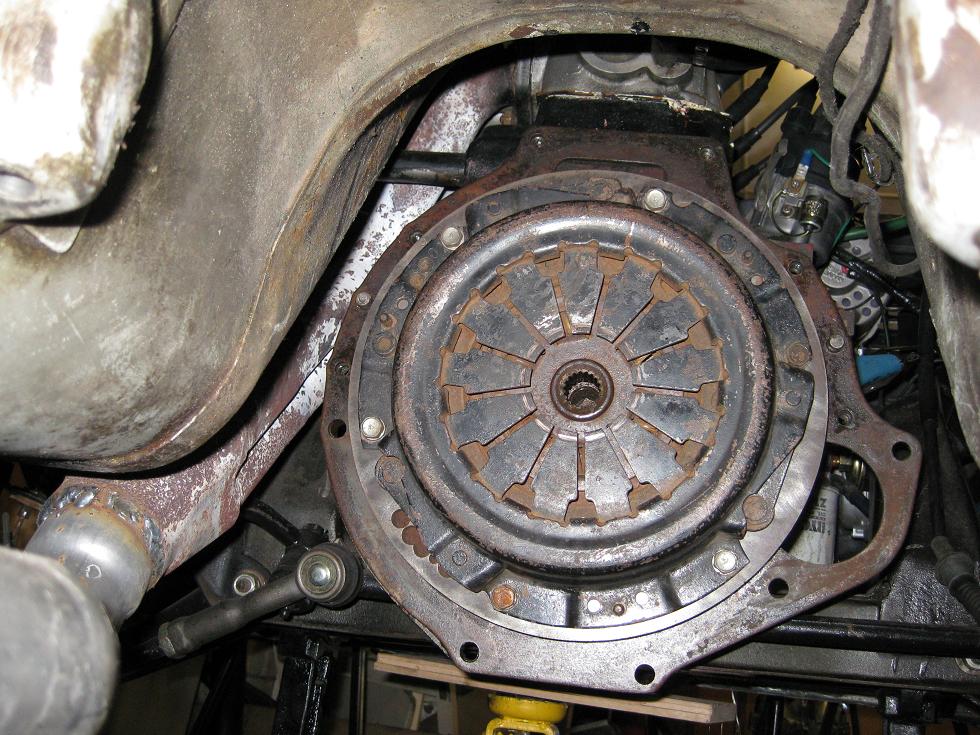

- 63-Series Transmission for A-series

- Heavy duty clutch

- H190 rear axle (or H165 rear axle with heavy-spline axles)

- traction bars

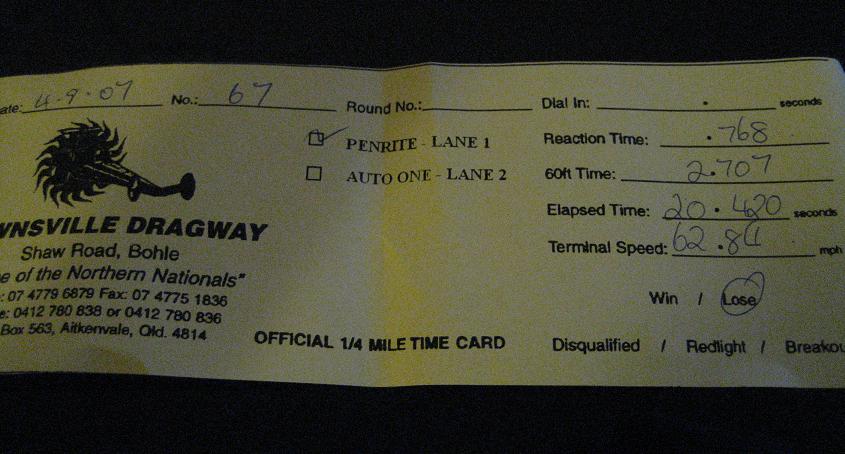

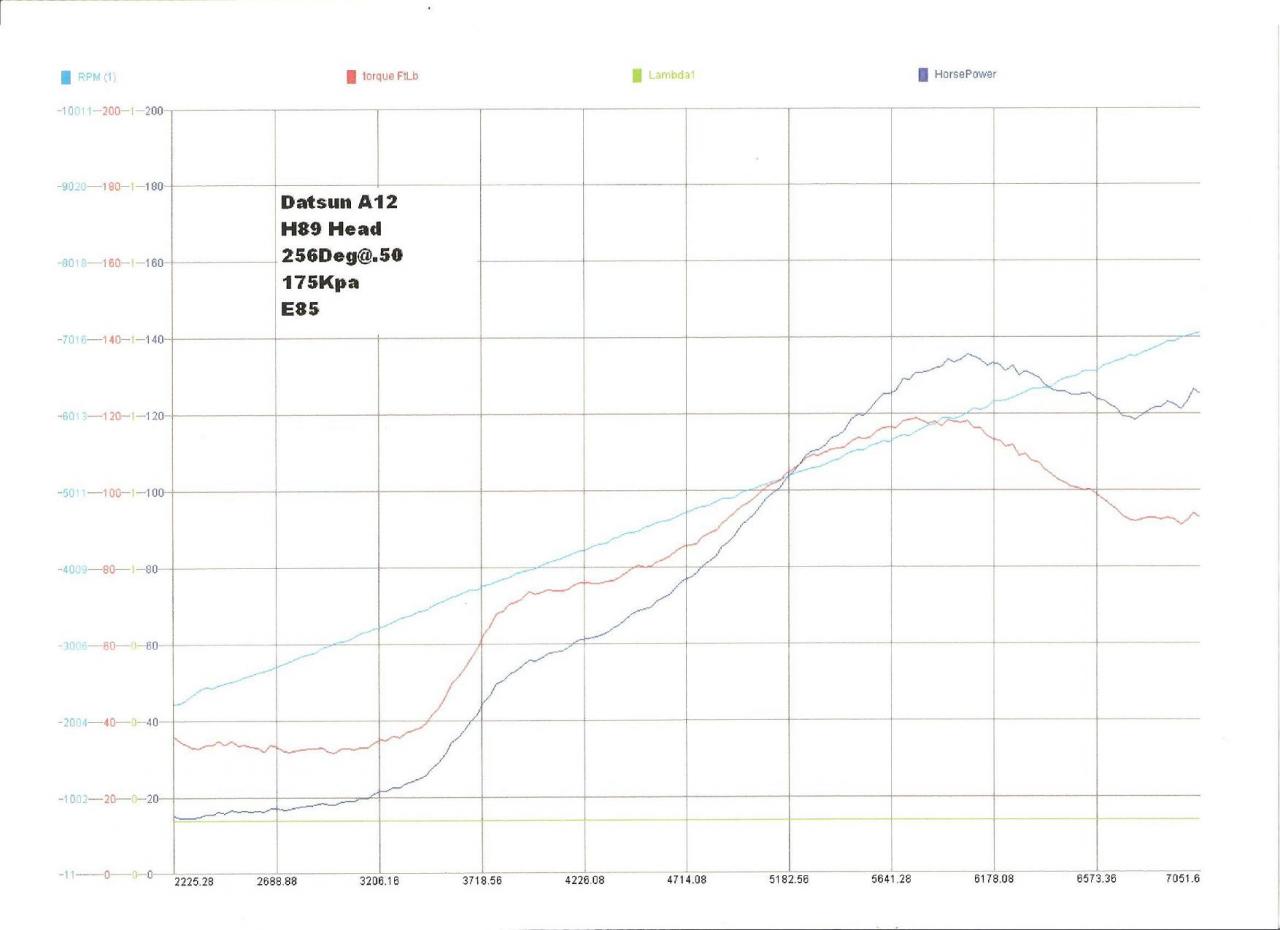

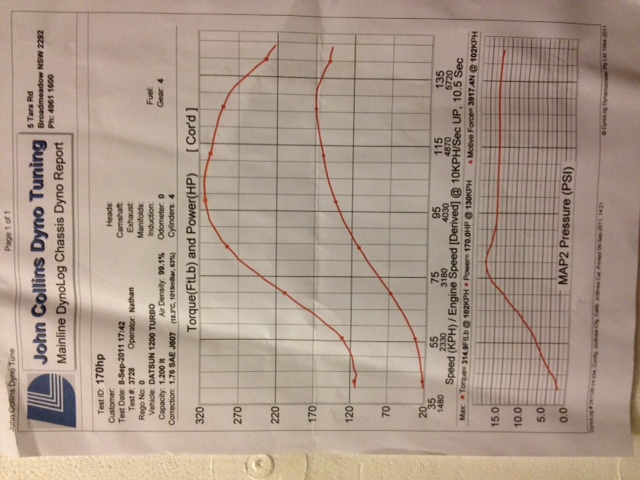

Proof

A15ETT

See main article: A15ETT

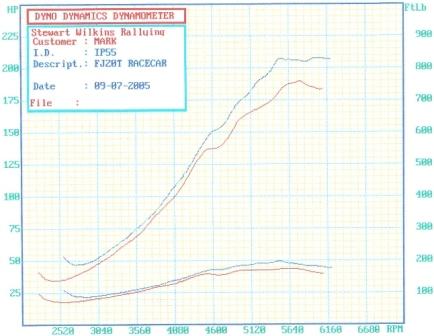

Twin-turbo A15 by 1200rallycar

A15 Before: 52.3 kw (70.1 hp)

A15 After: 75.6 kw (101.4 hp)

Sikyne's A12

See: POST A12 Turbo Development thread

160+ rwhp @ 15 lbs boost (standard H89 Head) 240+ rwhp @ 24 lbs boost (big valve ported head) 2nd-hand GT2860R (707160-5) ball bearing turbo E85 fuel, intercooled stock and unmodified H89 head Cam: 236 Degrees at .050 lift Maximum advance at 16 psi boost: 23 degrees ARP head studs stock pistons, crank and rods standard headgasket about 120 Lb Ft from 5100 to 6800 RPM @ 15 psi

Draw-through or blow-through turbo systems?

Section by datto_dave

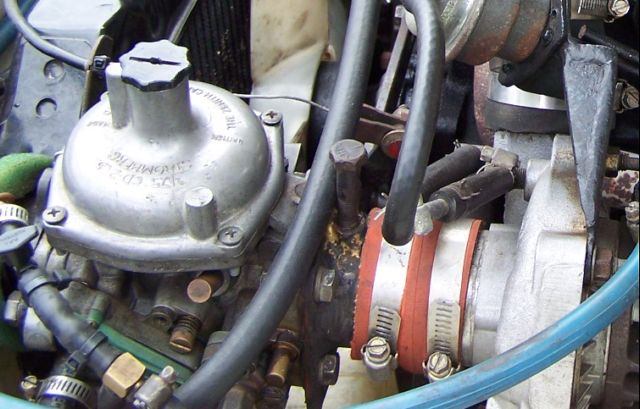

The carburettor can be mounted in two positions on a turbo-charged engine, and a great deal of controversy exists as to which is better. The carburettor can be mounted such that it feeds air into the turbo then the turbo feeds it to the engine. This is known as a Draw-Through system. Under these conditions the carburettor operates more or less as it would on a naturally asperated engine. Another school of thought says that the carburettor should be mounted between the turbocharger and the intake manifold. This means that the turbocharger draws fresh air and pumps it into the carburettor, which then feeds the fuel/air mixture to the engine. This blow-through setup allows the use of an intercooler, which draw-through does not. In fact there are several advantages to a blow through over a draw through, because the fuel/air does not have to travel through the turbo. The blow through system requires a boost sensitive rising rate fuel pressure regulator in order to increase fuel pressure with boost pressure as the rpms rise.

Blow-through system feeding Boxed carburetor

Another snag to the blow-through system is that the carburettor must be enclosed in a pressure box and the fuel supplied to the carburettor must be at a suitable pressure above the boost pressure. This means the fuel pressure has to be regulated in accordance with the boost pressure at all times. My own personal preference to date has been for the draw-through system this is largely substantiated by other people in the industry who are running very high-powered turbocharged cars. Almost all are using draw-through systems. However, the speed equipment industry doesn’t stand still. A new development with blow through systems could change the picture. The specially designed for ‘blow-through turbo applications Dellorto side draught carburettors may well be that development.

Blow-through system feeding carb top-hat

A third possibility exists: fuel injection. Here, the injection system has to be designed to measure the amount of air going into the turbocharger by whatever means. It then injects the correct quantity of fuel into the engine at whatever point is convenient. The butterflies for throttling the engine may be situated either prior or after the turbocharger, depending on ease of installation layout. If the injectors are situated in such a position that they injected into a high pressure boosted environment, then the injection pressure must be compensated for by whatever pressure the boost level has reached. Fortunately most fuel injection systems have ample fuel pressure to cope with as high as 40-45 psi used in alcohol burners.

Intercooler

An Intercooler is not needed. The first three years of the Porsche 911 Turbo didn't have one (75-77), yet this 3.0 liter turbo outperformed 7.5 liter NA cars. However there are very good reasons to use an intercooler, including:

- Intercooler is worth the extra cost and complexity, because it significantly reduces the temperature of the compressed air, which increases the boost possible with a given octane fuel

- An alternative is to use water or alcohol injection. Some OEM applications used water injection (ex. 1962 Oldsmobile Jetfire)

An intercooler can result in far more HP, but requires a blow-through system (boxed carburetor) or EFI port injection. This is because for safety you don't want air-fuel mixture going through the cooler, where it will condense out of the airstream and result in fuel puddles in the cooler!

By keeping the air cool and therefore dense, the same boost will make more HP, because more air is entering the engine. Because it's not overheated, more spark advance can be applied for more HP.

Can you re-purpose a car radiator and use it as an intercooler? Using an aluminum radiator should be better than nothing. Unless someone actually tested this, we are all just guessing as to whether it will work or not. Radiators can flow a lot of water, and air is easier to pump ... so air should flow through w/o significant restriction. Putting this in front of the car should allow some cooling effect, although obviously not as a much as a purpose-designed cooler.

Also see: Intercooler Photo Index

Nissan GTiR factory-style intercooler (top mount) | Traditional in-front-of-radiator intercooler

Water Injection

An alternative to an intercooler is to use water or alcohol injection. Some OEM applications used water injection, for example the 1962 Oldsmobile Jetfire injected water/alcohol mix.

Boost Cooler brand uses a 300 psi pump to inject fluid just before the throttle plate.

Into the air filter is quite effective for a suck through turbo. It not only cools the air fuel mixture but also cools the compressor wheel and that helps the ADI atomise also. But there is a problem with this system, water WILL pit the compressor wheel over time and over time wear out the turbo faster.

ADI tank can use a pump to spray liquid into the system (see discussion about eliminating the pump)

Wastegate

A Wastegate is used for adjustable control over boost pressure. When the set pressure is exceeded, exhaust is routed around the turbine to go out the tailpipe

- Not needed if you carefully size the turbo to the application (ensuring that at maximum rpm, design boost is not exceeded). Older OEM applications used this method.

Blow-off valve (or recirculation valve)

A Blow-off valve is used to preventin the turbo from surging, for example during gear shift or whenever throttle is closed. Porsche uses these, so obviously they work.

- Blow-off intake boost to atmosphere. Boost is lost. Simple, inexpensive

- Blow-off to compressor inlet (recirculate back through turbo inlet). Used to enhance throttle response: Boost is kept in circuit for immediate availability when throttle is opened again

A Blow-off valve is OPTIONAL. Many turbo setups work fine without a blowoff valve.

Carburetor Setup

- EFI is best allowing better control of mixture, but carbs can work fine

- Draw through was used by many OEM setups. It is reliable, and the simplest option. The downside is you can't use an intercooler, as the fuel will condense in the cooler.

- Need richer jets to keep air charge cool and prevent detonation

Blow Thru

Blow through works well. The main reason to use this over a draw-through is so an intercooler can be used.

See main article: Boxed carburetor

Boxed carb allows a more or less stock carb to be used, the outside pressure balancing the inside pressure

Top Hat style

Draw Thru

Suck-through setups are simpler and more fool-proof than blow-through.

Turbo kit with Stromberg carburetor (Datsun L-series engine)

Spark Curve

The more compression, the less advance the engine can handle. But a high-compression engine can still use some advance, and even a forced-induction engine needs some advance to make the most power at varying RPMs. The key is LIMITING the advance to a safe level.

Consequences of too much spark advance: cracked pistons, broken ring lands

What about locking the distributor? Yes, if you lock the advance mechanism, yes, it can help prevent detonation, but also it won't make the best power. Locked distributor will only work great at high-RPM, high-boost condition -- which is where racers spend most of their time, so it works well for racing. For a street engine, you will have a more flexible, more powerful engine at all RPMs by NOT locking the distributor, but by limiting the advance.

CONSTANT-LOAD RACING METHOD

- Lock the distributor advance. Set full timing to an appropriate level, say 30 degrees for a high-compression engine or for maximum advance at 16 psi boost: 23 degrees.

LOW-DOLLAR STREET POWER METHOD

- In the distributor, weld the advance slots partially to limit mechanical advance (see Limiting Mechanical Advance)

- Keep the stock vacuum advance (it will have no effect under heavy throttle or boost)

- Connect vacuum advance up directly to manifold. This will help idle and starting out under low throttle, but the vacuum advance will have no effect under heavier throttle

- Set initial timing to lower than normal, say 3 degrees or 0 degrees (instead of the normal 5-7)

- Downside: On a forced-induction engine, the advance won't be right for varying boost levels. You'll have to set the advance for full boost scenario, giving up HP and fuel economy for lower throttle conditions such as highway cruising

BEST METHOD: fully programmable ignition

- use a crank trigger with a fully programmable ignition system. MegaSquirt and other ECUs can provide initial timing, limited full timing, timing under boost and even retard under boost and compensate for high temperatures.

- use a standalone advance controller like the Block Box or an MSD Programmable, which allows for limited mechanical advance along with variable retard under boost, off-boost, and partial-boost conditions. With such a controller, the distributor is locked, and the box takes over the exact timing curve.

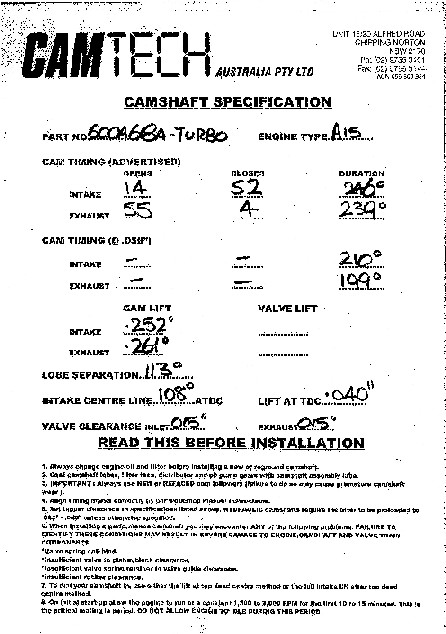

Camshaft

The stock A12 cam works well with a turbo.

If you wish to run lower revs than the standard A12 6,000 RPM shift point, a milder cam can be installed. If you want more power, a higher RPM cam can be fitted.

Your local cam grinder can advise on the best cam for your usage patterns.

Fuel pump

- Draw-through

- Stock fuel pump is good for draw-through setup. It's not enough for a blow-through setup, as 2.5 boost would overpower the fuel pressure

- Blow-through

- Using a low-pressure (15 psi) electric pump oughta be good for a 10-12 psi boost.

- Needle and seat has trouble holding more than 10 psi fuel pressure. Better to use a secondary 15-psi pump to cut in only when needed.

- Best setup is to use a rising-rate regulator with a high-psi pump. Excess fuel is returned to the tank.

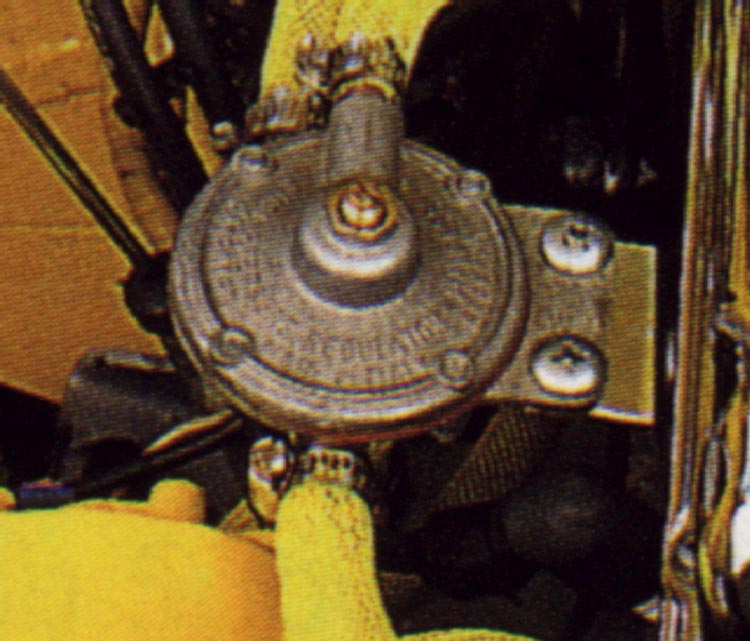

Malpassi rising-rate regulator

Turbochargers

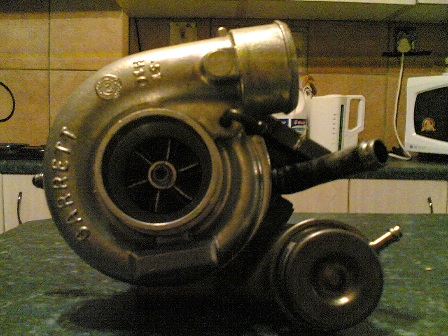

See main article: Turbos

- T3 is pretty big for an A12. Needs high rpm, head work, etc

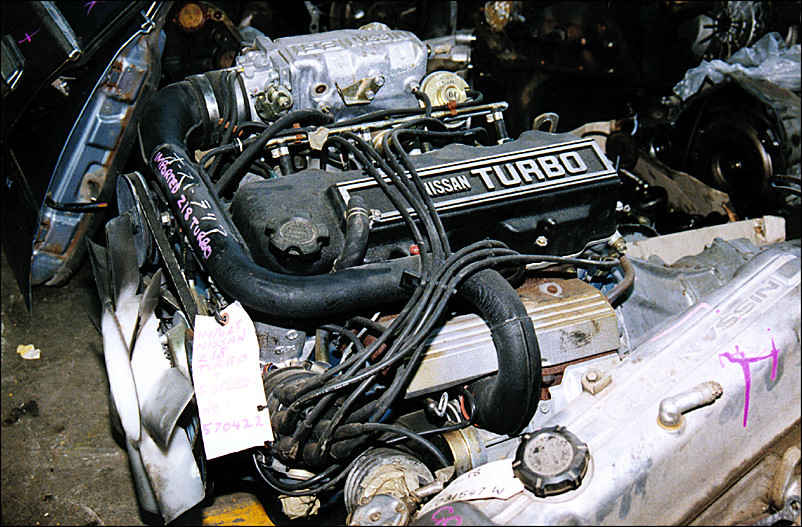

- Mid-80s Nissan Pulsar turbo (E15 engine) has integral wastegate

- go_the_datto actually tried Daihatsu diesel 1.0 turbo on A12. Good response in lower rpm ranges. Two make better twin-turbo application for A12

Here is some helpful info on everything from how a turbo works to choosing the right turbo for your engine based on compressor maps Turbo Tech

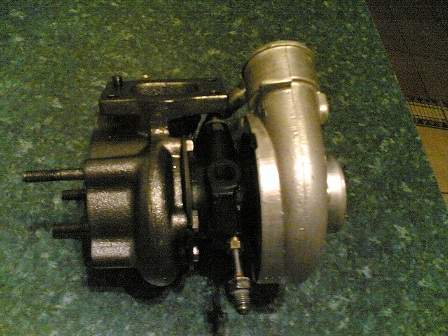

Flange

Flanges are different to suit each turbo style. For example T3 pattern requires a T3 flange some of the common types are T25/28 ,T03,T04, then there is open and split pulse.

Diesel vs. Petrol Turbos

Barpk: The main difference between a petrol and diesel turbo is its seals. Diesel turbos don't have positive seal turbo seals, which means that if put it in a suck-through system they can leak oil under extreme vacuum, which happens when throttle is closed. This is not a problem in a blow-through system.

Boost pressure

- 6-7 psi is what a lot of non-intercooled OEM applications use

- 15-17 psi is possible with a stock A12/A14

- 14.7 lbs gives theoretically double the airflow so max. power would be about 2x stock, but this isn't actually the result. The reason is that the stock induction and exhaust system won't flow this much air under pressure. However, the low rpm torque could approach 2x (at about 2250 rpm) if a small turbo is used. So a 130hp turbo engine will have much more performance than a 130hp NA engine

- 1986 Honda 1.5 liter ran boost of 4.0 bar - that's 300 bhp ... per cylinder ... with special fuel

POST frankthedolphintrainer: its been proven by a few members already that stock bottom ends can handle massive boost. i still run 15.6 psi on my daily and have had no problems

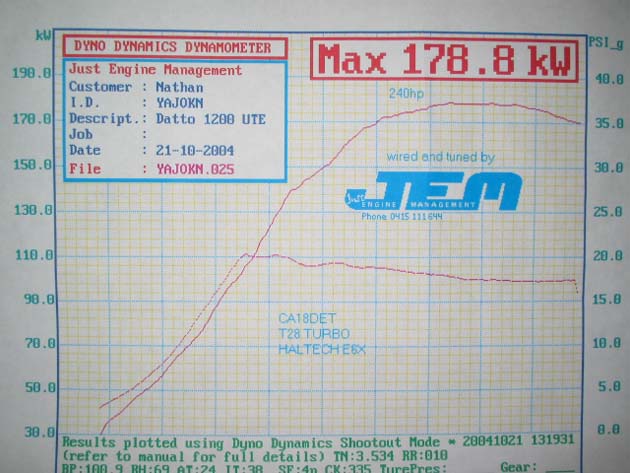

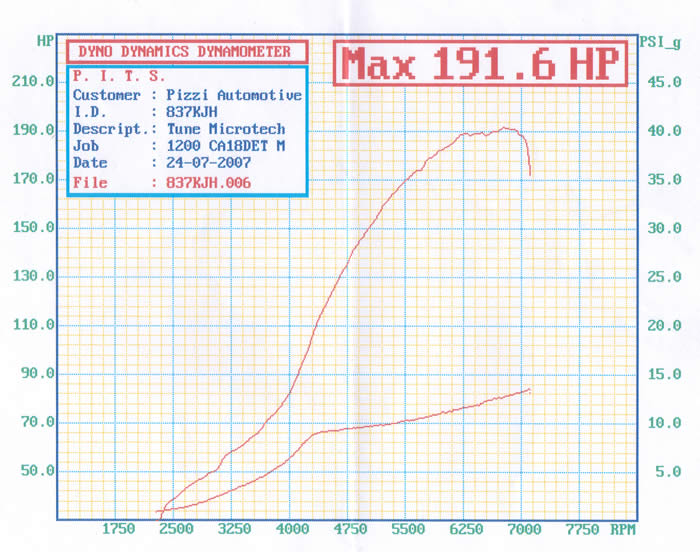

POST about Yatala 240hp A-series: rods ARE stock because he raves about there original quality and strength - he mentioned he was expecting it to throw a rod but it hasnt so he likes the standard rodsBut don't let the engine ping (detonatation):

POST steveo: in a standard bottom end ... [with] a crappy tuning it leaned out up high and pinged like crazy at that amount of boost ... I had trouble with 'rolling' the ring lands above 15psi

Everything about having an engine survive under boost is the "tuning" (control over the fuel burn)

- wastegate - no spikes. An external gate may work better

- injection - complete fuel control is easier to achieve than with carburetion

- ignition - complete spark control (no detonation/pinging)

- Large enough plenum and single throttle body for volume airflow

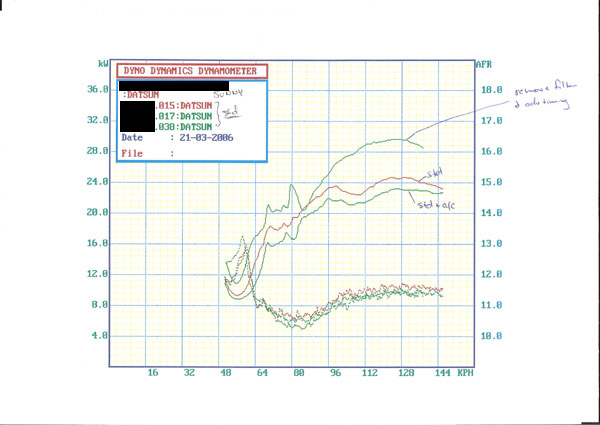

- exactly perfect AFR (air/fuel ratio) for complete even burning. Under full boost this means an unusually rich ratio to keep the charge cool and avoid detonation. Note that stoich ratio (14.7) is not ideal for either power nor fuel economy but is used only to enable catalytic conversion

Induction and Exhaust

Obviously, for more airflow, a higher flowing carb, intake, heads (ports and valves) and exhaust system is beneficial. The turbo will increase power on a stock engine, but increasing the airflow capability of the engine will bring your turbo engine to its full potential

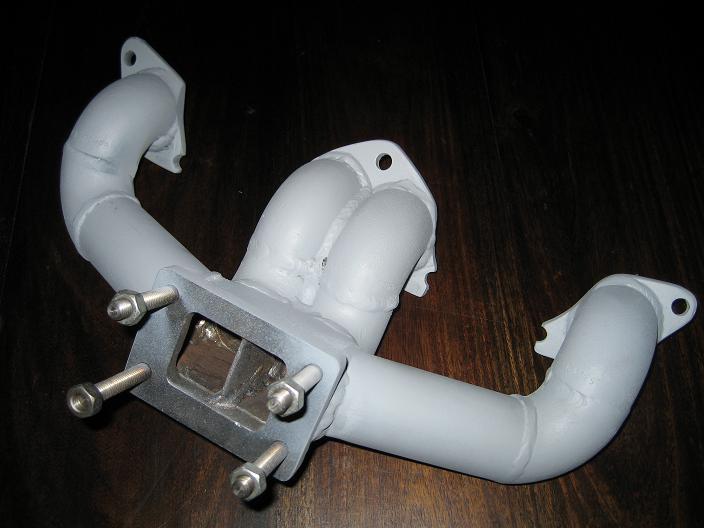

Exhaust Manifolds

The stock manifold may be used with a J-pipe for mounting a turbo. But a custom manifold that allows direct mounting is more efficient (allows more power).

Intake Manifolds

The stock inlet manifold may be used. But obviously a larger one makes for more HP.

See main article: Turbo Inlet Manifolds

Kit

Factory Turbo Systems

Might you spend less money and get more horsepower and reliability by swapping in a factory turbo motor?

Nissan Turbos

Z18T. See Z-series Engine Swap

CA18DET. See CA-Series Engine Swaps

SR20DET. See SR engine swap

Mazda Wankel Engine – Turbo

Mazda 13BT. See Mazda rotary engine swap

Mazda piston Engine – Turbo

Builds

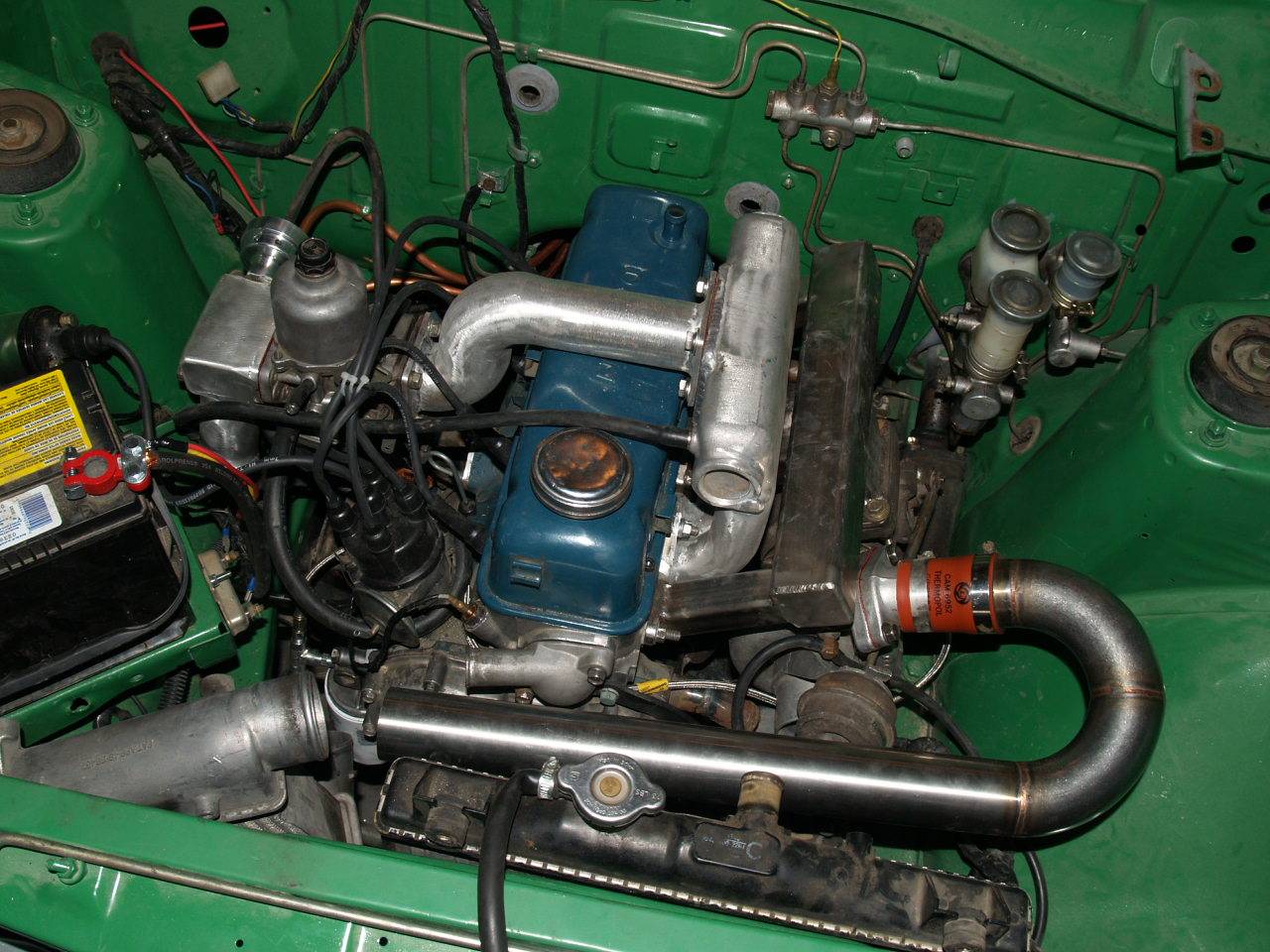

B20 A15

josh_c

Suck-through SU, the classic setup

slam1024

slam1024 added a turbo

* 1973 Datsun 1200 2-door sedan * Custom manifold with runners from Tercel * stock SU blow-through setup from 1.3 liter MG Metro Turbo

kegs

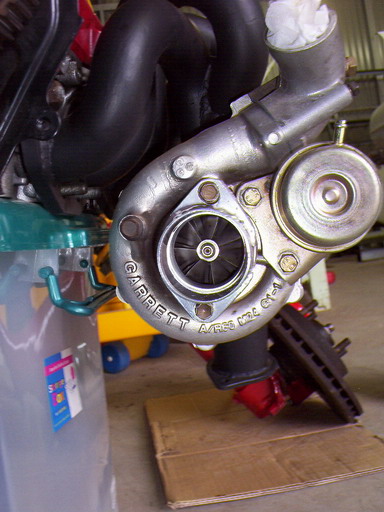

Turbocharged A15 Twin Dellorto DHLA 45 carburetors on Redline manifold Custom airbox hat Garret A/R 48 turbo Intercooler from 200SX 2.5 inch dump pipe Liverpool Exhaust

fat910

Unmodified A12 short block 8 to 10 pound boost hi flow garrett t2 custom hat and weber carb custom sump vl turbo fuel pump with malpassi fuel reg saab turbo bov

It is easier to build up a 120Y engine instead of a 1200 engine as the alternator is not on the exhaust side

frankthedolphintrainer

Weber 32/36 blow-thru with frankthedolphintrainer turbo manifold

Empson

A series suck through turbo setup by James Empson (twitch@bigpond.com) 2008/05/01 Datsun B10 coupe

The turbo is an IHI - RB6, originally off a mitsubishi Galant 2 litre. the exhuast manifold is off an A15, with a flange welded onto it. The inlet manifold is suited to an Oval port head, the SU is a 1.5 inch.

datsonovic

Zenith-Stromberg 1.75 with T04 turbo

oan78

A12 Sedan with Weber and Hitachi turbo

A12 wagon with 175 Stromberg and Mazda 20B turbo

rice

For maximum boost, use a large turbo. Lag is heavy, but still operable.

* Drawthrough * 45 Weber DCOE carburetor * T4 turbo @ 10 psi * Compression ratio: 8.2:1

Photos

See Turbo Manifold Photos Turbo Photos 1 Turbo Photos 2 Intercooler Photo Index

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)