Tuning is a Must. You don't want to be one of the yahoos driving around belching black smoke all the while feeling proud that your car actually runs. With the Weber 32/36 Carburetor you can have it both ways -- with a little bit of effort, you can have power and economy both. You will need to 1) adjust the carburetor correctly and 2) tune it for your specific engine with a Performance Jetting Kit. It is a selection of jets to fine tune your power and fuel efficiency.

Contents |

Tuning Overview

It is recommended to change the main jets only. However when swapping carbs to different engines, changing the air jets may be called for. See a Holley tuning book for more details.

Weber DGV (32/36) Holley 5200/G180 is a licensed copy

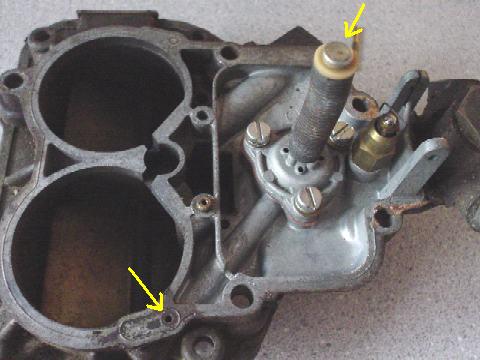

All Webers have 26/27 venturis. But Holleys have various size venturis. What follows in this article is for a 26/27 venture Weber DGV or DFV, unless otherwise noted.

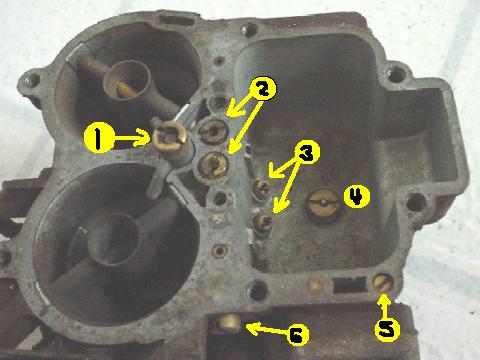

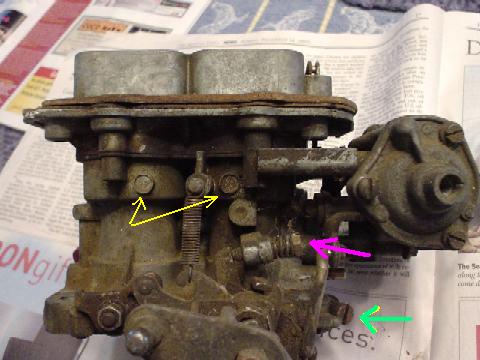

Check which venturis your Weber has. YELLOW ARROWS point to the sizes:

Spacers in the power valve. Little plastic rings can be fitted or removed to chage the vacuum point of the power valve. Most open when vacuum drops to 6 inch mercury (Hg). This affects the primary side only (secondary side is enriched by restriction in the top cover).

Accelerator Pump cam: varies. In addition, most have a three position lever which can be used for tuning. Using the lowest hole increases the amount of fuel pumped. For low-RPM wide open throttle you can drill out the pump nozzle (and lower the level pin to compensate).

Holley Models

Jets: 1970-1975 models used brass jets marked with the bore size, for example 150 means 1.50 mm. These are not flow checked and so a 145 and a 150 may actually flow the same. 1975 and newer green jets are tested and marked for actual flow rather than hole size.

Carburetor Adjustment

Float setting notes

- Fuel pressure is critical to float spillage. Redline recommends 2.5 to 3 lbs

- For aggressive off-road float drop should be limited to 44 .5 mm max drop

Reference: redlineweber.com parts breakdown

Carburetor set-up and lean best idle adjustment

Baseline settings (to get your engine started)

- Speed Screw 1 to 1-1/2 turns

- Mixture Screw 2 turns

IMPORTANT: Adjust the float level before messing with the idle screws.

After you get the engine started and warmed up, adjust the idle mixture exactly as you would adjust the stock Datsun carburetor. The Weber DGV is adjusted the same way.

Idle Speed and Mixture Adjustment

NOTE: Idle speed must be adjusted with engine fully warmed, choke butterfly fully open. Take off air cleaner lid and confirm the choke is fully open before proceeding.

- Verify that choke if OFF (choke flap is fully open)

- Adjust curb idle speed to 750 RPM

- Mixture adjustment. This will make any stock Datsun run nice:

- Adjust idle to 775 rpm

- turn mixture screw in (clockwise) to lean the mixture down to 750 rpm

- Just learning? To get a 'feel' for this adjustment, turn the screw by half turns clockwise and anticlockwise till you hear the engine speed up and slow down. Then fine turn with 1/4 turns. Do this repeatedly until you are confident of the results

Fast Idle: this is part of the choke adjustment, and isn't done with the engine warm. See the Choke section.

Also see redlineweber.com: Carburetor set up and lean best idle

Jetting (Tuning)

You will need a Performance Jetting Kit. It is a selection of jets to fine tune your power and fuel efficiency. You don't want to be one of the yahoos driving around belching black smoke all the while feeling proud that your car actually runs -- you can have power and economy both with a little bit of effort.

Are you OK with 100hp and 13 mpg and "runs good"? Or would you rather have 100hp and 28 mpg and "runs best"? Tuning your carburetor can increase fuel economy, get rid of black smoke -- and still make the most HP.

Top-End Performance of Hollywood sells Redline Weber kits. Here is the jetting they list for the performance 32/36 kit for A-series engine. Presumbly this is for a stock engine:

Carb: 32/36 DGAV or 32/36 DGEVPart #: 22680.033B Venturis: 26/27 Auxiliary venturis: 3.5/3.5 Main jets: 140/140 Emulsion tubes: F50/F50 Air correction jets: 170/160 Idle jets: 60/50 Pump jet: 50 Needle valve: 2.00

If you buy a kit for your specific engine, it will run fairly good out of the box, but should still be tuned to match your engine. If you obtain one second-hand, count on swapping jets, emulsions tube and other tuning parts to make your engine run right. Black smoke, smelly exhaust, jerky acceleration and poor fuel economy is what you get before you tune it. It may "feel powerful", but you can make it run even better with some patience and the right parts. You can get the tuning parts from Redline:

- Jets

- emulsion tubes

- throttle pump nozzles

For proper tuning, it is important to evaluate all of these:

IMPORTANT: If you push down on this spring-loaded power valve actuator, then sucking on this hole should keep it pulled down. If instead, the hole leaks, you won't be able to tune the carburetor correctly. Replace the diaphragm.

anb008 had his standard A12 with Weber 32/36 carb rejetted and dyno'ed. The jet settings are:

Compare Venturi size to Optimum Carburetor Choke Size

Primary mentioned first, then Sec...

Air Correction: 175/145

Fuel: 120/145

Emulsion Tube: F66/F66

Choke Tube: 3.5/4.5

Idle:

50/55

Since all Weber DGV/DFV (and DGEV/DFEV or DGAV/DFAV) variants use the same 26/27 mm venturi set, the main jetting is identical to achieve max power at full throttle -- for any engine.

Secondary Main Jet/Air Corr Jet 140 & 160 or 135 & 160 (a bit richer)

Either one will make very good power at full-throttle and higher RPMs. The richer jetting is good for lesser throttle or RPM with longer duration camshafts.

L-series engine

This jetting is the baseline for any L16/L18/L20B, even in the 521 or 620, 510 etc. Here is the Weber DGV (32/36) jetting for a stock 510 with L16 engine. Works fairly good with an A12 also.

Main Venturi: 26/27 Aux Venturi: 3.5/3.5 Main Jet: 140/135 Em Tube: F50/F6 Air Corr Jet: 165/160 Idle Jet: 55/50 Pump Jet: 50 Needle Valve: 2.00

Weber 38/38, DCD or other Downdraft will be different.

Weber D**V tuning as a systems engineer

B210sleeper:

I've had a weber dfav ( holley 5200 whatever ) for about a year now, and I thought that the procedures for getting it running right were needlessly obscure. Baselines** these values = +/- one step are a baseline. The car will run like this, not ideally but you could.

main jet 140/145 Air Corrector 165/175 E-Tube f6/f6 Idle jet .45/.50 Idle Air 1.50/0.70 idle mixture screw 2 turns CCW from bottom Idle speed ~ 1 1/2 turns from first contact Definitions: I feel that some explaination of the jets would be helpful.

Main Jet: This is in the fuel bowl, it controls the maximum amount of fuel to enter each circuit . It has final control over the mixture at WOT, since if it's too small you will always be lean no matter what you do. Likewise too big and you'll be rich to the point that you can't compensate.

Air Corrector: This controls how much air flow it takes to activate a circuit. Means if you should keep changing these down till you develop a flat spot in the throttle. there can be as many as 3 distinct flat spots, you'll probably only ever experience 2, the first caused in the primary at about 80% throttle and extending to lower percentages as it gets exceedingly larger. The second is in the secondary the remaining % of throttle range starting at WOT and extending down as it continues larger. The third is caused by those idle air correctors, but those should never be messed with, you can't even order them. But if you had a pesky idle problem, you might want to find them and make sure they're installed, not blocked, etc... A flat spot around 2000 rpm would be idle jets too small.

E-Tube: Misunderstood emulsion tube, it's a complicated part that regulates the A/F ratio. The number of holes and where they occur, work it's magic. They are found directly under the air correctors and shouldn't be mucked with. Make sure they're baseline.

Idle jet: It's the idle jet which controls how much fuel is delivered at idle. It won't significantly effect the AF ratios for driving. Fix idle problems here. One thing... If you've reached a very small idle jet you might want to use larger ones and lean down the main jets ( tiny idles plug easily and that would be annoying ) A flat spot around 2000 rpm would be idle jets too small.

Idle Air Corrector: Suppose your car just won't idle but otherwise ran fine, this would be why. It also might be responsible for cars that idle at 2000 rpm and can't be slowed, because it's missing or plugged. You shouldn't need to touch these.

So now you understand what the parts do.

Setup priorities:

- eliminate vacuum leaks

- install a secondary fuel filter of some kind to capture tiny particles that seem to end up in the carb no matter what.

- set advance. Webers seem to like lots of advance, so give it all you can ( don't detonate, don't give it 30 deg static, be reasonable, I have 7 static and it's pretty good, as much as 12 )

- make sure you're using ported vacuum (off the carb body ) if you're not using it understand why.

- Set idle mixture screw = 2 turns out

- set idle speed 1 1/2 turns out

- try to start the car

- let the car warm up... a challenge perhaps, but it needs to be warmed up

- if it runs turn idle mixture screw clockwise till the car runs worse, then turn counter clockwise till the idle speed picks up, somewhere in there will be a point that sounds best. If that point is making it idle super fast turn the idle speed down, you should be able to get the idle down ( if not that's a symptom of something. )Don't worry too much about how much in or out the screw is, the sharpness of the point at the end of it has changed over the years, so if it's more than 2 1/2 turns out it may not be as bad as it once was. If the car is making a noise like sucking the bottom of a cup with a straw, then your fuel bowl level is too high, either the needle valve is stuck, or it's leaking or someone didn't tighten everything down, but it'll be running too rich and the gasket will probably be wet when you take it apart.

- so you've made it past idle setup, now blip the throttle a bit in neutral, do it slow and mind your rpm, does it gain rpm smoothly and not bog or have other issues up to 1/4 throttle? If so then you can try to drive it, don't go far, don't go in traffic, go down the block, take notice of how the car responds from a dead stop, you probably wont get past 1/2 throttle, any flat spots? if the flat spot is idle - 2000 rpm then it's likely that your primary idle jets are too small. if there's a flat spot further up in the range it's the primary air corrector being too large. Don't worry about WOT at this stage.

- Go back home and make adjustments needed based on that road test, take note of how the car shuts off too. Webers without anti-dieseling solenoids are fussy and tend to run-on. But shouldn't backfire, or afterfire (one is out the carb and the other is out the tail pipe, having a catylitic converter will make this a problem )

- Having an EGT ( exhaust gas temperature ) gauge will help with this part, otherwise it's butt dyno or the real dyno. You can also use O2 gauge if you have one a/f meter. You've made it this far you're almost there. Now is secondary circuit tuning, you can only do this at WOT, so take that in mind when choosing a place. Your air correctors default value is from a 2 liter engine, so you will need to make them smaller, just keep making them smaller till that WOT flat spot goes away. Your smaller engine needs less fuel than the 2l default values, so you'll want to make the fuel jets smaller too that will make the mixture leaner. If your idle jets are really small, make the fuel jets smaller instead, and bring the idle jets back up a size or 2.

You should now have a car that is quite a bit snappier, it may be very touchy now, i suppose the final call comes out to what you like to drive, but you'll understand how to change things now.

At this point you may want to take the car to somewhere with a wide band emissions monitor and a dyno and perfect it, but you'll have a running car in any case.

Also See

Also See: * Air-fuel Ratio Gauge

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)