[< Previous 3836 3837 3838 3839 3840 3841 3842 Next >]

[< Previous 3836 3837 3838 3839 3840 3841 3842 Next >]

The comments are owned by the poster. We aren't responsible for their content.

| Poster |

Thread |

| Dodgeman |

Posted: 2006/10/28 13:10 Updated: 2006/10/28 13:10 |

No life (a.k.a. DattoMaster)   Joined: 2003/6/27 From: Southern Tablelands N.S.W. Australia Posts: 8287 |

Re: offset ground crank In most cases you would simply use standard undersize bearings, however this varies from engine type to engine type.

An example of this was the old side valve Mercury engines. [1939 to '48] They used a larger crankpin size than the very similar 'Ford' engine, so it was a simple matter to source a set of Ford rods & offset grind the Merc crank. The Ford bearings were for a 1/8" smaller journal so the crank was offset ground to the standard Ford journal diameter & a 1/8" [just over 3mm] stroker job was achieved without special parts. If the engine was bored 1/8" you got what became known as an "Edelbrock standard" bore & stroke.

Naturally, whenever different components of different specs & mass [weight] are used, then a comprehensive balance job is highly recomended.

There are many ways to skin a cat with stroker jobs & doing your homework beforehand can save a lot of grief.

If you use an A14 crank in a low deck A12, A12A or short stroke A13 block with the A12A or A13 rods, then the use of the lower crown A15 piston will go a long way towards making it all work. The A15 piston will still need machining, but only a little.

Offset grinding an A15 crank by .5mm means that 1mm oversize bearings [for an undersize journal] are needed & you would need to machine .5mm from the top of the piston to restore deck height.

This would give a 1mm stroke increase & with a standard bore the capacity would increase from 1488cc to 1506cc.

It would be wise to check the clearance of the rotating parts to the block as it gets a little squeezy in there, even in a stock A15.

If you used the maximum standard overbore of 77.5mm, the capacity would become 1566cc.

|

|

|

|

| Poster |

Thread |

| D |

Posted: 2006/10/28 15:48 Updated: 2006/10/28 15:48 |

No life (a.k.a. DattoMaster)   Joined: 2002/10/28 From: under the Firmament LOL no twiglight effect BS Posts: 10994 |

Re: offset ground crank If you find or get made the lowest pin height pistons possible you can probably go as far as 85mm stroke for 1604cc with the 77.5mm bore. Using the taller a14/a15 block will be the only way to fit decent length rods with the lower height pistons. A better way to get 1600cc rather than all the trouble of going weaker 79mm bores. smaller journal rods could be sourced from motorbike or even the tiny e15et ones.

If only we could get a copy of the database software crankbuilders and piston mobs have.

Anyone know the name of the software?

The sr20 and L20 engines have 86mm strokes and they rev quite well. Even the sr20 has quite average rod stroke ratio.

Up to 90mm stroke could be used with a modded e16 crank but the A14/15 block is probably not tall enough.

|

|

|

|

| Poster |

Thread |

| kegs |

Posted: 2006/10/28 10:39 Updated: 2006/10/28 10:39 |

No life (a.k.a. DattoMaster)   Joined: 2003/1/5 From: campbelltown (sydney) australia Posts: 1802 |

Re: offset ground crank wat would be the advantage of this, some sort of stroking???

surelywould make the whole engine out of balance ???

|

|

|

|

| Poster |

Thread |

| pager |

Posted: 2006/10/28 11:48 Updated: 2006/10/28 11:48 |

Home away from home   Joined: 2003/3/21 From: Tamworth, NSW Posts: 850 |

Re: offset ground crank  Yuo would need to make new big end bearing caps etc |

|

|

|

|

| Poster |

Thread |

| blofly |

Posted: 2006/10/28 12:01 Updated: 2006/10/28 12:01 |

Home away from home   Joined: 2005/9/5 From: Bunbury Western Australia Posts: 668 |

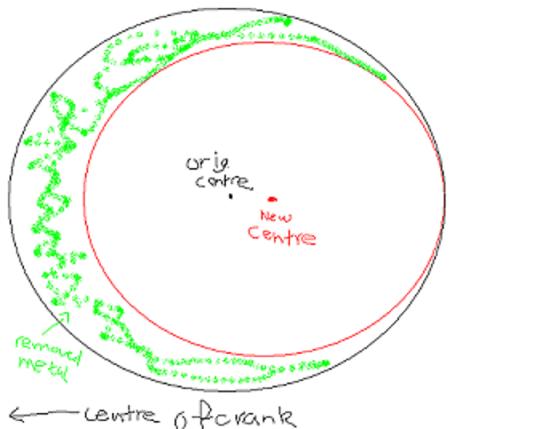

Re: offset ground crank I see how it works now you would need smaller inside diameter and stock outer diameter big end bearings and the benefit of doing this would push the piston higher into the head for more comopression, example if you have flat tops and offset grind the crank you would get more compression by pushing the piston up past the head gasket, maybe only a milliemeter or so

|

|

|

|

|

| Poster |

Thread |

| sidedraught |

Posted: 2006/10/28 12:12 Updated: 2006/10/28 12:12 |

No life (a.k.a. DattoMaster)   Joined: 2004/9/4 From: sydney Posts: 3098 |

Re: offset ground crank Not only is it going up higher but it is going down lower increasing the stroke thus giving you more cubes.

|

|

|

|

Misc

Misc

0.00 (0 votes)

0.00 (0 votes)

Yuo would need to make new big end bearing caps etc

Yuo would need to make new big end bearing caps etc