No life (a.k.a. DattoMaster)   Joined: 2008/10/10 From: Melbourne Australia (and likely under the car) Posts: 1021 |

Re: L series clutch plate on a15 flywheel It would honestly be close to impossible to answer (for me at least) without knowing the diameter of the clutch disc you have, and the pressure plate clamping force, and the friction co-efficient of the clutch plate lining.

Unfortunately there's some variance in that friction lining and pressure plate force from clutch manufacturer to clutch manufacturer, so you can find a slightly smaller clutch from one place better than a larger one from another, but within any specific brand, wherever possible, and within the limits of the realistic options we are discussing here - well you'd tend to go with the biggest diameter you can fit, and decent pressure plate clamping force, and then you can run a friction lining that lasts and doesn't chew up the flywheel or anything.

Or if it's for a racer (but not a mega buck small diameter multiple place clutch setup), again you'd go with the bigger diameter (biggest you can fit) and decent clamping force (higher than std, since you don't have to sit in traffic for half an hour on and off a heavy clutch) and possibly even non standard lining.

Having said all that - often for 'performance' cars they came out with an uprated pressure plate or clutch plate, and aftermarket manufacturers followed that pattern. For example - the old holden red and blue 6 cylinder motors. The red had a slightly smaller clutch, the blue a bigger diameter (fit on basically the same diameter flywheel, but the blue pressure plate won't clear the inside of the red motor bellhousing). So you'd think with the 1/2 or so extra diameter clutch plate, the blue was 'the best'. Well, in actual fact, the red motor 6cyl powered holden 1 tonner (light commercial tray packed pickup truck sort of thing, for the overseas readers) came out with a much heavier pressure plate clamping force, so was actually the pick of the standard clutches for performance use. Naturally if you went to something more custom made, you could run the blue motor diameter and an uprated pressure plate and get something even better, but out of the off the shelf stuff, the one tonner clutch was it.

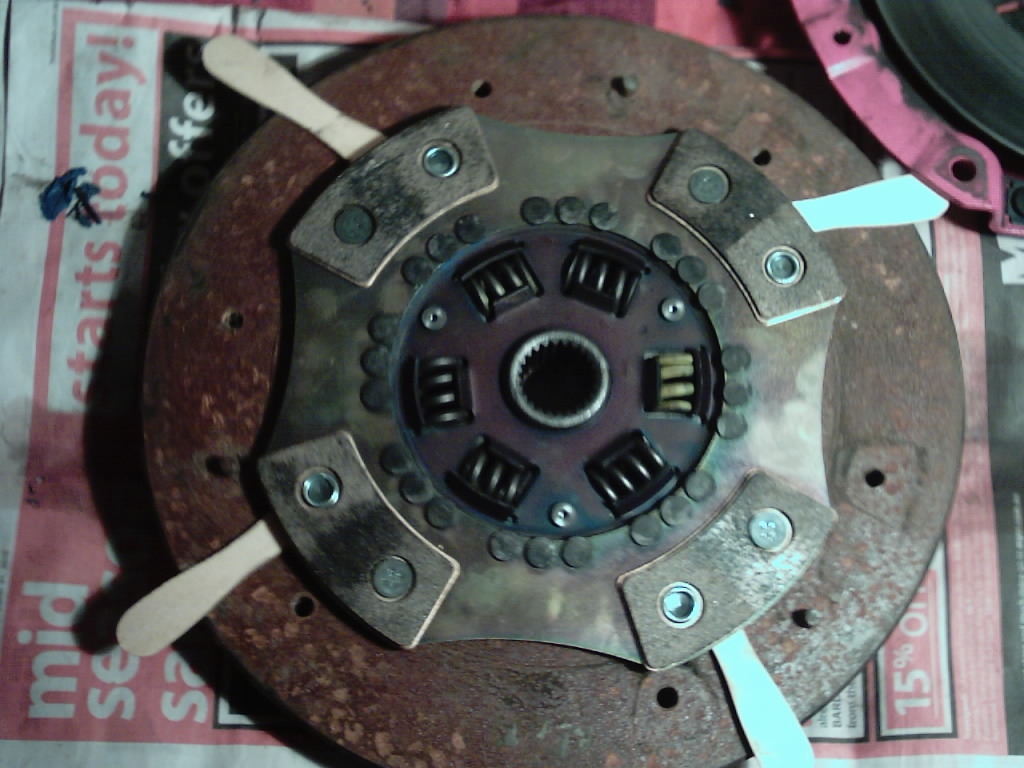

So with that in mind, based on what the exa turbo was, it likely had a better clutch than the a series, and probably on par with the larger L series. This is where it gets tricky - the plate in question here is not the biggest L series plate - it's the 'middle' one which just fits on the a series flywheel.

It'd probably be difficult to pick without actually trying both (any chance of a pic of your clutch?)

About the best short version of all this would be - 'it depends' but furthermore 'if what you have now is working, it's unlikely there'd be a big enough difference to justify trying an L series clutch at all. If it aint broke, don't fix it sort of thing.

At this stage, it's still early days (for my attempt on this conversion at least, obviously others have been there done that) I'm not 100% certain the 180mm L series clutch is a goer. It's possible that by the time the bellhousings are grafted onto each other, that there is insufficient clearance for the L series pressure plate to fit in there. I'm hoping it won't be the case, but I won't know for a little while.

I'm also yet to contend with a few other issues - namely shifter position (I actually want it a lot further rearward, since I've altered the drivers seat just to get enough legroom etc. ) which might require rearward relocation of the handbrake lever. And then there is the tunnel mods if needed.

|

Mechanical

Mechanical Drive Train

Drive Train

0.00 (0 votes)

0.00 (0 votes)