|

|

| Re: racetech's 1200 SR20VE Project |

Subject: Re: racetech's 1200 SR20VE Project

by racetech on 2010/7/22 12:09:19

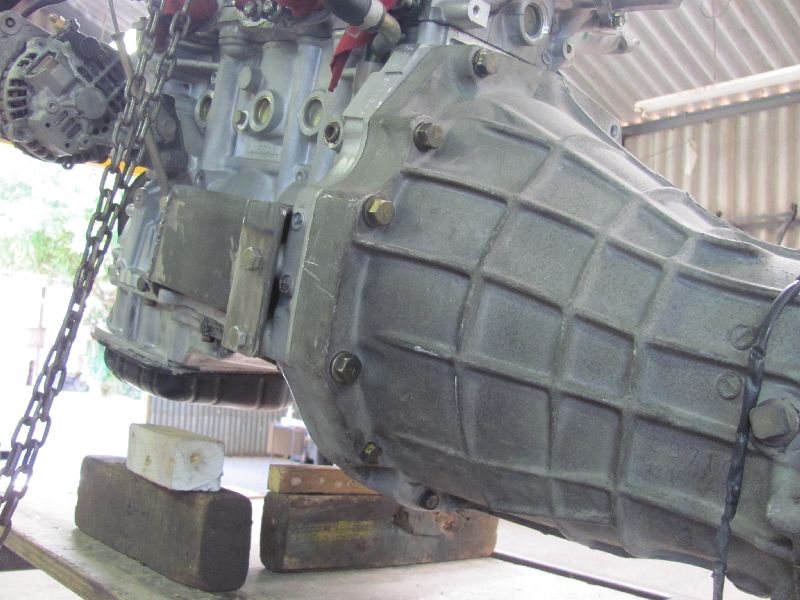

24 April 2010 – SR Power Mounted & Floors Removed

One of the biggest challenges right from the beginning of this motor and gearbox combination was the alignment of the bell housing bolts, if you take the standard motor and gearbox, only 4 bolts on the right hand side is in alignment, this meant I had to make a adapter plate, something I was not looking forward to. Rezlo ([img]http://www.rezlo.com">www.rezlo.com</a>), well known SR guru in South Africa advised me to use the RWD upper oil pan from the S14 SR20DET motor. After sourcing one it quickly became apparent that this is the way to go as know 8 bolts was in alignment, 4 on the right and 4 at the bottom, luckily the 4 most important bolts on the bottom was covered.

While the sump and upper Oil pan was off, I noticed the condition of the motor on the inside, no sludge, clean oil with no debris, absolutely no sign of any white metal or other metal particles in the sump.

The other interesting thing was the half counter-weighted crank, probably the reason why the VE motors has the tendency to rev very high, well higher that the building block motor the SR20DE. After some additional home work, it became quite apparent that the VE also boost lighter internals like the rods and pistons.

Cross member was removed and the old A12 mounting uprights was cut off. From sheet metal new uprights was designed and build. These were placed at a angle to facilitate the installation and removal of the motor. New engine mounts had to be designed as it was not included with the motor, so the serious mild steel sizes was pulled from the shelf and we got started on the mountings, we wanted to support as much as possible over the largest area, thus the strange looking mountings. Looking back this may have been a bit over the top as there is no weak points in the mountings itself that could aid in the case of a accident to absorb shock.

The old floors in the car was due for a replacement and the bigger S14 gearbox also meant that we would need to enlarge the transmission tunnel, due to this we decided to remove the floors and transmission tunnel and start from scratch as it would be easier than struggling with old pieces of sheet metal. We started with the floors, cutting away everything that had rust damage and bad dents followed by the transmission tunnel. After some careful measurements we started with the firewall and while we were at it also the old pedalbox mountings, as this was due for replacement by a forward swing bias adjustable unit. Motor and gearbox was again installed and the final part of the transmission tunnel removed.

Anybody else considering a conversion like this, here is a picture of the SR20DET RWD flywheel and the SR20VE Automatic flex plate. The ring gears is exactly the same. The reason way something like this was of interest to me was the fact that I'm planning on using the original FWD started mounting with the RWD gearbox. Main reason for this is that I can keep my block original and use the FWD starter that I got with the motor. Only problem with this is the fact that you need a expert to remove some material from the outside of the flywheel to get the FWD starter to fit over it, also a smaller pressure plate need to be used with the RWD flywheel.

|

|