|

|

| Re: racetech's 1200 SR20VE Project |

Subject: Re: racetech's 1200 SR20VE Project

by racetech on 2010/7/29 8:58:55

29 May 2010 – Transmission Tunnel Finished

Work started with bending and shaping the two front covers that is located in front of the main piece of the transmission tunnel. They were welded in place and then the bending and shaping of the rear section that mates between the main transmission tunnel and the old one started. This particular one took quite a while to get satisfactory results, as we were working with old and new metal and had to get them nicely blended in to each other.

Once all the TIG welding was done on the inside, the old man moved to the underside of the car to do all the welding there, this was a heck of a big job and kept him busy for the rest of the day. As he had to weld the channels to floors, floors to transmission tunnel and all the other pièces in the puzzle. You can actually see him busy welding on the underside while I was taking the photos of the inside, it appears as a bright orange light as the metal heats up. While he was busy I cleaned all the inner welds with the grinder fitted either with a cutting disc or flapper wheel. I must say the flapper wheel gives a real nice finish. All the new metal parts is now double seam welded on the inside and outside of the car.

The following day I spend to apply paint to all the seams, new metal and old metal that will stay on the car. All of this was done in preparation to seal all the seams with polyurethane based sealer. In this process another bad patch of rust was discovered just in front of the left rear wheel. Another item added to the list to be fixed.

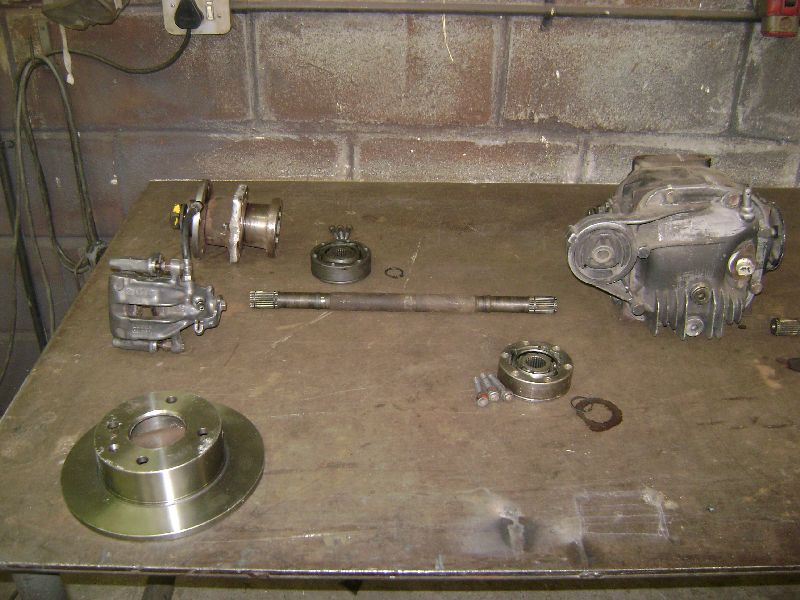

I had a hour or two of time on my hands after the painting and decided to do the machining on the hubs to fit the rotors sourced from a Ford Bantam Bakkie, afterwards I packed all the components of the rear suspension out on the table to start with the planning of the rear suspension. The components on the list is BMW E30 3.64:1 Limited Slip Differential, Ford 3.0Lt Sapphire Hubs, Hub Carriers, CV's and Drive Shafts, braking on the rear will be handled by a set of Volkswagen Golf III GTI calipers on the set of Bantam solid rotors.

|

|