|

|

| Re: racetech's 1200 SR20VE Project |

Subject: Re: racetech's 1200 SR20VE Project

by racetech on 2010/8/2 8:34:22

24 July 2010 – Rear Suspension Planning - Phase 1

Never in my life will I again under estimate the amount of planning that goes into building your own rear suspension. First you need to decide which configuration will suite your application, I went for the SLA (Short Long Arm) Independent Rear Suspension option, this configuration will provide you with some form of negative dynamic camber as the wheel travel upwards. Next in line is the differential to be used, well this was a easy one, BMW E30 3.64:1 Limited Slip Differential as I had one lying at home gathering dust. Now you have a differential, next in line was the Hubs, CV's, Hub Carriers and Drive shafts, I'm not the biggest fan of Ford, but must admit that the old 3.0 Sapphire solved this piece of mystery. Mounting these parts needed some thinking, luckily this weekend I was able to design the Upright in such a way that a 13" wheel could be used, this upright will be the mounting plate for the Hub Carriers, Upper and Lower Wishbones and the calipers which was sourced from a Volkswagen GTI III rear suspension. Rotors come in the form of Ford Bantam bakkie's front solids.

The wishbones was a beast in their own, I decided to use bushes instead of ball joints, sourcing bushes was much easier than figuring out which bush to use. Fisrt of all you need to know exactly what sizes pype you will be using on the outside and inside of the bush. I settled for 34.2 OD X 25 NB X 2.84 SABS 62 MED WT pype for the outside of the bushes, this Pyp has an OD of 34.2mm and ID of 28.52mm Wall of 2.84mm and for the inside of the bush a Seamless cold drawn hydraulic steel tube with OD of 16mm and ID of 12mm. With this selection of pypes I was enabled to source a Polyurethane bush that has a OD of 28mm and ID of 16mm Length of 25mm and I will be able to use a 12mm bolt to secure the wishbone. The body of the wishbone will be made from ASTM A106 GRB SCH40 OD of 33.4mm ID of 26.64mm Wall of 3.38mm, this selection of material will be a good combination between strength and weight if working on a budget, chrome molly would have been great, but at a price only the top teams can afford.

Hub carriers and Hubs was machined to allow the use of Allen Cap Bolts instead of the conventional press in studs. I will tap thread in the hubs and tighten the Allen Caps with Locktite and than spot weld it to keep it in place. A 4/100 pcd template was machined to drill the holes in the hubs which currently is 4/108pcd.

The front track rods was also modified to be adjustable, this would enable me to adjust the front castor in conjunction with camber / castor plates to a exact number that will suite the application or conditions.

Some rust was removed in the boot and the rear tow bar mounting was reinforced for use as a possible mounting for the rear suspensions sub frame.

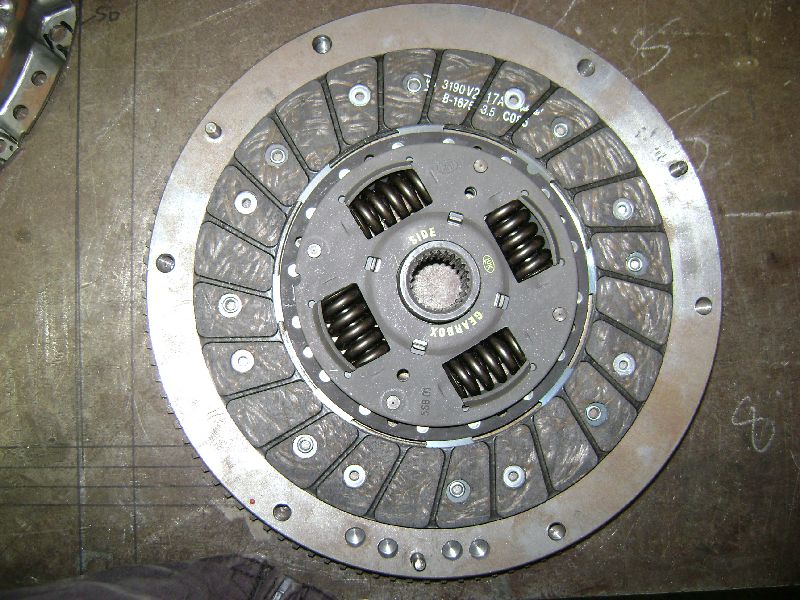

Flywheel and Pressure Plate came back from the machine shop that did a very good job on removing the material behind the ring gear which was the obstacle for the FWD starter and the balancing of these 2 units. We quickly bolted it to the motor to see if the starter will fit, and yes it does. Even when placing power on the solenoid, it kicks in and release. We then bolted the gearbox to the motor and mark the material that needs to be removed in order to use the RWD gearbox with the FWD starter. After a few fitments we had enough removed for the starter to clear the bell housing and not to make a hole thru the bell housing.

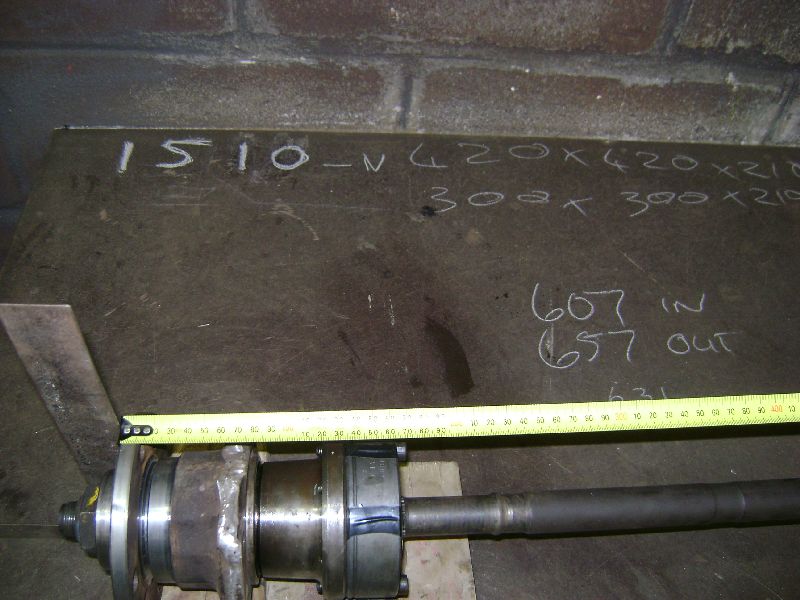

We moved our attention back to the suspension planning, first of all we assembled the suspension in a mock up form on a table to measure the track which ended at 1510mm without wheels for the combination of BMW and Ford part. One interesting part is the inner CV's/Lobro Joints, there bolt pattern is exactly the same as the BMW flanges, just the holes on the flanges sits at 10mm and the Lobro at 8mm, redrilling the Lobro's solved that problem. We build a suspension troubleshoot tool to help us determine the lengths of the upper and lower wishbones, after playing with a few different configuration we settled on getting the differential mounted as this is the most important part, then it will be ease to measure the lower wishbone length at it is the one that determines were the wheel wil sit. The upper one we can move around as we se fit to get the desired effect on camber and travel. A lower differential frame was designed, while keeping in mind the mountings of the lower control arm and the ability to adjust toe on them and the amount of effort needed to remove the differential.

Over the weekend I got a lot of respect for any Fitter and Turner, it took me more or less 3 and a half hours to cut the outer wishbone pipes, machine down to 61mm and chamfer both sides inside and out, and another 30 mins on the lathe to dril 12mm holes in 4 pieces of MS shafting and machine down 2 pieces of pyp that will acts as spacers between the differentials upper mounts and top plate.

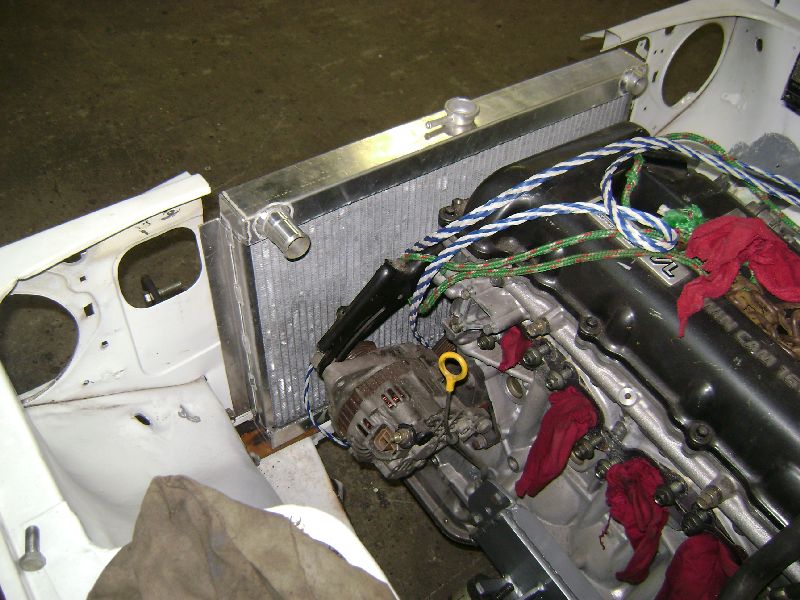

Since the radiator and oil cooler arrived, I could not resist the temptation to do a quick mock up install of it, just to make sure the radiator is the correct size this time round. Never in my life will I support the guys at The Radiator Specialist in Parow again. The first one took them a week to build, after I showed them that their reading skills was not up to par, as they read the 440mm cap fitted on the drawing as 480mm, it took them a month and a half to build a new one. But the best of the whole ordeal was the cheak of the owner telling me that I need to get a buyer for the one they build to big after I supplied them with a drawing that they obviously mis read or just ignored. Do we as clients really need to think for the experts in their field to these days, there is just no proud in workmanship anymore, non what so ever. To add to it, the second one was manhandled, the core is full of marks, I will need to sit down with a screw driver and correct it. I can write a book about this place, but lets leave it there and not support them again. The radiator made as the drawing stated was perfect, some people just have the ability to use a measurement instrument, the bonus of the custom made unit is that the top water hose will only require a 90 degree pipe. We then noticed the ideal placement for the oil cooler, on the right hand side next to the radiator. This will keep piping to a minimum and the routing of them will also be allot easier.

A few other parts also arrived since the last visit, for a whole month I only collected parts and no work was done.

1. Custom Made Aluminium Radiator Length 620mm x Height 440mm without a cap, basically the biggest I can fit to the Datsun. The workmanship on the unit is very good, but the way they handle parts is shame, better packaging would have prevented a lot of the marks on the core.

2. Setrab 13 row Oil Cooler, 330x99x50mm with M22x1.5 - female fittings. The only available oil cooler in South Africa that you can decide which fittings you want to use on and that was the correct size to fit my application.

3. Reverse Swing PedalBox from Southwest Speed in the States. This piece of kit comes with brake and clutch pedal. Mountings for 3 Master Cylinders, 2 for the brakes, one rear, one front with adjustable balance bar and one for a hydraulic clutch

4. Brake Bias Adjustor - Cable Type that fits the above mentioned PedalBox

|

|