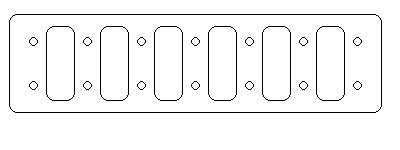

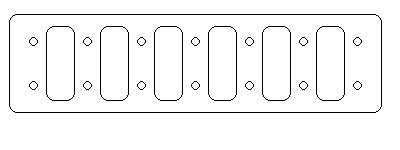

to make a stud girdle, you basically just get a sheet of approx 10mm thick steel, and mill out the 'slots' to make clearance for each rod/crank/counterweight, and get longer than standard main studs.

you then machine down 'top' of the main caps if necessary - to make them flat across the top, so the girdle can bolt down evenly across the cap (and this actually makes it stronger as there is more support of the main cap with the girdle on top. You don't just machine the main caps as is, as theoretically some could be a little taller than others (since for a std application all that mattered was that the holes/crank tunnel were all aligned . So you mill the whole lot to get them even so the girdle fits

Obviously the holes drilled through for the studs to go through on the girdle - do them slowly and accurately so that you keep them a firm fit (not too tight that it jams or sticks, but just enough room to allow it to be fitted)

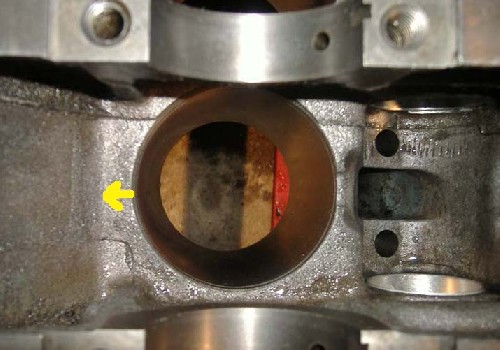

sorry for using a pic of an inferior motor :) (the holden red 6) and further to that, although I've done a bunch of holdens over the years, this was not mine, I actually got the picture from someone else on the net years ago (and I can't remember who it was anymore!)

Anyway that gives the basic layout.

Obviously with stuff like this, you might have to make the front or rear one a little narrower to fit, or you might even have to make a custom sump (sometimes you can get lucky and get 2 stock factory sumps and cut them and join them back together to make more clearance, but you also have to find (by trial and error) whether you can get that to fit inside your engine bay/cross member.

Still, if you're chasing 280bhp, that might just be the way you have to go.

There is another 'stage' you can go to with stud girdles. You basically still do the one like in these pictures, but then you add 'legs' that go from the 'boundary' of the main girdle, and reach out and up to two new rails that go where the sump bolts on to, and you then use countersunk socket headed capscrews (bolts using an 'allen key' to tighten them, and a countersunk head so the bolt will fit flat with the 'new' sump rails. that ties the mains to the outside of the block as well (this is actually more important on holdens, potentially, as they tend to break the mains around the area where the cam is, as it isn't as well supported as the other side).

I don't think that this would be necessary - a 'regular' or standard main stud girdle should do just fine. But if you did go to wet sleeves, then I'd definitely be suggesting the one that goes out to the sump rails as well. That actually ends up taking a few hours to build right, so it won't be a super cheap solution, but you might just need it with wet sleeves on an A block.

there's an old story or joke about a young boy asking his dad 'how do they know what signs to put on bridges that say 'maximum vehicle load 30 tons' or whatever weight. And the father says something as a joke 'well son, they just build the bridge, and then drive heavier and heavier trucks over it until it breaks and then they rebuild the bridge and know the right limit.' Now of course that's mostly a joke, but I think in this case, you are getting to the stage where you might just have to test the limitations of the block etc, and might face engine damage that can only be prevented with a stud girdle (of whichever type)

Transfer

Transfer

, a15 turbocharged engine, aiming for 280hp....

, a15 turbocharged engine, aiming for 280hp....

10246.jpg (57.87 KB)

10246.jpg (57.87 KB)