Those "world class" mounts can't possibly break since they are encased in a tube. They are somewhat similar to what most 2017 cars use ...

But rather than re-engineer to mounting system, most used a stronger type of standard insulator

Quote:

These round 'puck' insulators are similar to the stock Datsun insulators. They are rubber bonded to metal plates. But depending on the quality of the rubber and the bond type, some of them hold up much better

According to our wiki article

Upgraded_Insulators ones made of polyurethane (racing type) are recommended -- for racing

Quote:

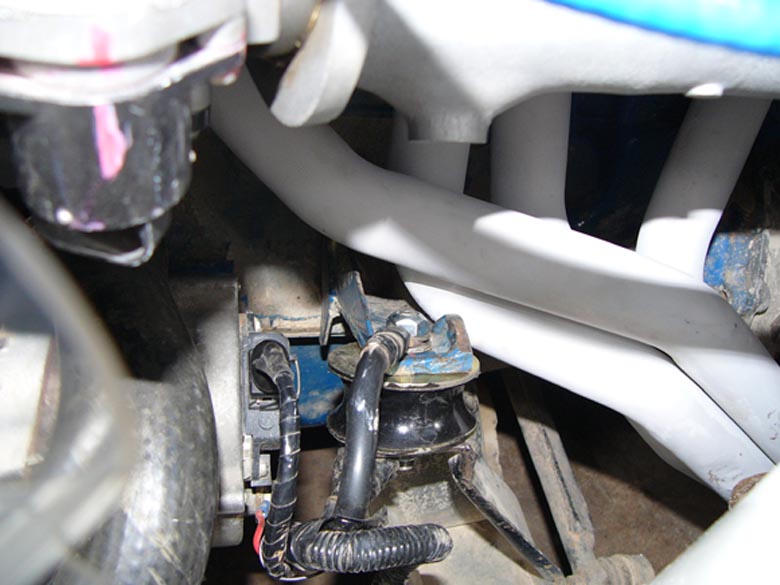

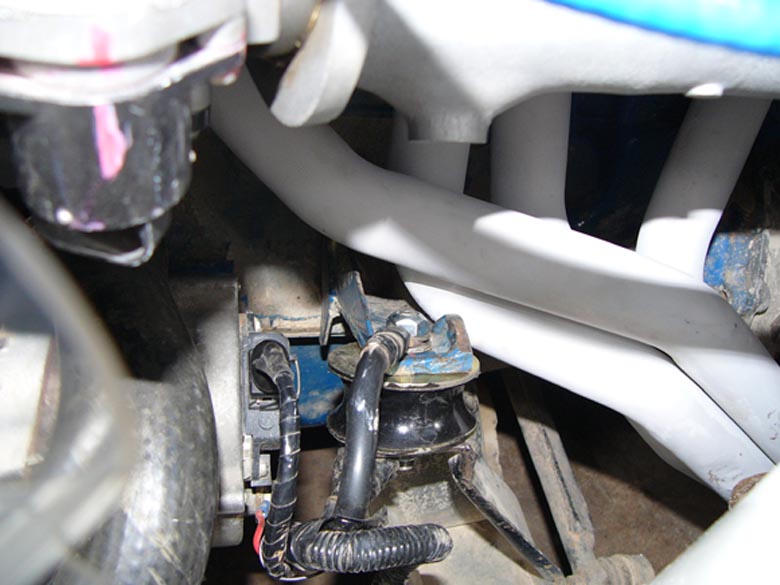

These are the heavy duty engine mounts we were talking about. Broken engine mounts are a common thing in rally cars and this fixes the problem. Mounts are polyurethane and come out of a ford cortina and last for years of competition...Part number MT8156N. Kelpro make them...I usually just go to a good parts place and ask for cortina engine mounts and this is what they give me. Maybe there are two types, these are about 70mm in dia.

Kelpro MT8156N

then there is the revised Maddat insulators, they were made softer to improve durability

More info and part numbers are in the wiki

You don't want to buy them by looks. Some look good, but are no stronger than the factory type. Others look exactly the same but are strong enough for off-road (dirt) racing

Transfer

Transfer