Hey dattoheads

I'm building my A12 as a start, as engine swaps is a bit of a hazzle to get approved here in Denmark.

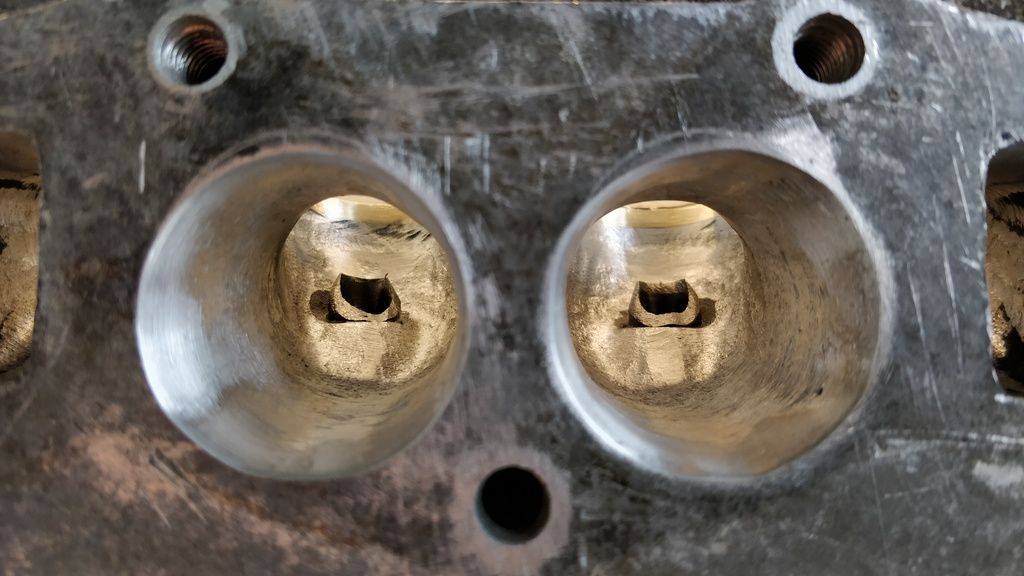

I just wanted to port match, with the intake that I designede, but ended up going to town and doing a full porting

It's going to be supercharged, using a Rotrex Supercharger and might go turbo down the road.

I know that I need APR studs, but should I also get a metal headgasket? The only one availeble is for 79 mm pistons but i have not bored the cylinders out(std 73 mm). And when I'm alredy making and order from Japan, so I'm also buing double valve springs and some other small bits.

Lots of good things came out of the A12 turbo thread that was on a little time back, thats where some inspiration came from :D

Will post pictures of what I have done below.

Thoughts and advise is appreciated ❤️

Transfer

Transfer

exhaust valve.jpg (59.39 KB)

exhaust valve.jpg (59.39 KB)