| Revision as of 01:49, 19 May 2018 ddgonzal (Talk | contribs) (->R) <- Previous diff |

Current revision ddgonzal (Talk | contribs) |

||

| Line 18: | Line 18: | ||

| 1973 testing | 1973 testing | ||

| 1974 NOx | 1974 NOx | ||

| + | 1975 April: '''NAPS''' (Nissan Anti-Pollution System) [[NAPS#Overview|announced]] | ||

| 1975 first sticker used | 1975 first sticker used | ||

| Line 27: | Line 28: | ||

| = NVCC = | = NVCC = | ||

| + | The first to clear the U.S. Muskie Act of 1970 was Honda, with the CVCC engine, which was subsequently used in Honda's first-generation Civic. | ||

| + | |||

| Nissan developed a stratified-charge cylinder head (a la CVCC) in 1973-1974. It was reportedly 2.1 liters, and from a photo looked like it might be an [[L|L-series engine]]. However in the end they were able to meet 1975 emissions standards by using [[NAPS]] instead. | Nissan developed a stratified-charge cylinder head (a la CVCC) in 1973-1974. It was reportedly 2.1 liters, and from a photo looked like it might be an [[L|L-series engine]]. However in the end they were able to meet 1975 emissions standards by using [[NAPS]] instead. | ||

| Line 42: | Line 45: | ||

| <br> | <br> | ||

| <br>''Des Moines Register'' August 1, 1975 pg 17</blockquote> | <br>''Des Moines Register'' August 1, 1975 pg 17</blockquote> | ||

| + | |||

| + | Press Release 1973/10/23: {{search|Nissan+NVCC+low-emission+engine+prototype|Nissan Motor develops low-emission engine prototype}} | ||

| + | <blockquote><hr>「NVCC」エンジンを開発 | ||

| + | <br>––排気ガス規制対策に対処して!–– | ||

| + | |||

| + | Nissan Motor Develops Low-Emission Engine Prototype | ||

| + | |||

| + | (10 . 24 . No.55) | ||

| + | |||

| + | 日産自動車では、かねてから排気ガス規制対策のため、トーチ点火燃焼方式による新エンジン「NVCC」の開発研究を進めてきたが、実験室 | ||

| + | |||

| + | 段階では、ほぼ完成の域に達し、このほど運輸省交通安全公害研究所の要請により試験車を提出して、排気の測定実験を行なった。 | ||

| + | |||

| + | その過程で得られた実験データーは次表の通りであり、国内五十年規制基準値および米国七十五年原規制値を充たす数値が得られた。 | ||

| + | |||

| + | 同社では、この結果に自信を深め将来、実用車とするために、さらに試作実験を重ねることを明らかにした。 | ||

| + | |||

| + | |||

| + | ...</blockquote> | ||

| = 1973 = | = 1973 = | ||

| Line 60: | Line 82: | ||

| anti-emissions devices of the ignition timing control system | anti-emissions devices of the ignition timing control system | ||

| - | = H = | + | = {{Ref|H}} 1975 = |

| - | "H" is the 1975 (50年度) emission standards. Also in 1975 in the United States similar regulations came into effect. | + | "H" is the 1975 (50年度) emission standards. Also in 1975 in the United States similar regulations came into effect. In Japan, compliance was met with [[NAPS]], a combination of [[EGR]] and Catalyst to reduce NOx, CRANK to reduce combustion CO, and EVAPO with charcoal [[canister]] to reduce fuel evaporation HC emissions. |

| {{Photo!|S50_sticker.jpg}} | {{Photo!|S50_sticker.jpg}} | ||

| Line 69: | Line 91: | ||

| {{Album|23894}} | {{Album|23894}} | ||

| - | == EGR == | + | == B210 EGR == |

| - | All B211 (from December 1975) and VB210 (from October 1975) used [[EGR]] Exhaust Gas Reduction. This included Vans which were not fitted with catalytic converters. | + | All [[B211]] (from December 1975) and VB210 (from October 1975) used [[EGR]] Exhaust Gas Reduction. This included Vans which were not fitted with catalytic converters. |

| - | == Catalyst == | + | == B210 Catalyst == |

| Nissan system's of exhaust gas cleaning by catalyzed oxidation ([[NAPS]]) adopted. A 2-way [[wikipedia:catalytic converter|catalytic converter]] converted carbon monoxide (CO) and unburned hydrocarbons (HC) to produce "harmless" carbon dioxide (CO2) and water (H2O). It was only later than CO2 was acknowledged to be a pollutant itself. NOTE: In 1980 the 3-way converter introduced a 3rd reaction to reduce the third major pollutant NOx. | Nissan system's of exhaust gas cleaning by catalyzed oxidation ([[NAPS]]) adopted. A 2-way [[wikipedia:catalytic converter|catalytic converter]] converted carbon monoxide (CO) and unburned hydrocarbons (HC) to produce "harmless" carbon dioxide (CO2) and water (H2O). It was only later than CO2 was acknowledged to be a pollutant itself. NOTE: In 1980 the 3-way converter introduced a 3rd reaction to reduce the third major pollutant NOx. | ||

| Line 79: | Line 101: | ||

| {{Album|23097}} | {{Album|23097}} | ||

| - | No feedback was used to control the fuel system. A carefully tuned carburetor was sufficient. | + | No feedback was used to control the fuel system. A carefully tuned carburetor was sufficient to meet the 1975 emissions target. |

| 20905 CATALYST | 20905 CATALYST | ||

| Line 87: | Line 109: | ||

| * JAPAN GB211 L16 7602- (51 year standard) | * JAPAN GB211 L16 7602- (51 year standard) | ||

| * not used on Van | * not used on Van | ||

| + | |||

| + | Because the very hot converter is located under the passenger seat: | ||

| + | * a temperature warning system is fitted | ||

| + | * seat mounting is modified. [[B210 seats|1976-1977 Passenger seat]] clears the bulge in the floor | ||

| + | |||

| + | Exhaust Temp warning lamp on dash 排気温度警告灯ランプ排気温度警告灯ランプ | ||

| + | |||

| + | [[Relay#25230-89915]] floor sensor relay | ||

| + | |||

| + | Seat for converter-equipped B211 | ||

| + | <br>{{Album|28710}} | ||

| === Unleaded Fuel === | === Unleaded Fuel === | ||

| Line 105: | Line 138: | ||

| {{Photo!|14806-89901.jpg}} | {{Photo!|14806-89901.jpg}} | ||

| - | = B = | + | = {{Ref|B}} 1976 = |

| 1976 regulation including NOx | 1976 regulation including NOx | ||

| <br>{{Photo!|S51_sticker.jpg}} | <br>{{Photo!|S51_sticker.jpg}} | ||

| Line 112: | Line 145: | ||

| * [[Automatic Choke]] to reduce emissions during startup | * [[Automatic Choke]] to reduce emissions during startup | ||

| + | |||

| + | = {{Ref|E}} 1978 = | ||

| + | "E" 1978 emission standard (Showa 53 Year) 53年度排出ガス規制適合車 | ||

| + | |||

| + | == 1200 Choke Warning == | ||

| * Choke warning lamp added to [[Dash#Late]] April 1978 | * Choke warning lamp added to [[Dash#Late]] April 1978 | ||

|  レエン、ワーニング ランプ (アート チヨーク レンズ) |  レエン、ワーニング ランプ (アート チヨーク レンズ) | ||

| - | LENS-WARNING LAMP 24250-H2500 (Auto Choke Lens) | + | LENS-WARNING LAMP [[Meter_Part_Numbers#Sunny_Truck|24250-H2500]] (Auto Choke Lens) |

| - | The dash 'Auto Choke' looks like a blank plate for the choke knob hole. Does it actually light up? | + | The dash 'Auto Choke' looks like a blank plate for the [[Choke_Cable#Sunny_Truck|choke cable]] knob hole. Does it actually light up? |

| - | <br>{{Photo|d3.jpg}} {{Album|27038}} | + | |

| - | = E = | + | Brown mid-model dash |

| - | "E" 1978 emission standard (Showa 53 Year) 53年度排出ガス規制適合車 | + | <br>{{Album|27038}} {{UploadPost|174_5d65ee6af3492.jpg|492391|was=d3.jpg}} |

| - | * NOx reduction via [[EGR#1200|EGR]] | + | Grey late dash |

| + | <br>{{Album|27181}} | ||

| - | = L = | + | == 1200 EGR == |

| - | L - 1981 regulations | + | * EGR comes to the 1200 for NOx reduction. See [[EGR#1200]] |

| - | * [[EGR#1200|EGR]] refined with a VVT valve | + | = {{Ref|L}} 1981 = |

| + | L - 1981 regulations was the reason for the B122 model change. | ||

| {{Album|23169}} | {{Album|23169}} | ||

| - | = R = | + | == Spark Delay == |

| - | R - 昭和63 1988 regulations were applied to the late [[B122]] (R-B122) which arrived in 1989 October. | + | {{Main|Emission_Controls#B122}} |

| - | * NOx reduction via Catalytic Converter. A carburetor with mixture control ([[DFC306|ECU-controlled carb]] + [[Oxygen Sensor]]) is used to make the converter more efficient by keeping the mixture close to 14.7:1. | + | == 1200 EGR with VVT == |

| - | * Exhaust Temp warning lamp on dash 排気温度警告灯ランプ排気温度警告灯ランプ | + | EGR refined with a VVT valve |

| - | * [[Sunny_Truck_Electronic_Distributor#22100-95W10|Electronic Ignition]] to keep the tune longer (thus limiting emissions) | + | {{Main|EGR#1200}} |

| + | |||

| + | = {{Ref|R}} 1989 = | ||

| + | R - 昭和63 1988 regulations were applied to the late [[B122]] (R-B122) which arrived in 1989 October. | ||

| {{Album|25511}} | {{Album|25511}} | ||

| Line 144: | Line 186: | ||

| Buy at [http://www.datsun1200.asia/category/select/cid/427/pid/9334 Bprojects] | Buy at [http://www.datsun1200.asia/category/select/cid/427/pid/9334 Bprojects] | ||

| {{Album|26019}} | {{Album|26019}} | ||

| + | |||

| + | == 1200 Catalyst == | ||

| + | * NOx reduction via 3-way [[Catalytic Converter]]. A carburetor with mixture control ([[DFC306|ECU-controlled carb]] + [[Oxygen Sensor]]) is used to make the converter more efficient by keeping the mixture close to 14.7:1 | ||

| + | * Exhaust Temp warning lamp on dash 排気温度警告灯ランプ排気温度警告灯ランプ | ||

| + | * [[Sunny_Truck_Electronic_Distributor#22100-95W10|Electronic Ignition]] to keep the tune longer (thus limiting emissions) | ||

| Oxygen Sensor on the 95W [[Exhaust_Manifold#95W_Late_1200|Exhaust Manifold]] | Oxygen Sensor on the 95W [[Exhaust_Manifold#95W_Late_1200|Exhaust Manifold]] | ||

| <br>{{Photo|manifold-late.jpg|sightings/forum}} {{Photo|95W1.jpg}} | <br>{{Photo|manifold-late.jpg|sightings/forum}} {{Photo|95W1.jpg}} | ||

| + | |||

| + | Temp Sensor on converter [[Exhaust_Piping#Converter]] | ||

| + | <br>{{Album|27041}} {{Album|27181}} | ||

| Exhaust Temperature 'EXH TEMP' warning lamp on [[Dash#Late]] | Exhaust Temperature 'EXH TEMP' warning lamp on [[Dash#Late]] | ||

Current revision

度排出ガス規制適合

Note 保安基準適合 means Safety Standards.

Contents |

Overview

自動車排出ガス規制 automobile exhaust gas emissions regulations, the automobile of the internal combustion engine.

* 単体規制 Single Regulation (type regulation) applied to new models by the manufacturer * 車種規制 Vehicle Regulation constant regulation

1966 CO under 3% 1967 16-item inspection 1969 CO under 2.5% 1970 CO inspection 5.5% idling 1972 CO inspection 4.5% idling 1973 testing 1974 NOx 1975 April: NAPS (Nissan Anti-Pollution System) announced 1975 first sticker used

1976 sticker (Left: Used, Right: New with peeling cover)

排出ガス対策済 ステッカー, 排出ガス対策済, 般社団法人日本自動車工業会 (JAMA)

NVCC

The first to clear the U.S. Muskie Act of 1970 was Honda, with the CVCC engine, which was subsequently used in Honda's first-generation Civic.

Nissan developed a stratified-charge cylinder head (a la CVCC) in 1973-1974. It was reportedly 2.1 liters, and from a photo looked like it might be an L-series engine. However in the end they were able to meet 1975 emissions standards by using NAPS instead.

Engine expected to meet U.S.-Japan smog rules

TOKYO - Nissan Motor Co., manufacturer of the Datsun automobile, Wednesday announced development of a low-pollution engine expected to meet Japanese and American auto-emission standards... Outgoing Nissan president Katsuju Kawamata admitted his company's NVCC technology might conflict with Honda's CVCC process it terms of patent right. But he said he would conferwith Honda to settle disputes that might arise.

Phoenix Arizona Republic October 25, 1973 pg A-10

Nissan Drops Engine Plans

Nissan Motor Co, Tokyo, Japan, said it has decided to suspend a commercial production plan of its "NVCC" (Nissan vortex-controlled combustion) engine.

Des Moines Register August 1, 1975 pg 17

Press Release 1973/10/23: Nissan Motor develops low-emission engine prototypeᴳ

「NVCC」エンジンを開発

––排気ガス規制対策に対処して!––Nissan Motor Develops Low-Emission Engine Prototype

(10 . 24 . No.55)

日産自動車では、かねてから排気ガス規制対策のため、トーチ点火燃焼方式による新エンジン「NVCC」の開発研究を進めてきたが、実験室

段階では、ほぼ完成の域に達し、このほど運輸省交通安全公害研究所の要請により試験車を提出して、排気の測定実験を行なった。

その過程で得られた実験データーは次表の通りであり、国内五十年規制基準値および米国七十五年原規制値を充たす数値が得られた。

同社では、この結果に自信を深め将来、実用車とするために、さらに試作実験を重ねることを明らかにした。

...

1973

S48 (1973) 昭和48年

First applies to B210 1973- (not B110 1970-1972) * Sealed Fuel Tank with Flow Guide Valve for ventilation * Flow Control Valve 14920-H5000 (mounts on #1 intake runner) * Anti-diesel Valve (or Run-on Solenoid for A12T) * Idle compensator in Air Cleaner * Distributor D411-89

排出ガス対策済 Exhaust gas countermeasures completed 点火時期制御方式の排出ガス減少装置 anti-emissions devices of the ignition timing control system

H 1975

"H" is the 1975 (50年度) emission standards. Also in 1975 in the United States similar regulations came into effect. In Japan, compliance was met with NAPS, a combination of EGR and Catalyst to reduce NOx, CRANK to reduce combustion CO, and EVAPO with charcoal canister to reduce fuel evaporation HC emissions.

* H-B210 meets H-level emission standards

* H-B120 from 1975 uses NAPS-A engine A12

B210 EGR

All B211 (from December 1975) and VB210 (from October 1975) used EGR Exhaust Gas Reduction. This included Vans which were not fitted with catalytic converters.

B210 Catalyst

Nissan system's of exhaust gas cleaning by catalyzed oxidation (NAPS) adopted. A 2-way catalytic converter converted carbon monoxide (CO) and unburned hydrocarbons (HC) to produce "harmless" carbon dioxide (CO2) and water (H2O). It was only later than CO2 was acknowledged to be a pollutant itself. NOTE: In 1980 the 3-way converter introduced a 3rd reaction to reduce the third major pollutant NOx.

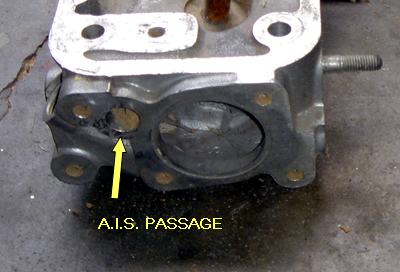

To enable efficient conversion, extra oxygen is introduced into the exhaust system by use of Nissan A.I.S. (Air Injection System), using a passive air induction (tuned pulse-flow) system. It used a cylinder head with an air passage drilled from front to back.

No feedback was used to control the fuel system. A carefully tuned carburetor was sufficient to meet the 1975 emissions target.

20905 CATALYST 20905-H7401 * JAPAN B211 A12.S,K 7512- * JAPAN HB211 A14.S,K 7512- * JAPAN GB211 L16 7602- (51 year standard) * not used on Van

Because the very hot converter is located under the passenger seat:

- a temperature warning system is fitted

- seat mounting is modified. 1976-1977 Passenger seat clears the bulge in the floor

Exhaust Temp warning lamp on dash 排気温度警告灯ランプ排気温度警告灯ランプ

Relay#25230-89915 floor sensor relay

Seat for converter-equipped B211

Unleaded Fuel

無鉛 Unleaded petrol only

B120 14807-89910 STICKER-FUEL 7510- * placed on assistant's window Buy at Bprojects無鉛 無鉛ガソリンを ご使用下さい

B120

14806-89901 LABEL-UNLEADED FUEL ONLY 8910-

* placed inside fuel door

触媒 無鉛に限る Catalyst - Limited to Unleaded

B 1976

1976 regulation including NOx

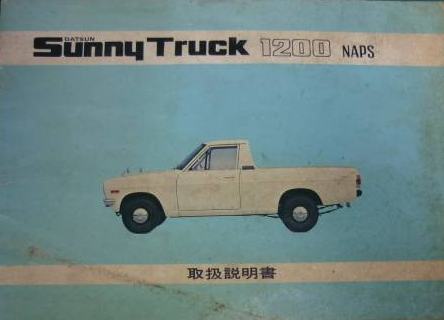

Applied to the 1200 October 1975

* Automatic Choke to reduce emissions during startup

E 1978

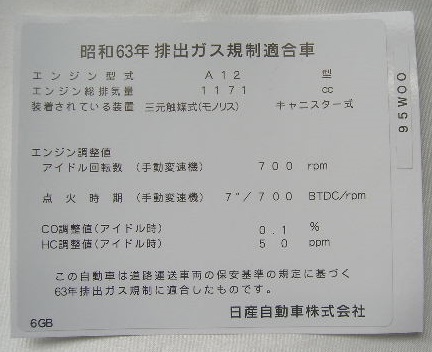

"E" 1978 emission standard (Showa 53 Year) 53年度排出ガス規制適合車

1200 Choke Warning

* Choke warning lamp added to Dash#Late April 1978 レエン、ワーニング ランプ (アート チヨーク レンズ) LENS-WARNING LAMP 24250-H2500 (Auto Choke Lens)

The dash 'Auto Choke' looks like a blank plate for the choke cable knob hole. Does it actually light up?

1200 EGR

* EGR comes to the 1200 for NOx reduction. See EGR#1200

L 1981

L - 1981 regulations was the reason for the B122 model change.

Spark Delay

1200 EGR with VVT

EGR refined with a VVT valve

R 1989

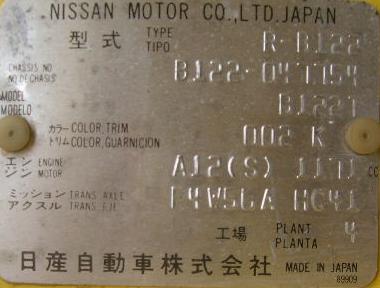

R - 昭和63 1988 regulations were applied to the late B122 (R-B122) which arrived in 1989 October.

14808-95W00 LABEL-EMISSION CONTROL,A 8910- * placed under bonnet Buy at Bprojects

1200 Catalyst

- NOx reduction via 3-way Catalytic Converter. A carburetor with mixture control (ECU-controlled carb + Oxygen Sensor) is used to make the converter more efficient by keeping the mixture close to 14.7:1

- Exhaust Temp warning lamp on dash 排気温度警告灯ランプ排気温度警告灯ランプ

- Electronic Ignition to keep the tune longer (thus limiting emissions)

Oxygen Sensor on the 95W Exhaust Manifold

Temp Sensor on converter Exhaust_Piping#Converter

Exhaust Temperature 'EXH TEMP' warning lamp on Dash#Late

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)