[< Previous 579 580 581 582 583 584 585 Next >]

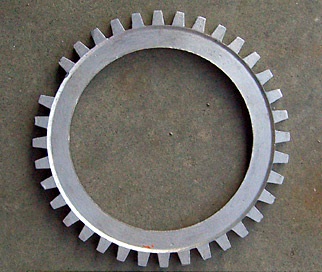

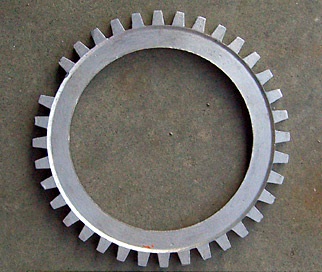

A series trigger wheel

lamb_daiquiri lamb_daiquiri  2014/8/6 9:32 2014/8/6 9:32  Tell a friend Tell a friend

3523 3523  8 8  0.00 (0 votes) 0.00 (0 votes)

| Made from the original A15 double pulley, the pulley's been turned down to 114mm diameter and the trigger wheel opened up. It's Epoxied on because the Ford trigger wheels are actually cast iron. |

|

|

[< Previous 579 580 581 582 583 584 585 Next >]

The comments are owned by the poster. We aren't responsible for their content.

| Poster |

Thread |

| ddgonzal |

Posted: 2016/1/6 1:45 Updated: 2016/1/6 2:19 |

Moderator   Joined: 2001/5/3 From: Kent, WA Posts: 31818 Online! |

Re: A series trigger wheel Looks like you started out with a late-model Aircon pulley? 129 mm (small) diameter Crank Pulley  ... and replaced the outer groove with the trigger wheel?  Looks like a Escort 1.9 SOHC trigger wheel |

|

|

|

| Poster |

Thread |

| lamb_daiquiri |

Posted: 2016/1/10 6:35 Updated: 2016/1/10 6:35 |

No life (a.k.a. DattoMaster)   Joined: 2009/4/30 From: Adelaide Posts: 1112 |

Re: A series trigger wheel That's the pulley that was on my A15, looked just like the picture you posted. The trigger wheel was off a ford in the wrecking yard, I don't know what sort, fwd 4 cylinder of some kind. The front groove came off when the trigger wheel went on.

|

|

|

|

|

| Poster |

Thread |

| ddgonzal |

Posted: 2016/1/10 7:14 Updated: 2016/1/10 7:16 |

Moderator   Joined: 2001/5/3 From: Kent, WA Posts: 31818 Online! |

Re: A series trigger wheel Yeah lots of EDIS parts on Aussie fords...did you get the 1992 Sierra

Btw, good job on the pulley, looks factory. Got any more pics of your setup?

|

|

|

|

| Poster |

Thread |

| clyons8 |

Posted: 2014/8/13 19:55 Updated: 2014/8/13 19:56 |

No life (a.k.a. DattoMaster)   Joined: 2007/1/22 From: East New Britain, Papua New Guinea Posts: 6981 |

Re: A series trigger wheel That has turned out very tidy Dylan.

My lathe is still out so I ended up welding the gear to the front of the pulley.

My plan for the proper item is to do what you did but go for an interference fit, freeze the pulley and heat the ring gear and press the two together with some adhesive.

|

|

|

|

| Poster |

Thread |

| lamb_daiquiri |

Posted: 2014/9/2 11:46 Updated: 2014/9/2 11:46 |

No life (a.k.a. DattoMaster)   Joined: 2009/4/30 From: Adelaide Posts: 1112 |

Re: A series trigger wheel Sorry, I didn't notice the comment.

I went for a sliding fit with adhesive because the trigger wheel is cast iron. Cast isn't very good in tensile loading so you run the risk of breaking it, particularly with the reduced section I ended up with. I guess that's why the OEM one had such a thick section there.

I didn't know it was cast to start with, a mate I work with (who used to be a fitter and turner, now engineer) did it for me. He started machining it and realised it was cast so stopped my original plan which was an interference fit like you say. That was when I thought it was some kind of steel.

I welded my prototype wheel, but heard it pinging as it cooled and wasn't game to try running it. Probably should've used nickel filler or pre and post heated.

|

|

|

|

|

| Poster |

Thread |

| ddgonzal |

Posted: 2014/9/11 20:23 Updated: 2014/9/11 20:23 |

Moderator   Joined: 2001/5/3 From: Kent, WA Posts: 31818 Online! |

Re: A series trigger wheel I opted to use neither expoxy nor interference fit. Since the trigger wheel has no load on it, it was simply bolted on. No problems over two years of running. It was bolted in front of the stock pulley using a longer crankshaft bolt.

|

|

|

|

|

| Poster |

Thread |

| lamb_daiquiri |

Posted: 2014/9/15 6:40 Updated: 2014/9/15 6:40 |

No life (a.k.a. DattoMaster)   Joined: 2009/4/30 From: Adelaide Posts: 1112 |

Re: A series trigger wheel Also a good option, I'm a little light on for space in front of the pulley.

|

|

|

|

|

| Poster |

Thread |

| thomen |

Posted: 2015/1/22 3:33 Updated: 2015/1/22 3:33 |

Home away from home   Joined: 2009/11/16 From: Sydney, NSW Posts: 615 |

Re: A series trigger wheel Looks awesome!

|

|

|

|

Mechanical

Mechanical Engine

Engine

0.00 (0 votes)

0.00 (0 votes)