I ran what was called a "light sports grind" cam in my GX many years ago & it idled just fine at about 850rpm. Performance was excellent for what was a commuter & a family hack with both good performance when I wanted it, & great economy when I drove it like an old fart. [which is what I am now.]

The original 1200 GX cam was not very 'hot' & a similar profile will work well in any GX configured engine.

OK, the A10 flywheel. It will bolt right up to the later cranks but they originally used a smaller diameter clutch with a smaller bolt circle doameter & even smaller bolts to hold them on.

Additionally they had a groove machined around the edge of the clutch disc which will lie underneath the larger/later clutches.

To use the A10 flywheel on a later engine it will be necessary to machine the whole face of the flywheel down to the depth of the groove & to redrill it so as to accept the later clutch.

While you are at it tou can clean up the back of the flywheel too.

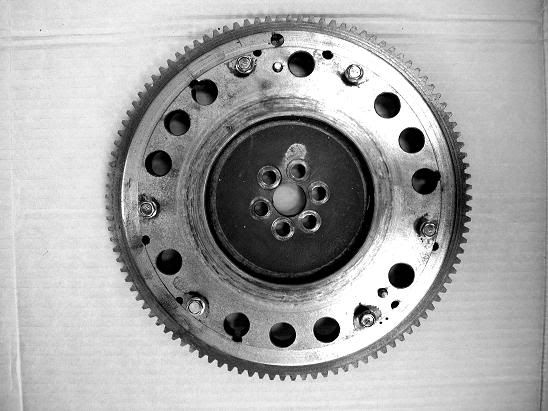

This is mine. I had it modified back in the early 80's & it weighs about 13 Lbs. I used it in my GX powered 1000 sedan for many years. [3.5mm or 0.140" overbored] It will likely end up behind the A13 for my KB10 after a good clean up, so yes, I still have it.

This is obviously the clutch side. Notice the ring of six smaller holes just outside the clutch disc marking. These originally were for the bolts that held the A10 clutch cover in place.

As always, click on image for a bigger picture.

This is the engine block side of the flywheel.

Again, you can see the ring of smaller diameter bolt holes along with the fact that it has been machined.

As can be seen, it doesn't take up a lot of room in the bellhousing.

One thing to note is the fact that the clutch will now sit a bit further forward & it may be necessary to use either the longer version of the release bearing carrier, or [as I did] use a spacer on the clutch cable adjustment to help bring the clutch fork far enough forward to gain satisfactory clutch function.

It's all too easy.

Transfer

Transfer