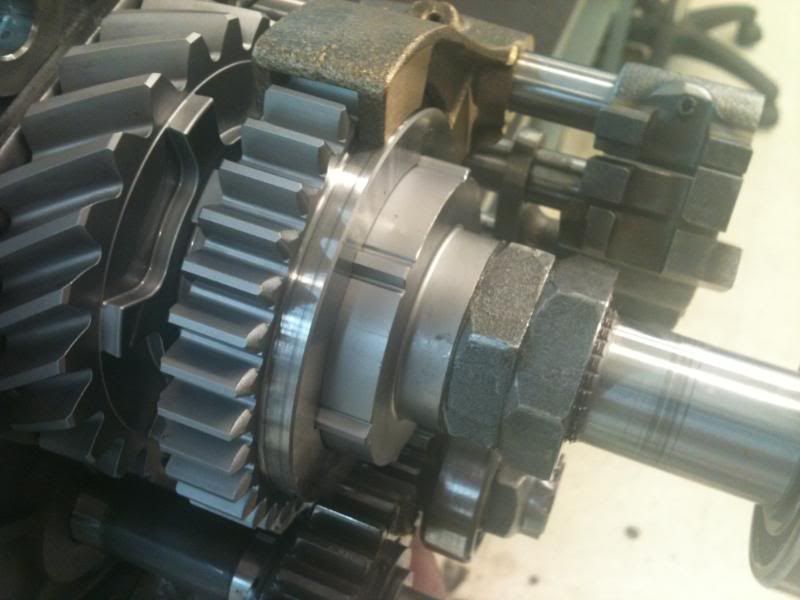

And this brings us roughly to our pornography shot. Unfortunately I didn't take pics of each individual bearings going on but as this gearbox came in with an alledged problem of slipping out of 5th we had to do a few tests to see if we could replicate it and we could not, so the box was pulled down again and locked up and then final assembly commenced. The reverse idler was fitted, mainshaft nut removed, all cleaned and primed and loktited with 263. New circlips for the bearings where applicable, bearings installed and layshaft nut also loktited and peened.

Heres a tip for installing ball bearings. In most cases they have a light interference fit of approximately 0.001", to avoid risking damaging the bearing by installing it with a hammer, get an old electric frying pan, set the temp to approx 160 deg C and warm the bearing up for 5 minutes then it will slip on and you will not have to touch a hammer.

At this stage I have also checked the selector rod and hub positions on all gears and tested the endfloat of all the gears to make sure that the mainshaft is in the correct position. The thrust washer on the back of 1st dog gear is also a shim which can be altered to get the averege position of the selector hubs set correctly.

Transfer

Transfer