Quote:

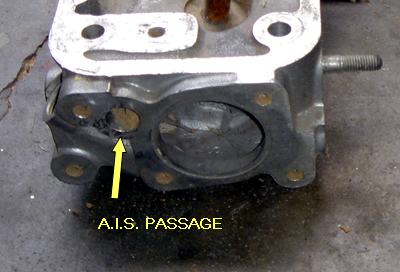

To reduce emissions without any power loss. A passive Air Injection system uses the engine exhaust pulses to draw fresh air into the port, thus continuing to burn more fully. Since no air pump is used there is no power loss

Quote:

How can i effectively port this to be efficient as possible? do i try and tig weld it shut or do i just normaly polish it.

Just port normally (clean up the bowl and inside radius, cut the guides down, use 7mm guides & valves). You can weld the holes shut if you want, how much difference it would make is unknown

For more power, weld up the combustion chambers into wedge chambers and use flat top pistons. With those open chambers use Premium fuel to reduce detonation problems, then you might as well boost the Compression Ratio and use a better chamber, which will work fine with Premium. Save fuel cost too as Premium is 10% more cost but the gain is 15% economy (along with more power)

Transfer

Transfer

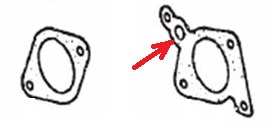

11041-H7763.jpg (36.06 KB)

11041-H7763.jpg (36.06 KB)