| Revision as of 07:19, 17 May 2015 ddgonzal (Talk | contribs) <- Previous diff |

Current revision ddgonzal (Talk | contribs) (->Ratio Adapter Box) |

||

| Line 7: | Line 7: | ||

| * 18/5 (4.11 diff) for Wagon or Ute | * 18/5 (4.11 diff) for Wagon or Ute | ||

| - | [http://datsun1200.com/modules/myalbum/photo.php?lid=15669 http://datsun1200.com/uploads/thumbs/15669.jpg] [http://i297.photobucket.com/albums/mm219/ddgonzal/Datsun%201200/wiki/19T.jpg http://i297.photobucket.com/albums/mm219/ddgonzal/Datsun%201200/wiki/th_19T.jpg] | + | Pinion | Pinion assembled into Sleeve |

| + | <br>{{Album|15669|width=SM}} {{PhotoH|19T.jpg|Datsun%201200/wiki|256}} | ||

| To adjust the speedometer for different diameter tires, change the transmission cable pinion cog. | To adjust the speedometer for different diameter tires, change the transmission cable pinion cog. | ||

| Line 16: | Line 17: | ||

| Given that stock is a 17 tooth pinion, moving to one more or less tooth is about 6% change. So by changing the pinion you can only get it to ±3 mph accurate. For example, at 100 mph, within 3 mph. Or at the standard 50 mph rating, a reading between 1½ mph (48½ to 51½) is the best you can hope for. For finer tuning the speedometer itself needs calibration. Or you could fit different diameter rear tires. | Given that stock is a 17 tooth pinion, moving to one more or less tooth is about 6% change. So by changing the pinion you can only get it to ±3 mph accurate. For example, at 100 mph, within 3 mph. Or at the standard 50 mph rating, a reading between 1½ mph (48½ to 51½) is the best you can hope for. For finer tuning the speedometer itself needs calibration. Or you could fit different diameter rear tires. | ||

| - | EXAMPLE: If you are reading say 60 when you are really going 50 then the speedo cable needs to slow down by about 20% to read more accurately. If the speedo drive has a 17 tooth cog in it try to find a cog that reduces by 20%. 17 X .20 = 3.4 teeth... 17 + 3.4 = 20.4 teeth, the closest is a 20 tooth cog.<table width=50% bordercolor=black border=1> | + | EXAMPLE: If you are reading say 60 when you are really going 50 then the speedo cable needs to slow down by about 20% to read more accurately. If the speedo drive has a 17 tooth cog in it try to find a cog that reduces by 20%. 17 X .20 = 3.4 teeth... 17 + 3.4 = 20.4 teeth, the closest is a 20 tooth cog.<table class="wiki_table"> |

| <tr bgcolor=ccccff><td>Teeth</td><td>% change</td><td>50 mph reading</td></tr> | <tr bgcolor=ccccff><td>Teeth</td><td>% change</td><td>50 mph reading</td></tr> | ||

| <tr><td>16</td><td>106.25%</td><td>53.1</td></tr> | <tr><td>16</td><td>106.25%</td><td>53.1</td></tr> | ||

| Line 23: | Line 24: | ||

| <tr><td>19</td><td>89.47%</td><td>44.7</td></tr></table> | <tr><td>19</td><td>89.47%</td><td>44.7</td></tr></table> | ||

| - | <br>Correction Table, increase Teeth by:<table border=1 cellspacing=0 width=100%> | + | <br>Correction Table, increase Teeth by:<table class="wiki_table"> |

| <tr bgcolor=ccccff><td> Actual mph</td><td> Desired mph</td><td> Tooth </td></tr> | <tr bgcolor=ccccff><td> Actual mph</td><td> Desired mph</td><td> Tooth </td></tr> | ||

| <tr><td> 40 </td><td> 50 </td><td> 3+ </td></tr> | <tr><td> 40 </td><td> 50 </td><td> 3+ </td></tr> | ||

| Line 31: | Line 32: | ||

| </table> | </table> | ||

| - | <br>Estimated Tire Correction Table (for 3.9 diff)<table border="1"> | + | <br>Estimated Tire Correction Table (for 3.9 diff)<table class="wiki_table"> |

| <tr bgcolor="ccccff"><td> Size </td><td> Diameter </td><td> Difference </td><td> Pinion </td><td> ~Error </td></tr> | <tr bgcolor="ccccff"><td> Size </td><td> Diameter </td><td> Difference </td><td> Pinion </td><td> ~Error </td></tr> | ||

| <tr><td> 165/55R12 </td><td> 19.1 </td><td> 88% </td><td> 19T </td><td> 0% </td></tr> | <tr><td> 165/55R12 </td><td> 19.1 </td><td> 88% </td><td> 19T </td><td> 0% </td></tr> | ||

| Line 43: | Line 44: | ||

| <tr><td> 185/60R15 </td><td> 23.7 </td><td> 109% </td><td> 16T/15T </td><td> 3% </td></tr> | <tr><td> 185/60R15 </td><td> 23.7 </td><td> 109% </td><td> 16T/15T </td><td> 3% </td></tr> | ||

| <tr><td> 205/40R18 </td><td> 24.5 </td><td> 112% </td><td> 15T </td><td> 0% </td></tr> | <tr><td> 205/40R18 </td><td> 24.5 </td><td> 112% </td><td> 15T </td><td> 0% </td></tr> | ||

| - | <table> | + | </table> |

| - | <br> | + | <br>Pinion & Sleeve assembled |

| + | <br>{{Photo|mwkjst5m_mot.jpg}} | ||

| + | |||

| = Part Numbers = | = Part Numbers = | ||

| + | 32702 Sleeve | ||

| + | 32703 Pinion gear | ||

| + | 32707 Sleeve Assembly (includes pinion) | ||

| + | |||

| + | Also see: [[Transmission Case Part Numbers]] | ||

| + | |||

| NOTE: while they are color-coded, order by part number, not by color. For example, 63-series and 56-series cogs (pinion gears) use different color coding. | NOTE: while they are color-coded, order by part number, not by color. For example, 63-series and 56-series cogs (pinion gears) use different color coding. | ||

| They are easy to replace by removing the roll pin...use your original Cog Body (Sleeve). | They are easy to replace by removing the roll pin...use your original Cog Body (Sleeve). | ||

| - | [http://datsun1200.com/modules/myalbum/photo.php?lid=19518 http://datsun1200.com/uploads/photos/19518.jpg] | + | {{Album|19518}} |

| + | |||

| + | 32707-18000 2-bolt style | ||

| + | <br>{{Photo|32707-18000.jpg}} | ||

| + | |||

| + | 32707-H1000 | ||

| + | Thread: M22 | ||

| + | Fix bolt hole: 7mm | ||

| + | I.D. (Pinion side): 9.3mm | ||

| + | I.D. (Thread Side):10mm | ||

| - | [http://i297.photobucket.com/albums/mm219/ddgonzal/Datsun%201200/wiki/32707-18000.jpg http://i297.photobucket.com/albums/mm219/ddgonzal/Datsun%201200/wiki/th_32707-18000.jpg] | + | 32707-H1000 1-bolt style |

| + | <br>{{Photo2|32707-H1000a.jpg}} {{Photo2|32707-H1000b.jpg}} {{Photo2|32707-H1000c.jpg}} {{Photo2|32707-H1000d.jpg}} | ||

| == 56 & 60 Series == | == 56 & 60 Series == | ||

| Line 61: | Line 80: | ||

| 32703-15400 PINION SPEEDOMETER 17T [White] $17.02 USD | 32703-15400 PINION SPEEDOMETER 17T [White] $17.02 USD | ||

| 32703-H1000 PINION SPEEDOMETER 18T [Blue] $15.67 USD | 32703-H1000 PINION SPEEDOMETER 18T [Blue] $15.67 USD | ||

| + | |||

| + | 15T | ||

| + | <br>{{Photo|32708-18001.jpg}} | ||

| SLEEVE W/PINION ASS'Y (3702) | SLEEVE W/PINION ASS'Y (3702) | ||

| Line 66: | Line 88: | ||

| 32702-H1000 ASSY-PINION SPEEDOMETER 18T (B120, 1975-1979) | 32702-H1000 ASSY-PINION SPEEDOMETER 18T (B120, 1975-1979) | ||

| 32702-H1001 ASSY-PINION SPEEDOMETER 19T (B120, 1980 up) | 32702-H1001 ASSY-PINION SPEEDOMETER 19T (B120, 1980 up) | ||

| + | |||

| + | 38425-18000 | ||

| + | <br>{{Photo|28425-18000.jpg}} | ||

| == Automatic Transmission == | == Automatic Transmission == | ||

| Line 125: | Line 150: | ||

| = Ratio Adapter Box = | = Ratio Adapter Box = | ||

| - | http://www.speedscreen.com.au/clarkbros.html | + | {{Main|Speedometer_Calibration#Cable Speed Correction}} |

| - | + | <br>{{Album!|26912}} | |

| - | http://www.speedscreen.com.au/Images/rbox.gif | + | |

| - | [[Category:Body Electrical System]] | + | [[Category:Body Electrical System]]{{End}} |

Current revision

The speedometer reading is adjustable via the various drive gears fitted at the transmission. Depending on which final gear ratio (differential gears) are fitted, the speedometer gears are changed to keep the speedometer accurate.

Contents |

Overview

Stock 1200 Speedometer gear ratio:

pinion teeth/worm teeth on trans output shaft * 17/5 (3.90 diff) * 18/5 (4.11 diff) for Wagon or Ute

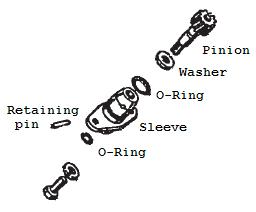

Pinion | Pinion assembled into Sleeve

To adjust the speedometer for different diameter tires, change the transmission cable pinion cog.

* If speedo reads too fast, fit a bigger cog * If speedo reads too slow, fit a smaller cog

Given that stock is a 17 tooth pinion, moving to one more or less tooth is about 6% change. So by changing the pinion you can only get it to ±3 mph accurate. For example, at 100 mph, within 3 mph. Or at the standard 50 mph rating, a reading between 1½ mph (48½ to 51½) is the best you can hope for. For finer tuning the speedometer itself needs calibration. Or you could fit different diameter rear tires.

EXAMPLE: If you are reading say 60 when you are really going 50 then the speedo cable needs to slow down by about 20% to read more accurately. If the speedo drive has a 17 tooth cog in it try to find a cog that reduces by 20%. 17 X .20 = 3.4 teeth... 17 + 3.4 = 20.4 teeth, the closest is a 20 tooth cog.| Teeth | % change | 50 mph reading |

| 16 | 106.25% | 53.1 |

| 17 | 100.00% | 50.0 |

| 18 | 94.44% | 47.2 |

| 19 | 89.47% | 44.7 |

Correction Table, increase Teeth by:

| Actual mph | Desired mph | Tooth |

| 40 | 50 | 3+ |

| 43 | 50 | 2+ |

| 47 | 50 | 1+ |

| 50 | 50 | 0+ |

Estimated Tire Correction Table (for 3.9 diff)

| Size | Diameter | Difference | Pinion | ~Error |

| 165/55R12 | 19.1 | 88% | 19T | 0% |

| 165/60R12 | 19.8 | 91% | 18T | -2% |

| 165/70R12 | 21.1 | 97% | 17T | 3% |

| 155/80R12 | 21.8 | 100% | 17T | 0% |

| 175/70R13 | 22.6 | 104% | 16T | 2% |

| 195/50R15 | 22.7 | 104% | 16T | 2% |

| 165/70R14 | 23.1 | 106% | 16T | 0% |

| 205/45R17 | 23.5 | 108% | 16T | -2% |

| 185/60R15 | 23.7 | 109% | 16T/15T | 3% |

| 205/40R18 | 24.5 | 112% | 15T | 0% |

Part Numbers

32702 Sleeve 32703 Pinion gear 32707 Sleeve Assembly (includes pinion)

Also see: Transmission Case Part Numbers

NOTE: while they are color-coded, order by part number, not by color. For example, 63-series and 56-series cogs (pinion gears) use different color coding.

They are easy to replace by removing the roll pin...use your original Cog Body (Sleeve).

32707-H1000 Thread: M22 Fix bolt hole: 7mm I.D. (Pinion side): 9.3mm I.D. (Thread Side):10mm

56 & 60 Series

56-Series Transmission and 60-Series Transmission

PINION (32703) 32703-18001 PINION ASSY-SPEEDOMETER (15T) 32703-18000 PINION ASSY-SPEEDOMETER (16T) $10.55 USD 32703-15400 PINION SPEEDOMETER 17T [White] $17.02 USD 32703-H1000 PINION SPEEDOMETER 18T [Blue] $15.67 USD

SLEEVE W/PINION ASS'Y (3702) 32702-15400 ASSY-PINION SPEEDOMETER 17T $17.02 USD 32702-H1000 ASSY-PINION SPEEDOMETER 18T (B120, 1975-1979) 32702-H1001 ASSY-PINION SPEEDOMETER 19T (B120, 1980 up)

Automatic Transmission

32703-P2616 PINION SPEEDOMETER 16T (auto) $23.22 USD 32703-P2617 PINION SPEEDOMETER 17T (auto) $12.78 USD 32703-P2618 PINION SPEEDOMETER 18T (auto) $23.43 USD 32703-P2619 PINION SPEEDOMETER 19T (auto) $12.78 USD 32703-P2620 PINION SPEEDOMETER 20T (auto) $12.83 USD 32703-P2621 PINION SPEEDOMETER 21T (auto) $21.12 USD 32702-P2719 ASSY-PINION SPEEDOMETER 19T (auto) $30.80 USD

63-Series

32703-N9016 PINION SPEEDOMETER 16T $13.28 USD 32703-N9017 PINION SPEEDOMETER 17T $12.42 USD 32703-N9018 PINION SPEEDOMETER 18T $12.42 USD 32703-N9019 PINION SPEEDOMETER 19T $11.80 USD

Application

56 & 60 Series

B110 with 3.90: 17T B110 with 4.11: 18T B210 with A13: 17T B210 with A13: 18T (optional Sedan) B210 with A14: 17T to 0376 B210 with A14: 16T from 0476 B310 with A12 North America: 17T B310 with A14/A15: 16T

FS5W63A

NOTE: 63 5-speed and 4-speed pinion gears have a different part numbers, so perhaps do not interchange.

32703-N9016 16T * JDM A10 F5 * USA B210 F5

32703-N9017 17T * USA S10 1977-1979 * USA D21 2WD F5 * USA GC22 1987-1989 Nissan Van [RS5W71C]

32703-N9018 18T * USA D21 F4 1988-1989 * USA D21 2WD F5 1986-1992 SELECT

32703-N9019 19T * USA D21 2WD F5 1986-1992 SELECT

Pinion or Assembly

Each drive gear (on the output shaft of the transmission) works with a variety of different pinion gears.

For the A-series gearboxes, there is only one size of drive gear, which works with 16-19 teeth pinions. The sleeves are all the same, so all you need is the gear (not the assembly).

Different transmission have different methods:

* Jeep - offset holder is rotated to various positions for each gear * GM TH350 - two drive gears, each works with a range of driven gears * Nissan 720: all have 6T drive gear * Nissan 56-series, 60: driven gear is machined on the shaft * Nissan 4W63, 71B, 71: replaceable gear

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)