| Revision as of 20:04, 8 August 2011 ddgonzal (Talk | contribs) (->Overview) <- Previous diff |

Current revision ddgonzal (Talk | contribs) (->Overview) |

||

| Line 5: | Line 5: | ||

| = Overview = | = Overview = | ||

| Find TDC | Find TDC | ||

| + | * degree wheel on crank pulley | ||

| * One dial indicator on piston head | * One dial indicator on piston head | ||

| ** Through spark plug hole | ** Through spark plug hole | ||

| ** or, directly if head is removed | ** or, directly if head is removed | ||

| - | [http://datsun1200.com/modules/myalbum/photo.php?lid=3639 http://datsun1200.com/modules/myalbum/photos/thumbs/3639.jpg] | + | {{Album|3639}} |

| - | <br>NOTE: You can also use a piston stop to find TDC | + | <br>NOTE: You can also use a piston stop to [[#find TDC]] |

| - | + | ||

| Advance crankshaft (turn clockwise) until lifter comes up 0.050": | Advance crankshaft (turn clockwise) until lifter comes up 0.050": | ||

| Line 18: | Line 18: | ||

| Note the degree at which 0.050 lift occurs | Note the degree at which 0.050 lift occurs | ||

| - | Continue turning and note maximum lift. | + | Continue turning and note maximum lift. Compare to the camshaft specification sheet that comes with your camshaft. Or to the factory specifications below. |

| Check each lobe the same way to see if any lobes are worn. | Check each lobe the same way to see if any lobes are worn. | ||

| + | |||

| + | = Find TDC = | ||

| + | * Turn the crank pulley to line up the timing cover "0" with the crank pulley mark. This is TDC. | ||

| + | |||

| + | OR | ||

| + | |||

| + | * Find true TDC using positive stopped piston | ||

| + | |||

| + | Use a {{search|14mm+piston+stop|14mm piston stop}} $16 USD (or you can make one). | ||

| + | <br>{{UploadPost|174_6103ddba1cda1.jpg|495656}} | ||

| + | # pull all plugs so you can easily turn engine by hand | ||

| + | # Put engine in approximate TDC, then rotate a bit further | ||

| + | # thread in the Stop to the #1 spark plug hole. Then turn the shaft in until it stops on the piston | ||

| + | # rotate back (by hand) a bit to be sure then engine stops (hits the Piston Stop) | ||

| + | # Mark the pulley | ||

| + | # rotate the opposite way (almost a full turn) until engine stops again | ||

| + | # Mark the pulley | ||

| + | Halfway between the two marks is TDC | ||

| = Fine Adjustments = | = Fine Adjustments = | ||

| Advance or retard the camshaft using: | Advance or retard the camshaft using: | ||

| - | * slotted key | + | * offset key for cam pulley |

| * or, adjustable cam pulley | * or, adjustable cam pulley | ||

| Line 32: | Line 50: | ||

| Retarding the cam moves the power band up in the RPM range | Retarding the cam moves the power band up in the RPM range | ||

| - | Advancing the cam lowers teh power band in the RPM range. | + | Advancing the cam lowers the power band in the RPM range. |

| Of course using the right camshaft is even better, but this technique can be used to see the effects: | Of course using the right camshaft is even better, but this technique can be used to see the effects: | ||

| Line 41: | Line 59: | ||

| Slotted cam pulley for adjustment | Slotted cam pulley for adjustment | ||

| <br>[http://datsun1200.com/modules/myalbum/photo.php?lid=3639 http://datsun1200.com/modules/myalbum/photos/thumbs/3639.jpg] | <br>[http://datsun1200.com/modules/myalbum/photo.php?lid=3639 http://datsun1200.com/modules/myalbum/photos/thumbs/3639.jpg] | ||

| + | |||

| + | Measuring lift | ||

| + | <br>[http://datsun1200.com/modules/myalbum/photo.php?lid=9528 http://datsun1200.com/uploads/thumbs/9528.jpg] | ||

| = Factory Specifications = | = Factory Specifications = | ||

| + | See [[Camshaft Comparison]] for more details. | ||

| + | |||

| 240/240 duration (A10 Datsun 1000) | 240/240 duration (A10 Datsun 1000) | ||

| - | 248/248 duration (standard small bore) | + | 248/248 duration (standard small bore A12/A13) |

| - | 248/256 duration (standard large bore) | + | 256/248 duration (standard large bore A14/A15) |

| - | 256/256 duration (performance engines) | + | 256/256 duration (performance engines GX/A12T/EGI) |

| - | 244/248 duration (Late USA emission) | + | 248/244 duration (1981-1982 USA) |

| + | 248/248 as used by standard A12 | ||

| + | <br>[http://datsun1200.com/modules/myalbum/photo.php?lid=23656 http://datsun1200.com/uploads/photos/23656.jpg] | ||

| + | <br>248/248/14/54/12/56 | ||

| + | Late-model | ||

| + | <br>[http://datsun1200.com/modules/myalbum/photo.php?lid=18422 http://datsun1200.com/uploads/photos/18422.jpg] | ||

| + | <br>248/244/14/50/12/56 | ||

| + | <br>248/248/14/54/12/56 | ||

| + | <br>248/244/14/50/12/56 | ||

| + | <br>256/248/14/54/20/56 | ||

| - | A12 from 1970 to 1980s -- same spec | + | B310 Australia? |

| - | * A12: 248/248 | + | <br>[http://datsun1200.com/modules/myalbum/photo.php?lid=6195 http://datsun1200.com/modules/myalbum/photos/6195.jpg] |

| - | * 13001-H1000 for old-style blocks | + | <br>A14: 256/248 |

| - | ** 13001-H7000 for USA 1973 | + | <br>A12: 248/248 |

| - | * 13001-H5000 for revised blocks | + | |

| + | = Aftermarket Specifications = | ||

| + | 210/199 Camtech "turbo" profile 600A68A-TURBO | ||

| + | <br>246/239/14/52/4/55 | ||

| + | <br>[http://datsun1200.com/modules/myalbum/photo.php?lid=921 http://datsun1200.com/uploads/thumbs/921.jpg] | ||

| - | See [[Camshaft Comparison]] for more details. | + | <br>228/228 Iskenderian D8-66 |

| + | <br>228/228/5/43/6/43 | ||

| + | <br>266/256/24/62/24/62 | ||

| + | <br>[http://datsun1200.com/modules/myalbum/photo.php?lid=7518 http://datsun1200.com/uploads/thumbs/7518.jpg] | ||

| + | 274/271 JTS 104CB | ||

| + | <br>212/212/-2/35/-5/37 | ||

| + | <br>[http://datsun1200.com/modules/myalbum/photo.php?lid=14441 http://datsun1200.com/uploads/thumbs/14441.jpg] | ||

| - | B310 Australia? | + | 291/296 JTS 140-6 |

| - | <br>[http://datsun1200.com/modules/myalbum/photo.php?lid=6195 http://datsun1200.com/modules/myalbum/photos/thumbs/6195.jpg] | + | <br>238/238/15/42/10/47 |

| - | A14: 256/248 | + | <br>[http://datsun1200.com/modules/myalbum/photo.php?lid=15607 http://datsun1200.com/uploads/thumbs/15607.jpg] |

| - | A12: 248/248 | + | |

| + | Smiths Regrinds (Mace Engineering) | ||

| + | <br>0.050 specs not listed | ||

| + | <br>[http://datsun1200.com/modules/myalbum/photo.php?lid=7041 http://datsun1200.com/uploads/thumbs/7041.jpg] | ||

| + | |||

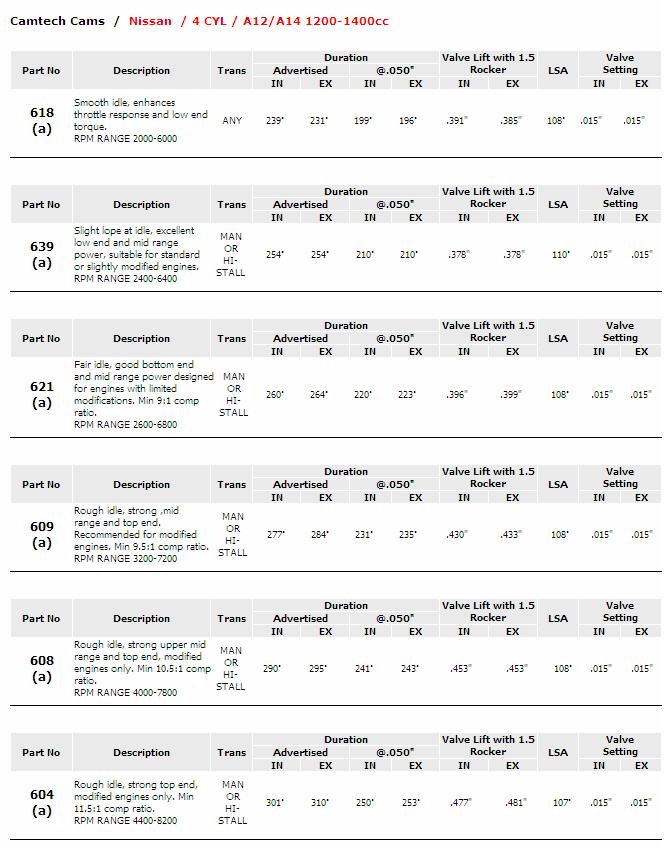

| + | Camtech Cams | ||

| + | <br>618: 199/196 2000-6000 RPM | ||

| + | <br>639: 210/210 2400-6400 RPM | ||

| + | <br>621: 220/223 2600-6800 RPM | ||

| + | <br>609: 231/235 3200-7200 RPM | ||

| + | <br>608: 241/243 4000-7000 RPM | ||

| + | <br>604: 250/253 4400-8200 RPM | ||

| + | <br>[http://datsun1200.com/modules/myalbum/photo.php?lid=23657 http://datsun1200.com/uploads/photos/23657.jpg] | ||

| + | |||

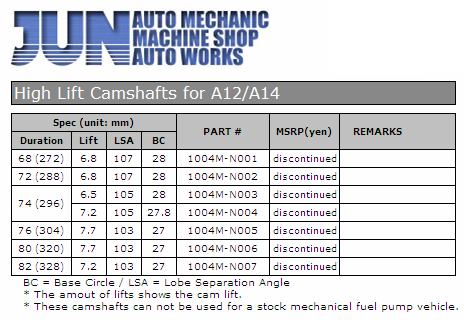

| + | JUN Camshafts | ||

| + | <br>68, 72, 74, 76, 80, 82 | ||

| + | <br>[http://datsun1200.com/modules/myalbum/photo.php?lid=23658 http://datsun1200.com/uploads/photos/23658.jpg] | ||

| + | |||

| + | 74 [[Bprojects]] RACING CAMSHAFT 296-7.0 | ||

| + | Usage: new-style A12 | ||

| + | Duration: 74 (296) | ||

| + | Cam Lift: 7.0mm (0.276") | ||

| + | Cold Valve Clearance: 0.3mm (0.012") | ||

| + | Valve Timing Centerline: 103.5(Deg) | ||

| + | Wavy groove finish and Surface Coating | ||

| + | *TOMEI Ouality Control | ||

| + | |||

| + | [http://datsun1200.com/modules/myalbum/photo.php?lid=23659 Auckland Cams] | ||

| + | <br><img size=560>http://datsun1200.com/uploads/photos/23659.jpg</img> | ||

| + | |||

| + | |||

| + | grind #A057 Auckland Cams | ||

| + | Type: Fast Road | ||

| + | IN Advertised duration: 280 degrees | ||

| + | EX Advertised duration: 280 degrees | ||

| + | IN Duration at .050": 233 degrees | ||

| + | IN Duration at .050": 233 degrees | ||

| + | IN Cam lift:.284" | ||

| + | EX Cam lift .284" | ||

| + | Lobe separation: 108.5 degrees | ||

| + | This cam will have a lopey idle and is suitable for high performance street use and/or rally applications. Wide power band 2200-7000 rpm. Can be used with stock standard engine and will run well. For best results use with of 10.0 to 1 compression ratio, twin carbs and extractors. | ||

| + | |||

| + | = Conversion = | ||

| + | Japan to non-Japan duration | ||

| + | |||

| + | 68 272 | ||

| + | 70 | ||

| + | 72 288 | ||

| + | 74 296 | ||

| + | 76 304 | ||

| + | 80 320 | ||

| + | 82 328 | ||

| + | |||

| + | = Valve Lift = | ||

| + | Each manufacturer specifies this differently. The spec is valve lift (at the valve) but the cam lobe lift is amplified by the rocker arm ratio less valve lash: | ||

| + | Nissan: 1.44 ratio, cam lift not specified | ||

| + | JTS: 1.5 ratio, but they also specify cam lift | ||

| + | Camtech: cam lift only specified | ||

| + | Isky: ~1.48 ratio | ||

| + | |||

| + | For example: | ||

| + | Nissan cam lobe in.: 1.426" std (wear limit: 1.4055") | ||

| + | Nissan cam lobe in.: 1.187" base circle | ||

| + | Nissan cam lift: ~0.239" | ||

| + | Nissan Lash: ~0.013" | ||

| + | Nissan ratio: 1.44 | ||

| + | Nissan valve lift: 0.331" | ||

| + | |||

| + | = Valve Lash = | ||

| + | Aftermarket camshaft grinders recommend from 0.010" to 0.024" depending on the profile (standard lash is 0.013" warm/0.014" cold). | ||

| + | |||

| + | [[Category:Valvetrain]] | ||

Current revision

Checking and adjusting the camshaft timing is an important part of a competition engine. You can also do the same for your street 1200 to ensure you are getting the expected performance.

Also see Camshaft Comparison

Contents |

Overview

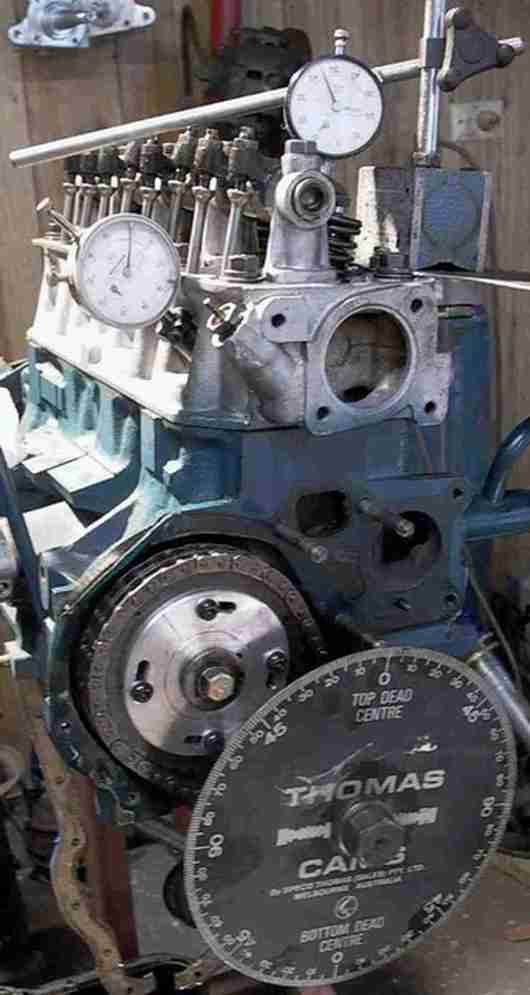

Find TDC

- degree wheel on crank pulley

- One dial indicator on piston head

- Through spark plug hole

- or, directly if head is removed

NOTE: You can also use a piston stop to #find TDC

Advance crankshaft (turn clockwise) until lifter comes up 0.050":

- Second dial indicator on pushrod, to measure cam lift

- Timing wheel to have 360 degree measurement

Note the degree at which 0.050 lift occurs

Continue turning and note maximum lift. Compare to the camshaft specification sheet that comes with your camshaft. Or to the factory specifications below.

Check each lobe the same way to see if any lobes are worn.

Find TDC

- Turn the crank pulley to line up the timing cover "0" with the crank pulley mark. This is TDC.

OR

- Find true TDC using positive stopped piston

Use a 14mm piston stopᴳ $16 USD (or you can make one).

- pull all plugs so you can easily turn engine by hand

- Put engine in approximate TDC, then rotate a bit further

- thread in the Stop to the #1 spark plug hole. Then turn the shaft in until it stops on the piston

- rotate back (by hand) a bit to be sure then engine stops (hits the Piston Stop)

- Mark the pulley

- rotate the opposite way (almost a full turn) until engine stops again

- Mark the pulley

Halfway between the two marks is TDC

Fine Adjustments

Advance or retard the camshaft using:

- offset key for cam pulley

- or, adjustable cam pulley

Modified timing cover to suit adjustable cam gear

Retarding the cam moves the power band up in the RPM range

Advancing the cam lowers the power band in the RPM range.

Of course using the right camshaft is even better, but this technique can be used to see the effects:

- fine tune the cam to the engine

- fine tune the cam/engine to each particular track

- cover up a mis-matched cam

Slotted cam pulley for adjustment

Factory Specifications

See Camshaft Comparison for more details.

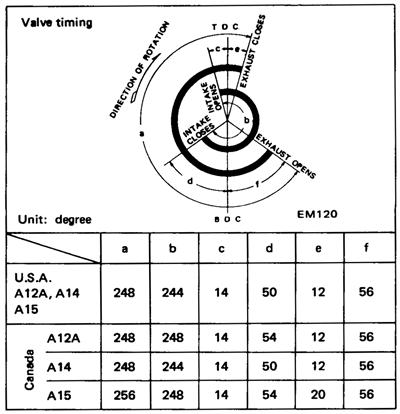

240/240 duration (A10 Datsun 1000) 248/248 duration (standard small bore A12/A13) 256/248 duration (standard large bore A14/A15) 256/256 duration (performance engines GX/A12T/EGI) 248/244 duration (1981-1982 USA)

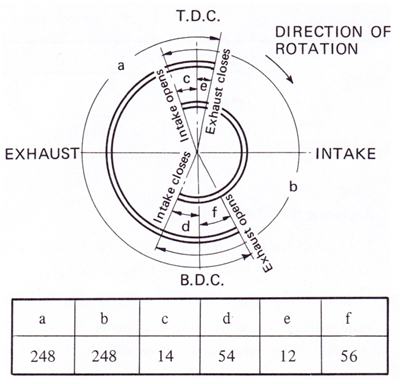

248/248 as used by standard A12

248/248/14/54/12/56

Late-model

248/244/14/50/12/56

248/248/14/54/12/56

248/244/14/50/12/56

256/248/14/54/20/56

B310 Australia?

A14: 256/248

A12: 248/248

Aftermarket Specifications

210/199 Camtech "turbo" profile 600A68A-TURBO

246/239/14/52/4/55

228/228 Iskenderian D8-66

228/228/5/43/6/43

266/256/24/62/24/62

274/271 JTS 104CB

212/212/-2/35/-5/37

291/296 JTS 140-6

238/238/15/42/10/47

Smiths Regrinds (Mace Engineering)

0.050 specs not listed

Camtech Cams

618: 199/196 2000-6000 RPM

639: 210/210 2400-6400 RPM

621: 220/223 2600-6800 RPM

609: 231/235 3200-7200 RPM

608: 241/243 4000-7000 RPM

604: 250/253 4400-8200 RPM

JUN Camshafts

68, 72, 74, 76, 80, 82

74 Bprojects RACING CAMSHAFT 296-7.0

Usage: new-style A12 Duration: 74 (296) Cam Lift: 7.0mm (0.276") Cold Valve Clearance: 0.3mm (0.012") Valve Timing Centerline: 103.5(Deg) Wavy groove finish and Surface Coating *TOMEI Ouality Control

grind #A057 Auckland Cams

Type: Fast Road IN Advertised duration: 280 degrees EX Advertised duration: 280 degrees IN Duration at .050": 233 degrees IN Duration at .050": 233 degrees IN Cam lift:.284" EX Cam lift .284" Lobe separation: 108.5 degrees

This cam will have a lopey idle and is suitable for high performance street use and/or rally applications. Wide power band 2200-7000 rpm. Can be used with stock standard engine and will run well. For best results use with of 10.0 to 1 compression ratio, twin carbs and extractors.

Conversion

Japan to non-Japan duration

68 272 70 72 288 74 296 76 304 80 320 82 328

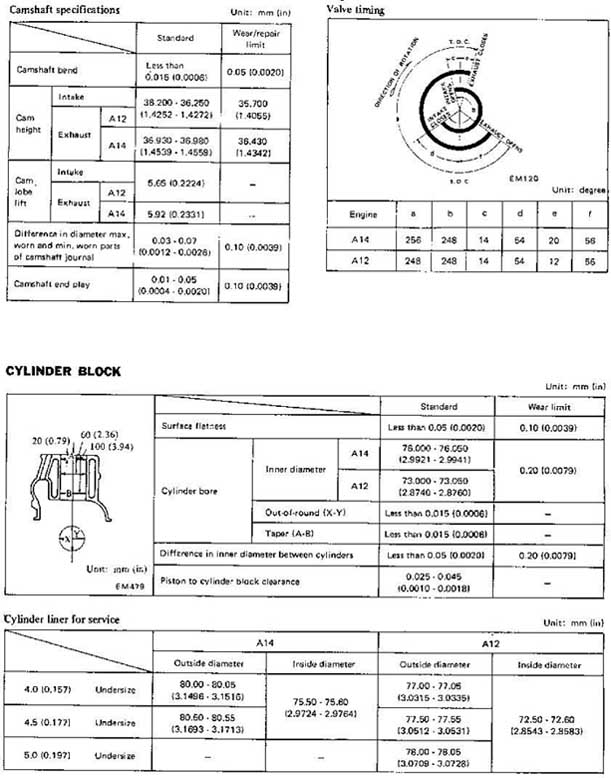

Valve Lift

Each manufacturer specifies this differently. The spec is valve lift (at the valve) but the cam lobe lift is amplified by the rocker arm ratio less valve lash:

Nissan: 1.44 ratio, cam lift not specified JTS: 1.5 ratio, but they also specify cam lift Camtech: cam lift only specified Isky: ~1.48 ratio

For example:

Nissan cam lobe in.: 1.426" std (wear limit: 1.4055") Nissan cam lobe in.: 1.187" base circle Nissan cam lift: ~0.239" Nissan Lash: ~0.013" Nissan ratio: 1.44 Nissan valve lift: 0.331"

Valve Lash

Aftermarket camshaft grinders recommend from 0.010" to 0.024" depending on the profile (standard lash is 0.013" warm/0.014" cold).

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)