| Revision as of 00:14, 31 December 2006 Ddgonzal (Talk | contribs) <- Previous diff |

Revision as of 06:18, 31 August 2017 ddgonzal (Talk | contribs) Next diff -> |

||

| Line 1: | Line 1: | ||

| - | Ideal rocker geometry when calculating pushrod length with roller rockers. | + | Ideal rocker geometry when calculating pushrod length with roller rockers. |

| - | [http://datsun1200.com/modules/myalbum/photo.php?lid=4355 http://datsun1200.com/modules/myalbum/photos/thumbs/4355.jpg] | + | {{Album|4355}} |

| - | + | ||

| - | When the head is excessively milled or when using custom valvetrain parts like [[Roller rockers]], fitting these requires precise measurement and assembly. Custom-length [[Pushrods]] will undoubtedly be required or you'll end up with an engine that goes bad or makes excessive noise and won't rev any higher. | + | |

| + | When the head is excessively milled or when using custom valvetrain parts like [[Roller rockers]], fitting these requires precise measurement and assembly. Custom-length [[Pushrods]] will undoubtedly be required or you'll end up with an engine that goes bad or makes excessive noise and won't rev any higher. | ||

| The theory for obtaining a length for the pushrod when using non-stock valvetrain parts is demonstrated in this picture, you will see on the bottom drawing that the cam is rotated to half lift and an imaginary line is drawn from the tip of the valve through the centre of the rocker shaft and picks up on the top of the pushrod, the reason for setting up on half lift is so that the rocker moves equal distances ie, in this case 45 deg to full lift and 45 deg to no lift which is optimum in a perfect world. This basic formula is what drag racing engine builders try to achieve, some times its not possible to get the "45-90-135" angles, some where close is good enough depending on each motor, having the angles way out can have nasty affects, i.e. bending pushrods, excessive wear on the pivots on the rockers. | The theory for obtaining a length for the pushrod when using non-stock valvetrain parts is demonstrated in this picture, you will see on the bottom drawing that the cam is rotated to half lift and an imaginary line is drawn from the tip of the valve through the centre of the rocker shaft and picks up on the top of the pushrod, the reason for setting up on half lift is so that the rocker moves equal distances ie, in this case 45 deg to full lift and 45 deg to no lift which is optimum in a perfect world. This basic formula is what drag racing engine builders try to achieve, some times its not possible to get the "45-90-135" angles, some where close is good enough depending on each motor, having the angles way out can have nasty affects, i.e. bending pushrods, excessive wear on the pivots on the rockers. | ||

| [[Category:Engine Mechanical]] | [[Category:Engine Mechanical]] | ||

| - | [[Category:Engine Modifications]] | + | [[Category:Engine Modifications]]{{End}} |

Revision as of 06:18, 31 August 2017

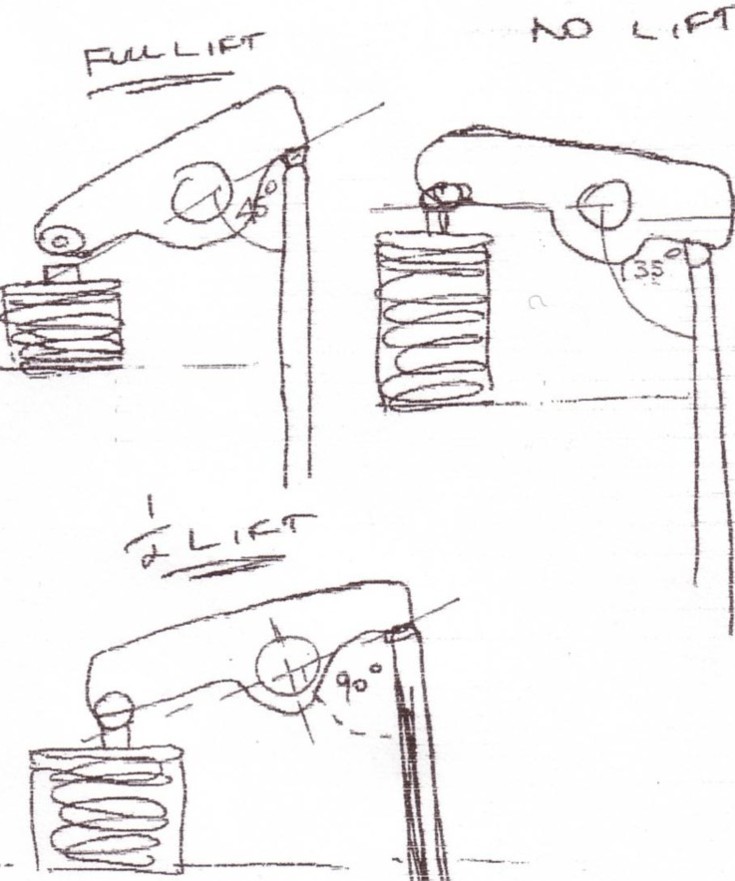

Ideal rocker geometry when calculating pushrod length with roller rockers.

When the head is excessively milled or when using custom valvetrain parts like Roller rockers, fitting these requires precise measurement and assembly. Custom-length Pushrods will undoubtedly be required or you'll end up with an engine that goes bad or makes excessive noise and won't rev any higher.

The theory for obtaining a length for the pushrod when using non-stock valvetrain parts is demonstrated in this picture, you will see on the bottom drawing that the cam is rotated to half lift and an imaginary line is drawn from the tip of the valve through the centre of the rocker shaft and picks up on the top of the pushrod, the reason for setting up on half lift is so that the rocker moves equal distances ie, in this case 45 deg to full lift and 45 deg to no lift which is optimum in a perfect world. This basic formula is what drag racing engine builders try to achieve, some times its not possible to get the "45-90-135" angles, some where close is good enough depending on each motor, having the angles way out can have nasty affects, i.e. bending pushrods, excessive wear on the pivots on the rockers.

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)