It's been a while since the last post, but here's my "guess."

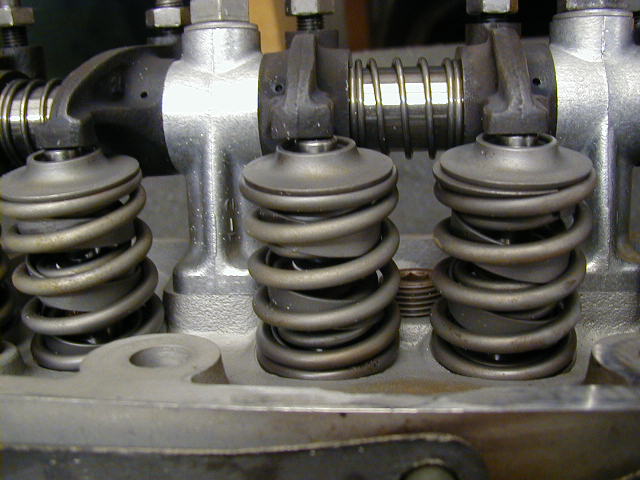

All springs all have a "harmonic" & at a certain number of openings per second the harmonic wave will end up working agains the spring, & it will not be able to do it's job. This means that the valve may not close at all, & i presume it will make passionate love with the piston.

When that happens, the engine's ummmm,.. no longer virginal.

A second spring, with a diferent harmonic rate will not only give some more seat pressure [if required] but will continue to pull the valve shut, even if the other one goes slack on the job.

As for three? I guess that it must be for an engine thats just coming on the cam at about 10,000 rpm. Would that be right dimlight65?

Hey,.. I'm impressed

P.S.

Johnno's garage says, Don't bother with all that dismantling & fitting shims business, just warm the rocker arm with a gas torch, & using a cresent wrench, just bend it to suit.

Squirt some oil on it while still hot to re-temper the metal & she'll be right.

Mechanical

Mechanical Engine

Engine

0.00 (0 votes)

0.00 (0 votes)