I'm in the same boat. I thought it was just me, but in addition to the rail breaking (same place) the rear seat mount has ripped away from the sill, and also cracked/torn the chassis rail. As I said, i thought it was just me, but I've now seen it on a few more coupes. The problem is, with the seat back a fair way (all the way back) the front floorpan bracket (which goes all the way from the sill to the trans hump, much stronger) bears almost zero weight, and it's ALL on the rear ones.

I've repaired the floor pan and bracket, but really it is just going to happen again.

I'm not as tall as you, but my head rubs on the roof lining over bumps, and I desperately need more leg room.

If I just altered the brackets, to move the seat further back, it would stress the 'weak' rear bracket even more.

So the option I've started on is to make custom rail/brackets, that span from that front seat mount bracket (the one that goes all the way across) then running 2 solid RHS beams back from there, all the way back to the crossmember in front of the diff (the one that is directly under the front edge of the rear seat. that crossmember area is MUCH stronger. So by making brackets that go there, and bear the bulk of the weight, it won't re-crack the floorpan in that other area.

It means I can mount the seat back further. the 'support beams' would 'usually' compromise the drivers side rear passenger leg room, but by the time I've moved the seat back where I want it, there's no gap behind the front seat backrest, so nobody could sit there anyway.

I'm going to mount the seat direct to these rails as well. Done carefully, this will mean the original sliding rails are gone. That isn't a big deal, as nobody else needs to drive it. By getting rid of the slide/rails, it lowers the 'bucket' part of the seat (if done 'right' by as much as 1-1.5 inches. SO no only more leg room but also more head room. Due to the angle of the fore/aft rails, the further back the seat is the lower it is. So I might just manage a full 2 inches extra headroom too - but I'll take absolutely all I can get.

The way I'm making this whole 'structure' it will bolt to the front factory rail via the front 2 bolts, but the rear rail will use angle iron to 'sit' on top of that rear crossmember. To give it wider support, I've cut some angle iron, then curved it, and welded a new piece in, so that it can go across the width of the rear crossmember, and slightly up and over the trans tunnel hump section.

If I choose the width right, it will 'sit' on there and wedge itself in, and be quite sturdy without bolts on the rear half. It'll make more sense when it is finished.

I should also warn anyone else trying to do this themselves of a tiny 'trap' you might fall in. don't just make the brackets and the rails 'square' with one another. The problem is the the rear crossmember isn't perfectly parallel. It narrows (which means it travels backward as it travels to the outside of the car). So if you cut the front to rear steel to identical lengths and welded it up, the rear bracket wouldn't sit flush, it'd be hanging forward about 5-10mm off the front of the outside edge of the crossmember.

SO basically you need to make the bits of angle iron first, and then measure the different lengths for the front to rear beams, tack, then weld them to another piece of angle iron, get it all fitting snug, and then welding it to the front angle iron bracket.

This is very early days for mine, and ideally it would have needed bigger angle iron, but I had a lot of 50mmx50mm angle iron spare, so I started with that. I will add a piece to the vertical wall of the rear one, so the front to rear beams can sit low enough.

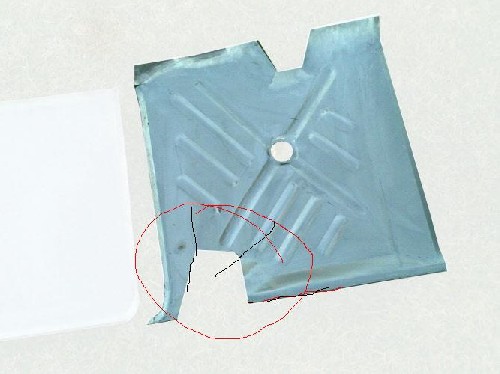

Anyway, here is the starting point:

it will require that I grind off the driver's side back seat securing bracket off of that rear crossmember/brace/chassis thing, so it can fit snug, but apart from that minor change, it is (once finished) a bolt in option, so that if somebody wanted to, down the track, they could unbolt this thing and bolt a seat with factory rails back in the original position.

I've started with a piece of angle iron for the front bracket

I have no doubt my ridiculous weight (more like Johnny Vegas than Arnold Schwarzeneggar) didn't help it, but they seem to be a weak link, and the floorpan itself isn't perhaps as thick as we might optimally like. I'd also add that the pics I used for the stripped out shell were not mine, I got them off this forum photo section originally, but used them as they were convenient to do a few ms paint edits on to make it clearer, and certainly quicker/easier than taking a lot of new pics and scanning them etc.

Transfer

Transfer

Rear Floor pan.jpg (33.43 KB)

Rear Floor pan.jpg (33.43 KB)