Awesome work Bede, can't wait to see this progress (I for certain will be wanting one...)

My 2cents:

Ports: Change the short turn shape. You want an elliptical short turn on the intake (ever increasing radius until it reaches the seat) and a rounder short turn on the exhaust. Short turn is where you will get the flow from the head - you want that flow sticking to it as it flows down and over the valve. As soon as the flow separates from the short turn it skips over the inside of the valve and you'll loose potential flow. The other way you can stop this separation from happening is to widen the short turn - D shaped with the floor more flat.

You want the smallest cross sectional area of the port to be back up off the valve in a N/A motor. This choke is spec'd to the engine (revs & capacity) so make sure you have plenty of meat there to be able to port to whats necessary.

Let me know when you want some more in depth specs regarding choke/throat sizing.

I reckon ditch the GA16de stuff - run billet cams (easy to make, and we can grind them for you), and use the largest buckets you can - motorbike maybe? 32mm would suffice. 27mm GA buckets are just too small to make some nice low duration cams with high lift for road motors. Other good thing about running large buckets is it opens up spring options.

Definitely do not run a slave gear like the Toyota 1uz / 4afe stuff. These things suck to time in and means you need to make an adjustable gear setup if you want to change your lobe separation. I'd also run a modern fine pitch chain rather than a belt - look at motorbikes for nice compact sprockets.

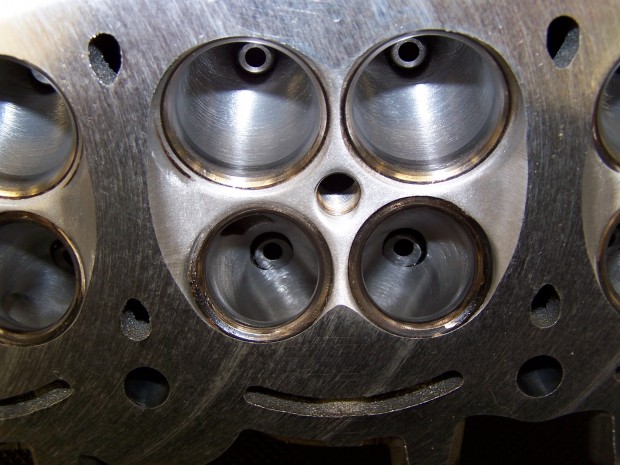

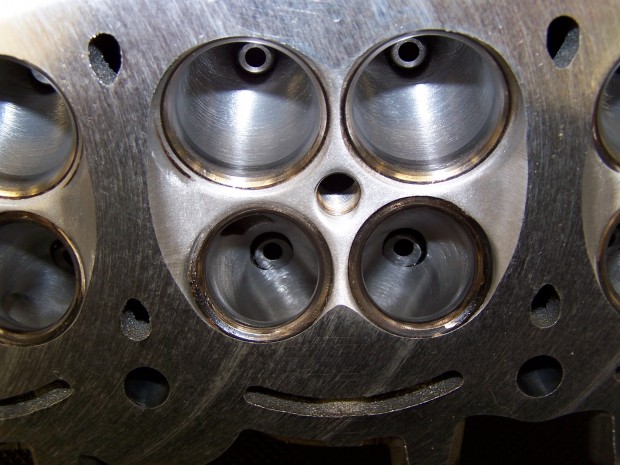

Chamber: Do a closed chamber with some mean squish. Like this

Transfer

Transfer

sani1.jpg (139.28 KB)

sani1.jpg (139.28 KB)