Here is the Build thread that goes with the discussion thread. It might be best not to post in this one, to keep it easy for others to read.

The discussion thread

http://datsun1200.com/modules/newbb/v ... e=&topic_id=64613&forum=1I thought some of you might be interested in how to build a cost effective EFI turbo setup that is upgradeable in the future.

I'll endevour to stay out of the machine shop and away from the TIG.

Most of it will be done with hand tools to keep it acheivable.

You will still need acess to a few tools:

-Mig welder

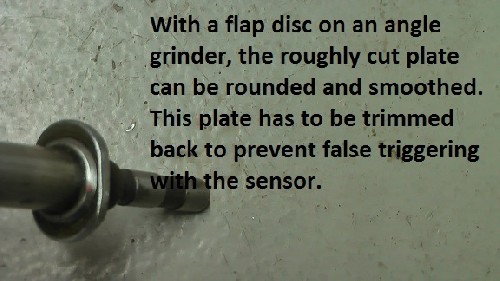

-Angle grinder with thin cutting wheels and flap discs.

-Drill and drill press

-Compressor and die grinder( or lots of patience and a file!!)

-Vice and vise grips/clamps

-Marking pen and masking tape(aluminium tape is even better)

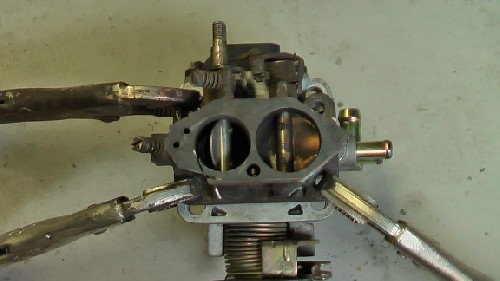

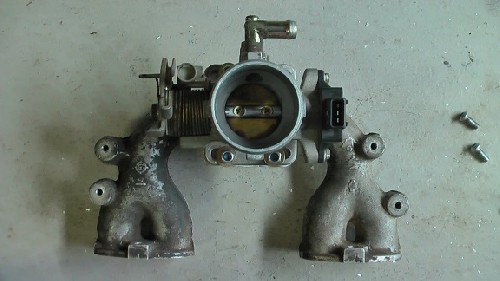

The basic initial setup uses the standard A12 inlet manifold fitted with a single Throttle body and 1 injector. The ECU is a Microsquirt V3. This allows for adding multiple coils and injectors later if required as well as boost control. Turbo is a single turbo from a twin turbo Nissan Skyline(there are plenty of Upgrade options if you want more power later on).

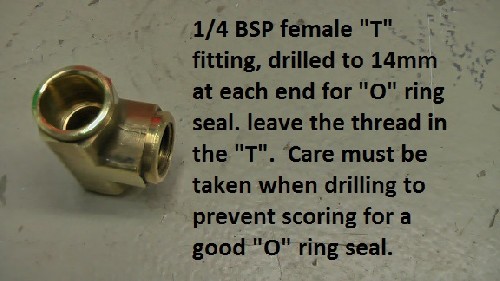

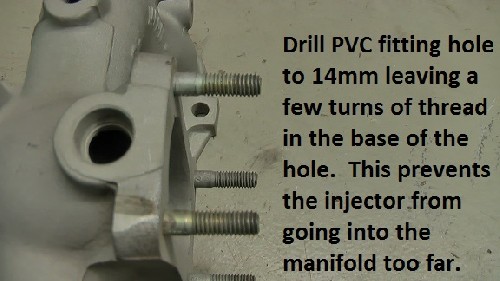

You will these bits for the inlet manifold:

-Throttle body from a X3 SOHC Hyundai Exel

-Fuel Pressure reg. from a 1997ish Misubishi Lancer or Toyota Corolla

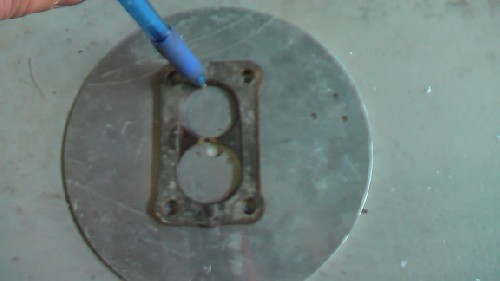

-3-5MM ally plate for the adaptor.

-1x Fuel injector(1000cc for petrol 1300+cc for E85)

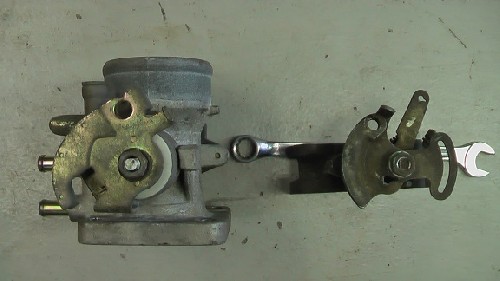

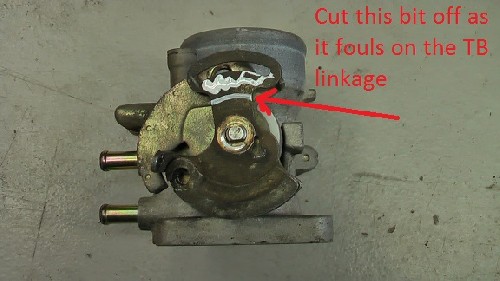

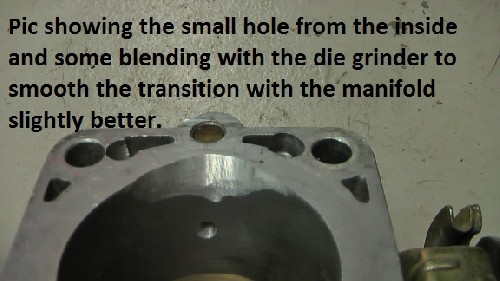

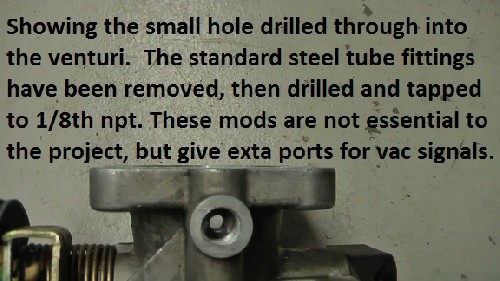

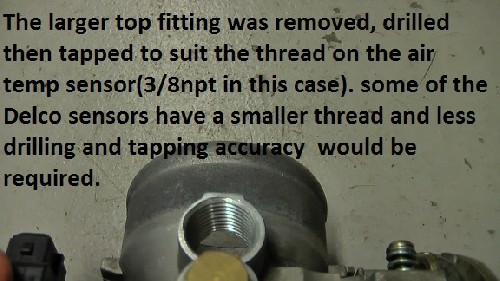

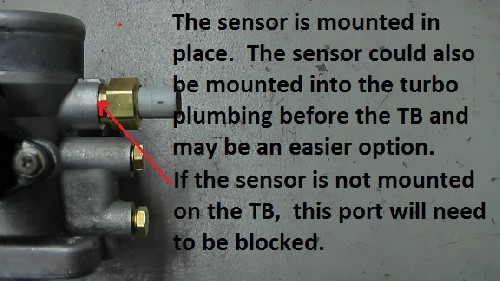

This first series of pics shows how to adapt the throttle body to the standard manifold.

IMGA0046 Resize.jpg (97.86 KB)

IMGA0046 Resize.jpg (97.86 KB)

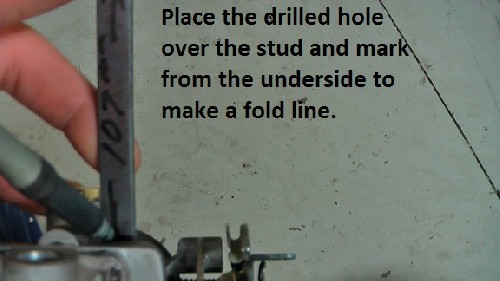

Transfer

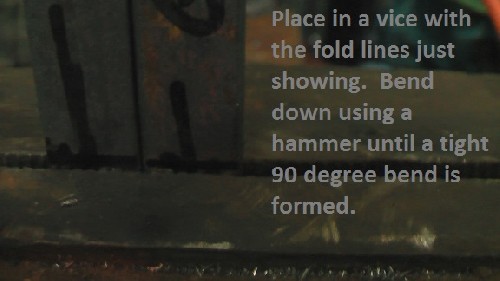

Transfer