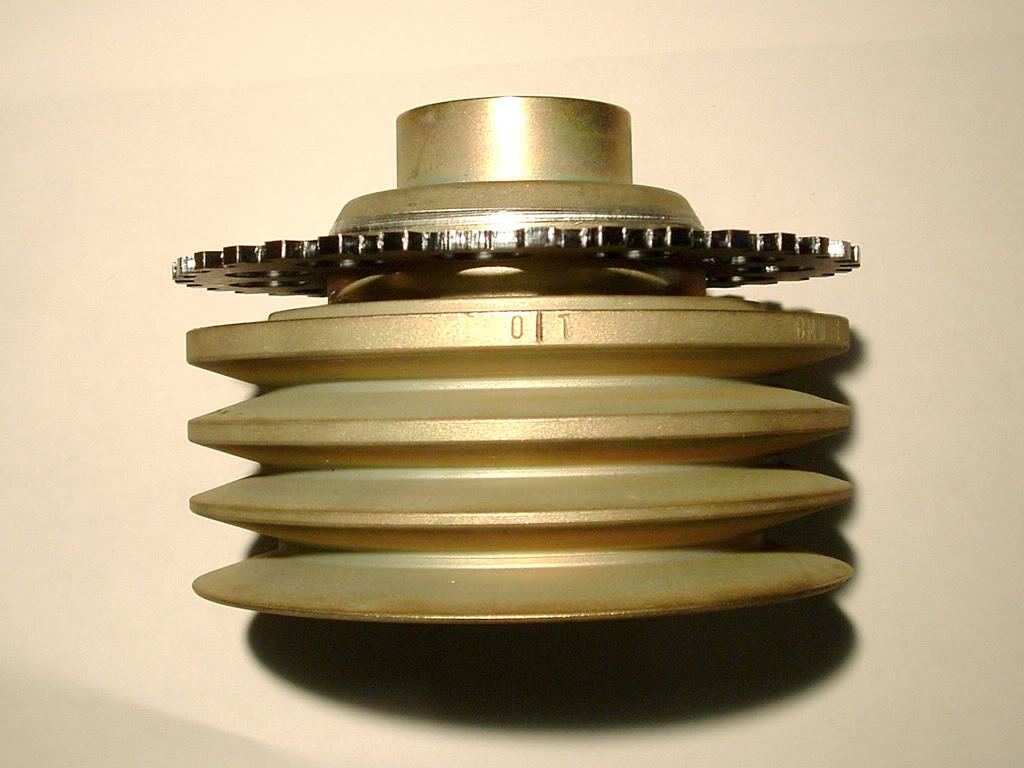

The pulley's cast iron so I would recommend against welding. Any mods to the pulley you should try and do the same either at 180 or 120° intervals, that said the missing tooth wheel will not be perfectly balanced and is pretty minor in the scheme of things, there's not a lot of section in the pulley so it might be challenging.

Here's what I did;

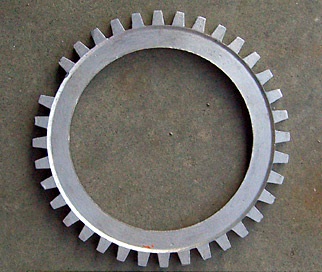

http://datsun1200.com/modules/myalbum/photo.php?lid=25476.I fitted a Ford trigger wheel to one of these pulleys but getting a fitter mate to turn down the shoulder your talking about to 114mm and removing the front pulley. He then opened the trigger wheel to 114mm, a sliding fit and I epoxied it in position. Epoxy works well if the two metal surfaces are fresh and clean and it's only under inertial load. From memory the Ford wheel was too small to just open up to the shoulder diameter but if you're buying one you could buy a bigger one?

I hope this is helpful, you might find a similar solution works for you.

Transfer

Transfer

Damper1Small.JPG (33.64 KB)

Damper1Small.JPG (33.64 KB)