How to build a cost effective EFI turbo setup that is upgradeable in the future. Big Power from stock-block A12 can be had by adding a turbocharger. Unmodified short block with stock pistons, crank and rods, and standard head gasket makes 160HP.

Contents |

A12 Overview

See: * Turbo EFI A12 for under $1200. Build thread * Forum: Turbo EFI A12 for under $1200. Discussion thread * A12 Turbo Development thread See how he got to the $1200 A12 Turbo EFI

The basic initial setup uses the standard A12 inlet manifold fitted with a single Throttle Body and a single injector. The ECU is a MicroSquirt V3, which allows for future upgrades like adding multiple coils and injectors later, as well as boost control. Turbo is a single turbo from a twin turbo Nissan Skyline(there are plenty of Upgrade options if you want more power later on).

160+ rwhp @ 15 lbs boost(standard H89 Head) 240+ rwhp @ 24 lbs boost(big valve ported head) 2nd-hand GT2860R (707160-5) ball bearing turbo E85 fuel, intercooled stock and unmodified H89 head Cam: 236 degrees at .050 lift 600cc Siemens injectors Maximum advance at 16 psi boost: 23 degrees ARP head studs stock pistons, crank and rods standard headgasket E85 fuel 71C thermostat 16 psi high-press radiator cap about 120 Lb. ft. from 5100 to 6800 RPM @ 15 psi

For racing: * add oil cooler to keep temps at 100c

Fuel

E85 alcohol fuel is superior to high octane pump gasoline for turbo applications. Similar to, but more available and less expensive than Racing Gasoline. It's also legal for highway use where racing gasoline is not.

Lambda is set to be .86 at 100Kpa richening to .75 at 175Kpa

Turbo

Stock Turbo off twin turbo Skyline ($100 secondhand) is limited to about 12-14psi because they are made with a ceramic turbine impeller. Much more boost than this, these turbines tend to fly apart.

GT2860R (707160-5)

Upgrade to Inconel steel turbine wheel and rebuilt kit is about $380, but allows higher boost.

Head Gasket

Standard A12 head gasket was used (Durapro brand, $18 AUD) ARP head stud kit

Cylinder Head

Light skim of the H89 head, not to raise compression but to recondition the used head.

Camshaft

236 deg at .050"

That's probably one of the biggest reasons it was falling over as much as it was after 5800 RPM (increased the boost past where peak torque was to keep it holding torque). Its actually increasing from 16Psi at 5500 up to 22psi at 7200 to keep the torque curve climbing slightly.

NOTE: The stock A12 camshaft is 248 degrees "advertised" duration, not duration from .050" lift. Advertised duration is a bigger number, and will be less when measured at .050" lift.

Boost

16 psi @ 5500 22 psi @ 7500

Under electronic control to limit mechanical overload of the piston, to avoid breaking the ring lands or flexing the pin and distorting the piston. These stresses are highest at peak torque. The stock A12 pistons have been surviving at 150 lb ft, so to maintain that torque(average cylinder pressure) higher into the rev range requires more boost up high. If I ran 22 Psi everywhere, the cylinder pressure could be too high for the pistons.

The 150 Lb Ft torque figure is derived from torque at the axle, divided by the diff ratio. so its like the engine torque, but not including the driveline losses.

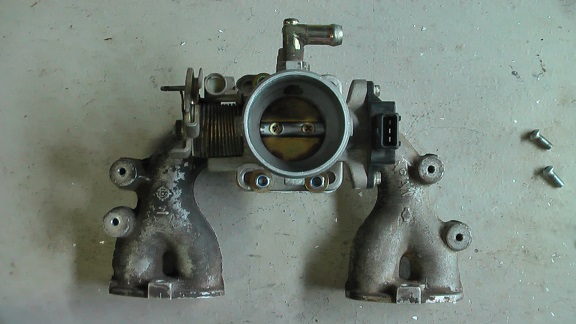

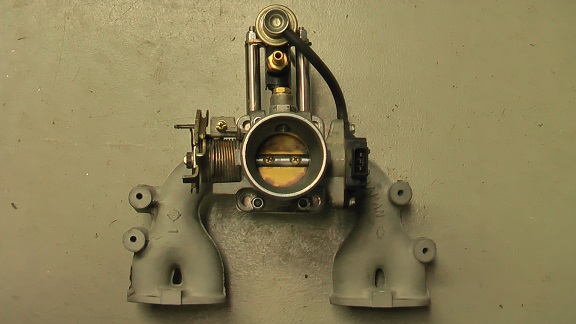

Inlet Manifold

Rather than fabricate a custom manifold, the stock one works well for a road car with a mild cam.

On a turbo engine, boost is usually the thing that has the biggest impact on the torque curve. Much more so than intake manifold runner length.

- Stock A12 intake manifold

- Throttle body from a X3 SOHC Hyundai Excel

- Fuel Pressure regulator from a 1997ish Misubishi Lancer or Toyota Corolla

- 3-5mm thick alloy plate for the adaptor

- 1x Fuel Injector (1000cc for petrol; 1300+cc for E85)

Mounting the injector, fuel rail and fuel pressure regulator

Exhaust Manifold

Ignition

Coil on Plug ignition was used to generated the 160HP. But a move to ordinary coils and leads makes it easier.

Ignition timing is: 30deg BTDC at 100Kpa (atmospheric pressure) and peak torque.

Engine Life

Engine life, is an interesting question.

- With moderate boost, the peak cylinder pressure isn't much higher than a non-boosted engine. But the pressure is maintained for more of the power stroke. Because of this, loads on rods and bearings don't go up much. Its more a matter of thermal management, things like pistons and cooling systems can be quickly overcome because the extra time the force/heat is applied per power stroke.

- Ring wear would go up a bit because its forced against the bore longer on each power stroke compared to naturally aspirated (NA).

- Keeping the standard pistons from overheating is probably the biggest concern. That's where E85 is a huge help. Good intercooling plays a big part too.

- The engine management system can also play a big part in saving an engine. Things like Compensation tables set up to retard ignition as intake temps rise or Electronic boost control backing off boost if EGT`s get a bit high.

At the 11 psi boost level, I'd expect 100,000 km on a road car with sensible rev limits and general good treatment. Or a season of racing. But get something wrong with the tune and it might last 5 minutes if its allowed to detonate.

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)