The H95 engine was created to comply with 1981 emission standards, improve fuel economy and increase driveability, the A-series engines for USA and Canada have undergone several modifications. All engines now use the same head design, cam & valves. All 1981 engines use a 248 degree camshaft, whereas previous A14/A15 used a 256 degree cam. 1981 is the origin of H95 engine parts.

Contents |

Datsun 210

For the B310 chassis, an A15 engine has replace the A14 engine model formerly used with the manual transmission. The A14 engine has also replaced the A15 engine in MPG models, providing a new addition to the current selection of models available for non-California and Canada destinations.

FU models for 1981-1982 did not have a special engine, but instead ALL 1981-1982 US models, including A12A, A14 and A15 used the same high-efficiency engine design with small oval ports and smaller intake valve.

Datsun 310

An A15 engine has also replaced the A14 engine formerly used in the N10 (Pulsar) front wheel drive chassis.

Engine Mechanical System

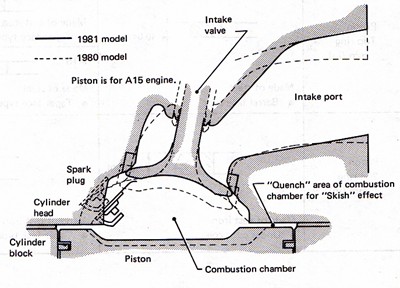

To meet emission control standards and to improve combustion properties, the following modifications have been made:

- In order to increase the "skish" effect, the combustion chamber design has been modified and the lower surface area of the combustion chamber has been reduced. In conjunction with these change the valve seat has been installed in a slightly higher position.

- The spark plug has been moved 6 mm (0.24 in) closer to the center of the combustion chamber for increased ignition performance.

- Weirs have been added inside the intake port to increase the "swirl" effect. Additionally, the cross-sectional area of the port has been increased in relation to the reduction of the intake valve diameter at the bevel.

Small oval ports replaced the round ports of previous FU heads, and also replaced the large oval of previous A14/A15 standard heads.

- quench head

- smaller dish in piston

- 35 mm intake valve (previously 37 mm)

- shrouded intake valves

- change from Round ports to Small Oval

Valves

To accomodate the new combustion chamber design, the intake and exhaust valves have been shortened by 4 mm (0.16 in) and the diameter of the intake valve at the bevel portion reduce from 37 mm dia. to 35 mm dia.

* 1981 length: 100 mm * 1980 length: 104 mm

* Exhaust valve head: 30 mm * Intake valve head 1980: 37 mm * Intake valve head 1981: 35 mm

Part Numbers (100 mm) 13202-H9500 VALVE-EXHAUST 0880- [30 mm] A12A, A14, A15 13201-H9500 VALVE-INTAKE 0880- [35 mm] A12A, A14, A15

Valve Length * Intake: 37mm, 100.0 mm * Exhaust: 30mm, 100.0 mm NOTE: All other A-series valves are 103.8 mm long

Piston

The crest of the piston has been redesigned to accomodate the new combustion chamber design. The piston ring groove has also been modified to match the new top ring design.

The specifications for the piston rings used in the A14 and A15 engines have been revised for lower oil consumption.

Top Ring * 1980: Barrel type face 1.2 mm steel * 1981 A14: Taper type face 2.0 mm cast iron * 1981 A15: Taper type face 1.2 mm steel

2nd Ring * 1980: Taper type 2.0 mm cast iron * 1981: Under-cut type 2.0 mm cast iron

Camshaft

The cam profile and its operating angle have been modified for increased stability during idle and increase torque at low speed.

1981 Duration: 248 * 1980: 256 for A14/A14, 248 A12A 1981 Valve lift: 5.60 mm * 1980: 5.33 intake, 5.60 exhaust 1981 Overlap: 32 degrees * 1980 A14/A14: 34 degrees, A12A: 26 degrees

Part Number 13001-H9800 CAMSHAFT 0880- A12A, A14, A15

Intake Manifold

The intake manifold has been re-designed to match the cross-sectional contour of the oblong intake port. In addition, the riser has been installed in a slightly higher position and a groove has been added to the intake ports for easier starting when the engine is cold. The manifold gasket has also been modified.

Groove at bottom of runners * Datsun 210: #1 and #2 branches * Datsun 310: All branches

Fuel riser: * Raised about 5 mm (0.20 in)

wet intake, Small oval ports 14035-H8901 manifold gasket (same as Large Size ports)

Exhaust Manifold

The 1981 exhaust manifold is based on the 1980 FED (USA, non-California) model with the following modifications:

- To increase the flow of secondary air, the diameter of the secondary air passage hole has been increased from 11 mm dia. to 18 mm dia.

- The diameter of the E.G.R. tube mounting screw has been changed from M20 x 1.5 to M22 x 1.5 for increase EGR flow

On California models, the same exhaust manifold as described here is utilized due to the adoption of an air induction system.

Cylinder Head

H95 were the ONLY heads for 1981 and 1982 in USA. So they are very common. Most guys want the high-power heads, so these high-torque ones are very available.

Small oval with swirl obstruction. These are good for emissions and fuel economy (H95 head, 1981-1982 USA all engines). They make excellent power at midrange RPMs.

This head does not have the air injection ports in the exhaust valve pockets. The air injection was done via the exhaust manifold using the pulsing of the exhaust to draw air through stainless steel pipes that were connected to reed valves in the air cleaner can.

Has an H95 cast into it, under the valve cover area

11041-H9500 A15 (H95 over #4 spark plug)

Part Numbers: 11041-H7285 CYLINDER HEAD ASSY B310 A15, A12A CAN 0880- 11041-H9500 CYLINDER HEAD ASSY B310 A15 CAL, FED 0880- 11041-H8700 CYLINDER HEAD ASSY B310 A14 FED, A12A CAL 0880-

Ports

H95 Oval: 28x30 mm H89 Oval: 28x34 - typical A14/A15 A12 GX Oval: 30x36

- Small-oval ports, guide is shrouded

Has what some call a "swirl" port has an obstruction cast into the port to cause the flow to swirl although it reduces peak flow. If you look into the port, from the manifold side, you'll see a heavily shrouded port, and looks much smaller than it would normally be on an A14 head.

Some say it can be ported very well, to very high flow rates.

Others have said if you try to grind out this obstruction, you will hit a water jacket and render the head useless. It too, has the coolant holes in it.

Combustion Chamber

They also have a small but deep combustion chamber, hence a different dish in the piston.

- peanut-shaped combustion chambers

H95: 35cc (A15 dish: 6cc)

D: heavily shrouded late-model design (H95)

EGR

Like any late-model engine, H95 had EGR.

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)