Datsun 1200 engines came in two basic forms: standard round-port manifold for 5,000-6,000 RPM operation, or GX oval-port for 6,400 RPM operation.

|  |

Contents |

Overview

There are two basic cylinder heads used by 1200s:

GX - extra high-RPM large oval-port inlets Standard - high-RPM round-port inlets

If you enjoy revving the engine up high, the GX head is preferable. If you like to keep the RPMs "reasonable" (under 4,000 RPM) then you will like the standard head better.

Compression Ratio

All 1200 cylinder heads had the same Compression Ratio. The pistons set the final ratio:

GX flattop pistons: 10:1 compression ratio Low-dish piston: 9:1 compression ratio (69hp, most countries) Deep-dish piston: 8:5 compression ratio (68hp, 1972-1973 North America)

Higher compression makes more power and returns better fuel economy, but requires better (more expensive) petrol.

10:1 requires Supreme/PULP (high octane) 9:1 can use regular grades of petrol

Newer A-series engines used a similar size combustion chamber. Generally speaking, if you want to change the CR, change the pistons instead of the head. Alternatively your existing head can be milled or a spacer used to vary compression. See Compression Ratio for more information.

Open Chamber

In USA, two types of combustion chambers were used. Starting in 1972 a less polluting "open" chamber head design was used.

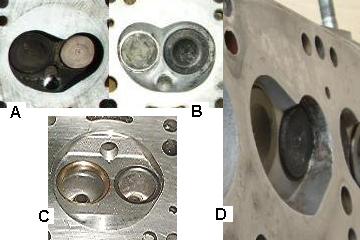

A/B: Closed chamber (quench head): Best power & fuel economy C: Open chamber: A touch less power, but far lower NOx emissions

The difference was 1 hp. However the closed chamber ran better on the same grade of gasoline with less tendency to ping/pink/knock, so the performance difference was noticeable. Even though the open chamber was used with lower compression pistons, it still had more tendency to ping because of the less efficient chamber design. That being said, NOx is the primary cause of smog and reducing it has cleaned up cities like Los Angeles.

Choosing

Which the best head to use -- A15, A14, or A12? and what are the benefits or disadvantages of each?

Which cylinder head is best depends upon what you mean by "best" -- Better fuel ecoif nomy? Better acceleration?

A12 head: 69 hp A14 head on A12: 73 hp with upgraded carburetor * (up to 80 hp if camshaft & exhaust are updated) GX head: 83 hp when carburetor, cam & exhaust are upgraded

A12: The head is best for convenience (if your 1200 already has it and is running well). Best for fuel economy, yet still provides sprightly fun and revs hard to 5,000 RPM (6,000 RPM with a carburetor update).

A14/A15 round port cylinder head is not a noticeble change from the standard A12 head, although performance over 4,000 RPM is slightly better due to the larger valves that all A14 heads carry.

A14/A15 oval-port cylinder head makes more power in heavy-throttle, high-RPM use (in the 4000-6000 RPM range). The most common is the H72/H75 head, which is usually an open chamber design that matches well with the stock dished pistons. For best power and fuel economy use flattop pistons use an H89 head in order to get quench benefit.

A12GX large-oval cylinder head is best for most power (in the 4600-6400 RPM range) when used in conjuction with a larger duration cam, such as the GX camshaft (6400 RPM cam). Unfortunately most GX heads are now worn out or have softened due to racetrack overheating.

A12/A14 H95 is the best head for medium-RPM use (3,000-5,000 RPM). It has the power-beneficial closed chamber design, a high-swirl port for superior fuel economy combined with high port runners for good flow. This came in mid-1980s A12/A14/A15 engines. It has the largest combustion chamber of all A-series heads, so using it with flattop pistons is recommended (which also makes the desired quench factor work).

NOTE: When swapping cylinder heads, obtain the matching intake & exhaust manifolds. Many newer heads require a different inlet than the A12, and the A12 exhaust won't bolt to it. So get a matched set.

Mixing & Matching

Can I use an A14/A15 head on an A12 engine?

Yes, definitely. To use A14/A15 head on A12 these factors should be considered:

A12 type

- if fitting to an old-style A12 block (1970-1973), create the oil passage needed for the head

- if fitting to a new-style A12 block (1974-1994) it simply bolts on

Exhaust pipe

- A14/A15 uses 3-bolt exhaust flange. Most A12s use 2-bolt pipe

Manifolds

- A14/A15 head might be round-point, or oval port. Get matching manifold set

- Head might use water-cooled manifold, so get matching manifold set

- use matching intake & exhaust manifolds. Divorced exhaust manifold won't fit Heat-riser type intake, and vice versa. So get a matched set

Chamber Type

- Some A14/A15 have a quench head, meant to be used with offset-dish pistons

- Late A15 (some 1982-up) have a large chamber head 35cc compare to typical 31cc of early heads. This is enough to cause a small loss of power unless fitted with small-dish pistons

What's the difference between A14 and A15 cylinder heads? No difference, all A15 heads were originally created for and used by A14s. They come in various types (round port, oval port, medium oval port, with wet or dry manifold systems).

Could I use an A12 carb on the A14/A15 inlet? Yes, but it is a smaller carburetor (venturis of 20/26 instead of 23/27). That means HP will be down, however it will run very well below 4000 RPM. For best results use an A14/A15 carburetor.

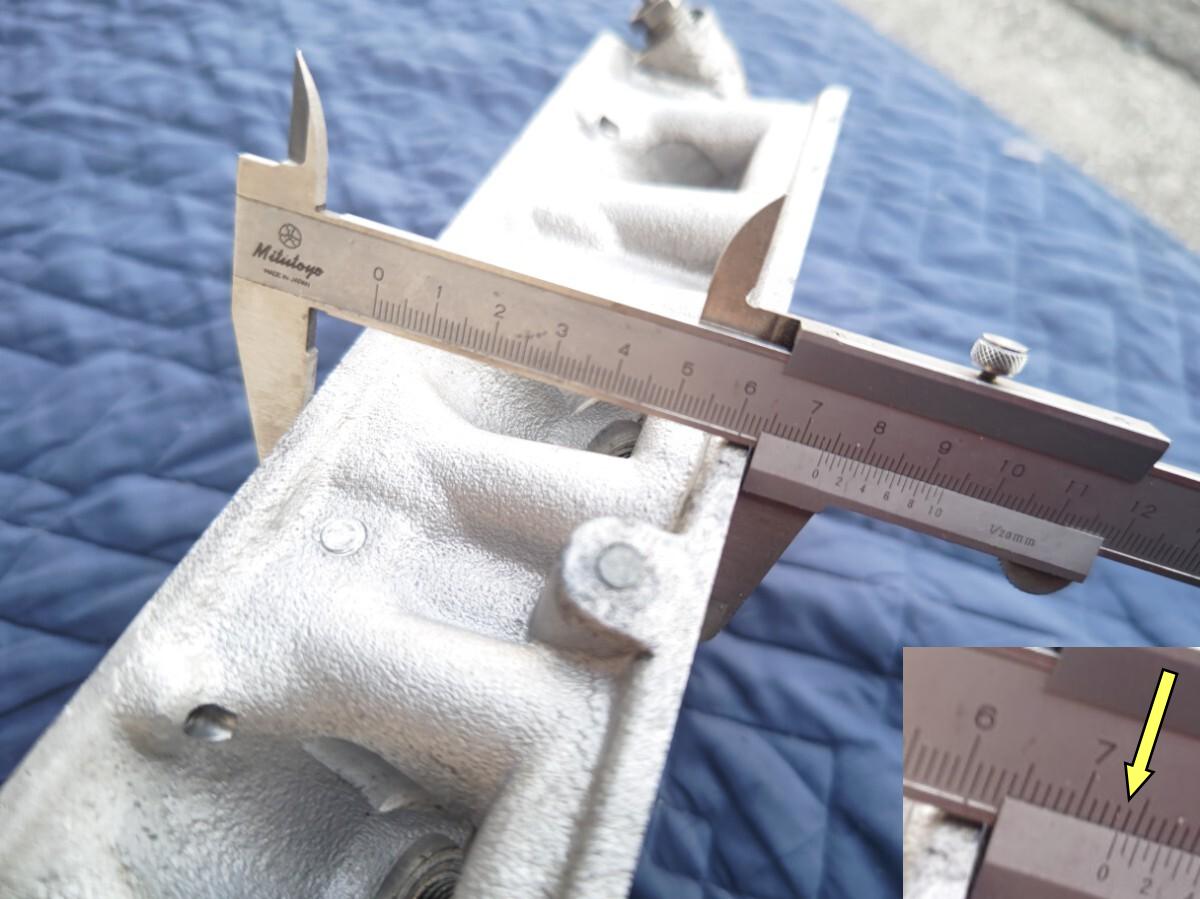

Head Thickness

Virgin cylinder head thickness is ~74 mm. This seems consistent across the different A12 castings

this one measures 73mm, indicating it has been milled 1 mm (0.040"/40 thousands inch)

Measuring the cylinder head surface lip varies by the casting

Inspecting a used head

1. Check surface flatness yourself. Most A12 do not need head skimming (head milling). Use a straightedge (I use a quality level) and a .004 inch feeler gauge. It is allowed to be up to .004 from flat but I rarely see that much even after overheating and blown gaskets. Normal is .002 inch (.1 mm) per the Datsun factory service manual.

2. carry a water bottle. Place the head upside down and fill the combustion chamber with water. If it holds for 5 minutes, the valves are sealing good and do not need a regrind.

3. check for play on a valve stem. Use a small valve compressor (I paid $10 for one at a flea market) and see if the valve is tight side-to-side. If it's not, go on to the next head. If it is tight, check a few more (or all of them). There should be almost no discernable wiggle with the valve slightly off the seat. If there is, it requires new guides ($$$).

4. Visually inspect for gouges in the head face and manifold faces. Clean-looking heads are best. Pass on slightly rusty heads. Wiggle the valves to see if the guides are OK (this is the part most often wearing out on A12).

Self-serve wrecking yards have a warranty if you want to do the checking at home.

Checked for hardness + pressure tested is normally $20-30.

Damage

Overrev damage. Either the valve head broke off, or the rod moving down pulled the middle of the piston out.

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)