At first glance, all A-series cylinder heads look alike. But by careful notice of specific features you can identify the model.

|  |

Contents |

Overview

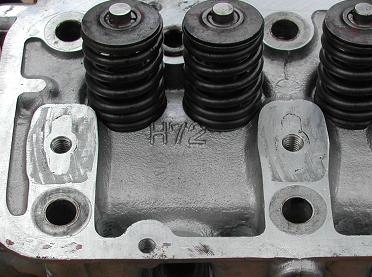

For the cylinder head, the best way to tell which head you have is to check the casting number in the valve train area (remove the rocker cover to look for this number).

If the head you are looking at does not have a casting number, see the next section: Distinguishing Features.

Once you have the casting number, see Nissan Part Number Prefixes for a table of the different model to part numbers. For example, H23 means the part was originally designed for B110 GX models.

- A10 may have "180", "H01", "257", "H03" or no markings at all

- 1971-1973 A12 may have "180", "H10" or "H39". Some have no markings at all.

- A12 GX may have "H23" or "230"

- 76 Sunny trucks (A12) may have M30, G25, G61

- 1974 A13 may have "H62" or "620"

- A14 could have several different ones, such as G32, H72 (or 728), H74, H75, H77, H78, H85, H92 or H98 depending upon year, country, and emission control design.

- M24 or 246 is A14T (Hitachi Twin Carb engine)

- H85 is A12 or A13 (newer engines)

The casting number will be the first 3 digits of the last half of the part number, as all cylinder head part numbers begin with the same 5 digits (11041). For example:

11041-H2300 or 11041-H2301 HEAD ASSY-CYLINDER A12 GX * 11041 is the base part number for all cylinder heads * "H23" means the part was first used on the B110 GX vehicle. * "728" is short for H728x, indicating a B210 "H72" part

references:

- Nissan Part Number Prefixes

- Discussion: Various cylinder heads

- Discussion: A14 head--728-402

ID Marks

You may find many marks/engravings/casting numbers on a cylinder head. Original A12 heads have no marks. Remove the rocker cover to see the key marks.

These are the important marks:

For example, this head has rear mark 'H75'

Look up the Type mark at A-series Cylinder Heads

The front Mark can sometimes help further identify the head.

Early or Late?

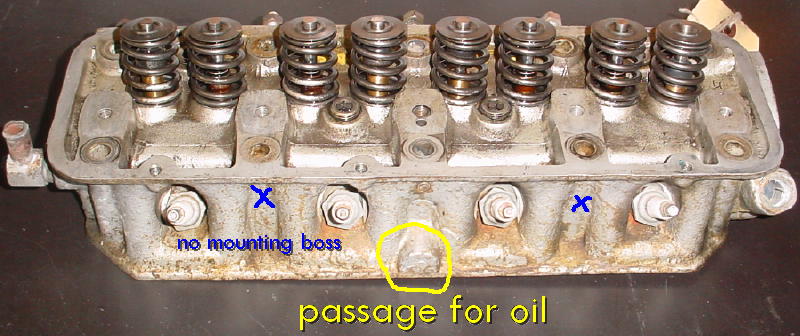

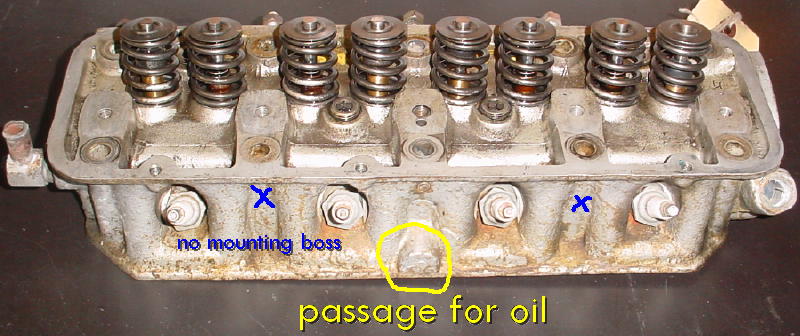

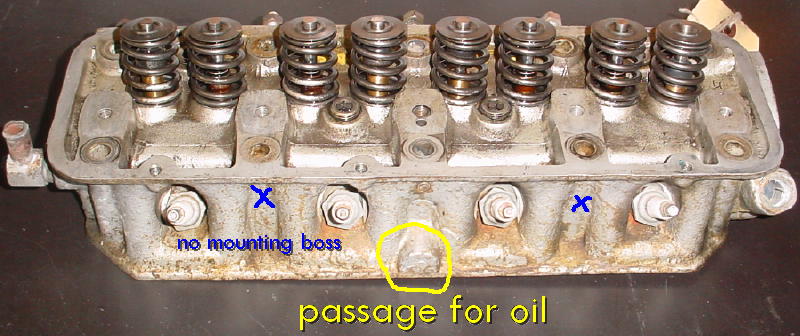

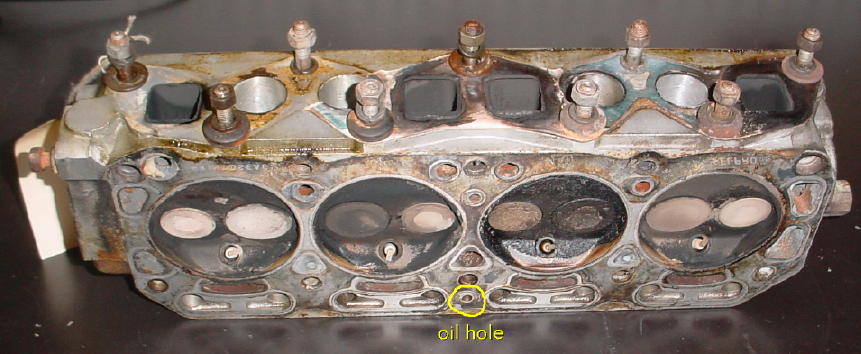

To determine if the cylinder head is from a pre-1974, or 1974-onwards engine, check for the presence of an oil passage, located here:

Only pre-1974 engines will have this passage in the cylinder head, from factory. It is, however, possible for this oil passage to be drilled on a 1974-onwards engine. But it is a good indicator nonetheless.

For verification of an original, pre-1974 cylinder head, inspect the cylinder head for the following:

Pre-1974: Oil passage boss.

1974-onward: No oil passage boss present.

Distinguishing Features

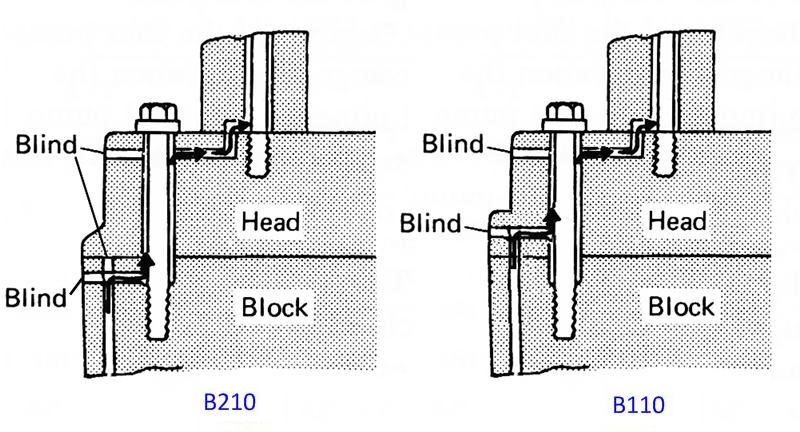

Any A-series cylinder head can be bolted onto any A-series engine block. However, compression ratio, port size (oval port, and round port), and manifold stud pattern need to be taken into consideration. Naturally, it is best to match port type, and size (e.g round port manifold, and round port cylinder head). The most critical difference, is the rocker shaft oil passage. It was relocated in 1974, as part of the A-series engine redesign.

Cylinder head oil passage

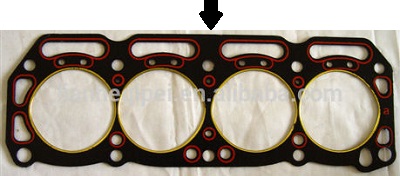

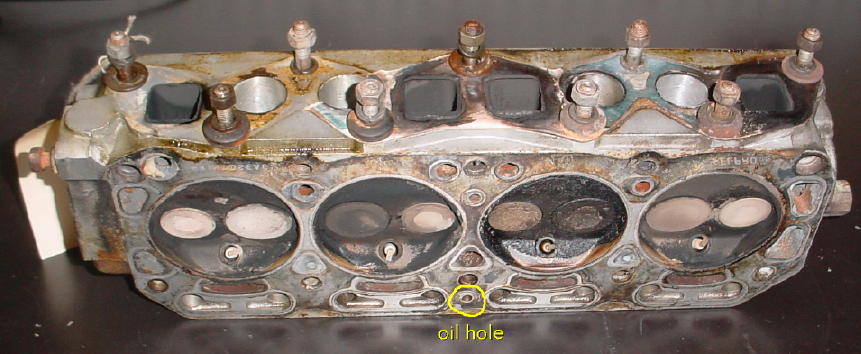

An extra oil passage in the cylinder head is required, for some engines. For pre-1974 engines, ensure your head gasket has the corresponding hole! You can punch, or drill, a hole in the head gasket if necessary.

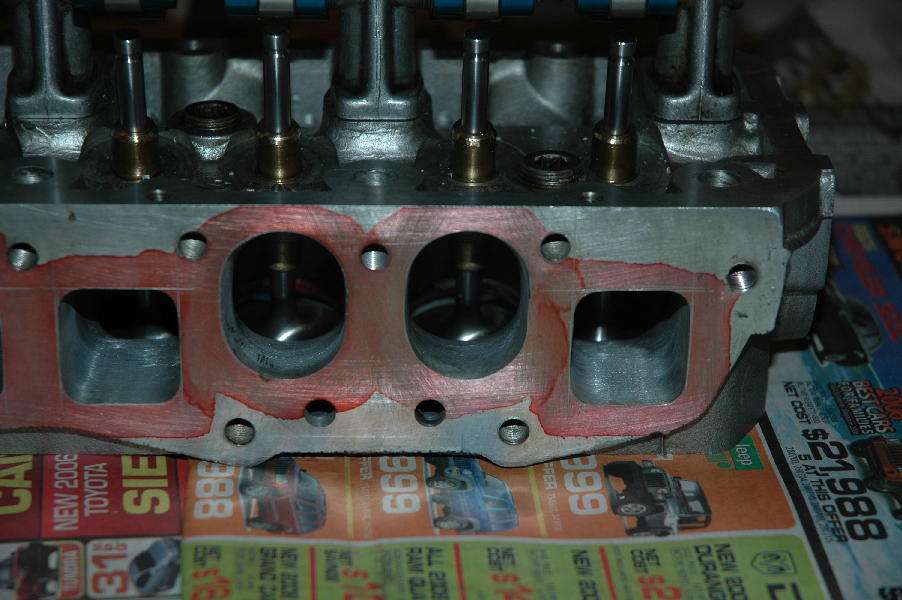

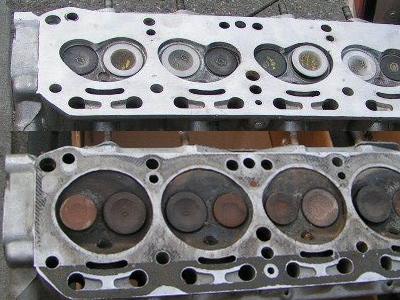

Top: 1974, no oil passage. Bottom: 1973, with oil passage.

The older 1967-1973 head has the oil passage:

Boss, on the exterior, for cylinder head identification.

Comparison to 1974-onward cylinder head: no oil passage. The newer, redesigned engine has the oil passage in the engine block instead.

Late blocks do not send the oil up through the small passage, so do not need the hole in the gasket. Instead oil flow through the head bolt hole. So late blocks can work with either old or new heads. See Block_Comparison#Head_Oiling

Factory installed brass plug in late block

Interchangeability

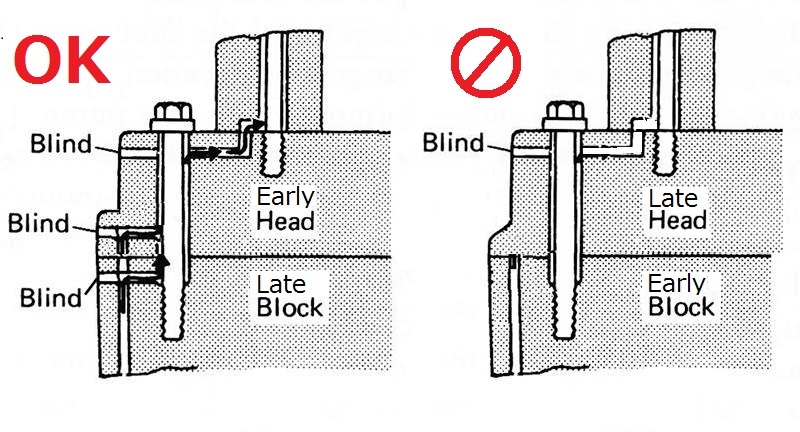

Any cylinder head old or new can be used with old or new engine.

- A pre-1974 cylinder head will bolt onto any engine block, with no modification required.

- A 1974-onward engine block will work with any cylinder head. But, in the case of bolting a 1974-onward cylinder head to a pre-1974 engine block, a minor oil passage must be created.

I took off the head, marked it with the old head gasket, and drilled it on a 45° angle. junior

Method 2: Cut the head gasket between the oil feed hole and the center head bolt hole:

I have seen a crude system where a 1200 head gasket was placed on the head to determine the position of the oil feed hole in the block. This was centerpunched & a very shallow hole was drilled. [about 1 to 1.5mm] then an angle grinder was used to grind a small trench across the gasket face to provide an oil passage froom this shallow hole to the nearest head bolt hole.Crude as hell, but it worked. A very steady hand would be a prerequisite.

Personally, I would suggest a milling machine if this method is used.

question about oil blockage

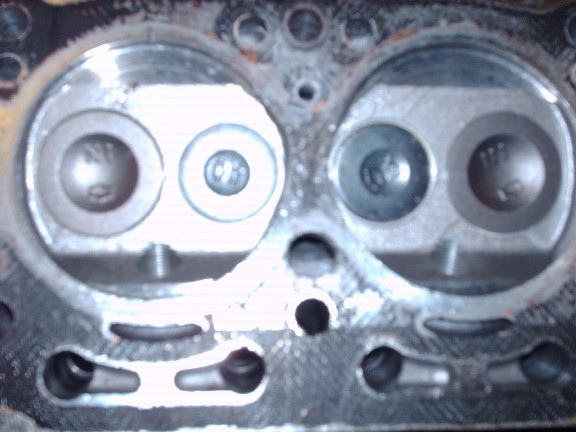

Combustion Chamber

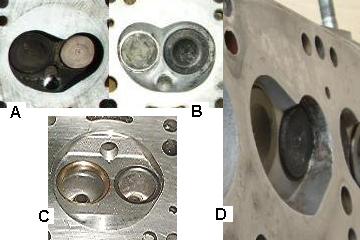

All Datsun A-series production cylinder heads have a wedge-shaped combustion chamber. However, most USA models are equipped with a cylinder head that is open-chambered, for lower NOx emissions. The 'heart-shaped' combustion chamber has a superior power output due to the closed-chamber design, with a large quench area.

- A,B: Heart-shaped high-compression chamber - good for maximum power and fuel economy

- Also known as closed-chamber, peanut-shaped, butterfly-shaped or kidney-shaped.

- C: 360° open chamber, for reduced emissions.

- D: Bathtub chamber (from 1982 Sunny Truck G61 head).

Any combustion chamber design will work on any A-series engine.

The classic closed chamber is less likely to ping with low-octane fuel. When paired with flat-top pistons, it requires high octane fuel

Comparison - Closed Chamber vs. Open Chamber

Open Chamber (small CC, high compression, but nevertheless an open chamber)

Chamber Size

- A12 closed chamber: 27-29cc

- A12T: (M08 head) 32 +/- .5 per 1981 Nissan Racing book

- for 11:1 with GX flat-top pistons, GX headgasket,

- mill head 0.9mm (0.035 inch) for 25.6 cc

- A12 GX: 29.1 cc (as per FIA papers)

- H75: 31cc

- H89: 29-31cc

- H92: 31cc (A14E head) 29.1 +/- .5 per 1981 Nissan Racing book

- H95: 35cc (A15 dish: 6cc)

Intake Ports

- Round - Best for low-RPM operation (more power under 4,000 RPM)

- Small oval (28 mm x 30 mm). The 1974 A13 has this design.

- Small oval, with swirl obstruction. These are better for emissions and fuel economy (H95 head, 1981-1982 USA all engines)

- Regular oval (28 mm x 34 mm). These standard A14/A15 ports are best suited for high-RPM operation, or for the larger displacement engines.

- ^Regular oval (28 mm x 34 mm) notched for injectors. A14E/A15E 92HP engines

- Large oval (GX and A12T, 30 mm x 36 mm). From A12GX Engine and B210 or Cherry A12T engines.

The cylinder head for the A14 EFI engine has less intake and exhaust resistance.

Datsun Competition Tune-up Manual model N10 Series (March 1982 Pub. No. CT2E-0N10P0)

GX Oval vs. A14 Oval Comparison.

Top: GX ports go much higher than A14/A15 ovals.

Port Shape

Early head with oval ports is either an A12GX head, or its twin, the early A12T head from the Nissan Cherry (E10). These are the high-revving heads for the factory Hitachi Twin Carb engines.

Exhaust Ports

All heads have nearly square exhaust ports.

Intake Ports

* Round port 28mm: A12 * Round port 28mm lowered: A14 GFU * Small Oval port 28x30mm: A13, A12A * Medium Oval port 28x34mm: A14 * Large Oval port 30x34.5mm: A12GX Engine

Port Sizes

| Ports | Size (mm) | Exhaust | Raised | Note |

| round | 28 | 27x26 | no | 1971 A12 |

| round | 28 | ? | lowered | 1977 GFU |

| Oval - Small | 28x30 | ? | no | 1973 A13 |

| Oval - Medium | 28x32 | 28x26 | no | A14E, A15E |

| Oval - Regular | 28x34 | 28x26 | no | Many A14s |

| Oval - Large (GX) | 30x35 - 36 | 27x29 or 28x26 | Yes | A12GX (1971-1973) |

GX extra-large oval ports (36 mm tall)

Wet, Dry Intake Manifolds

Coolant passages are below the intake ports (present or not). If present, they can be large holes or small holes.

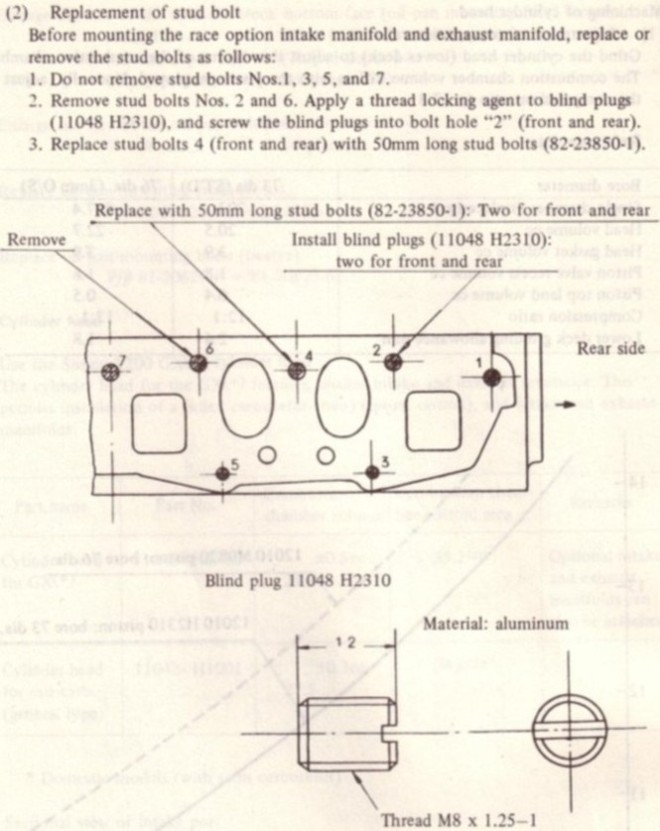

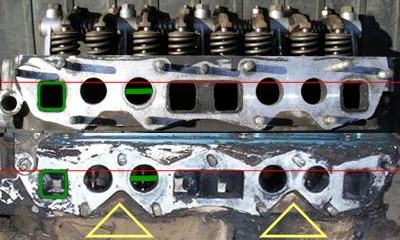

Intake/Exhaust manifold bolt pattern

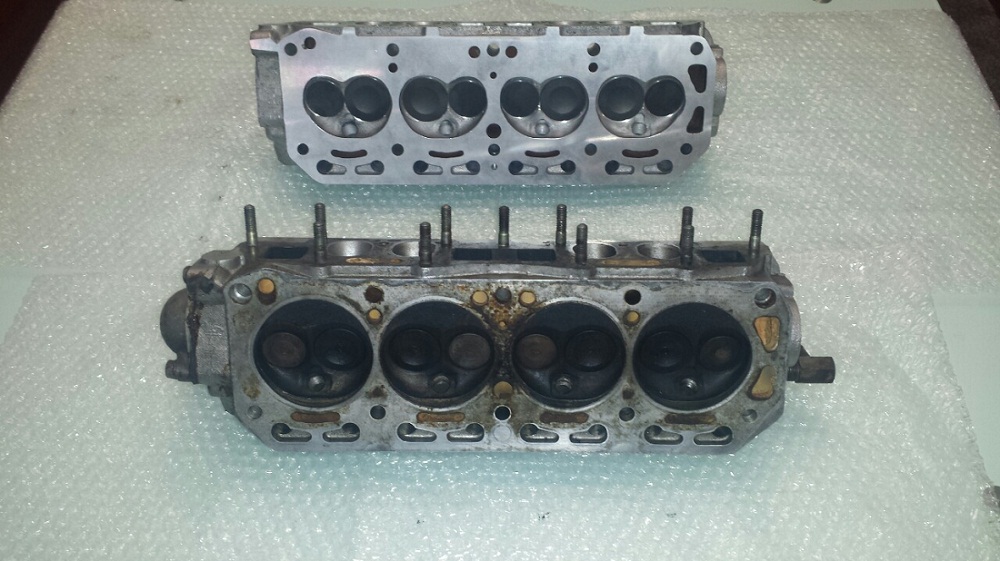

Early A12 differs from the A14. A12 changed in 1976, but A12 Wagons and Trucks continue to use the old pattern until 1979-1980.

Top: New bolt pattern

Bottom: Original bolt pattern

The bolt pattern on the cylinder heads also differ. early A10/A12 heads are only drilled for the older pattern. Newer A12 (1980s/1990s) are drilled for newer pattern. Some newer heads are drilled for both.

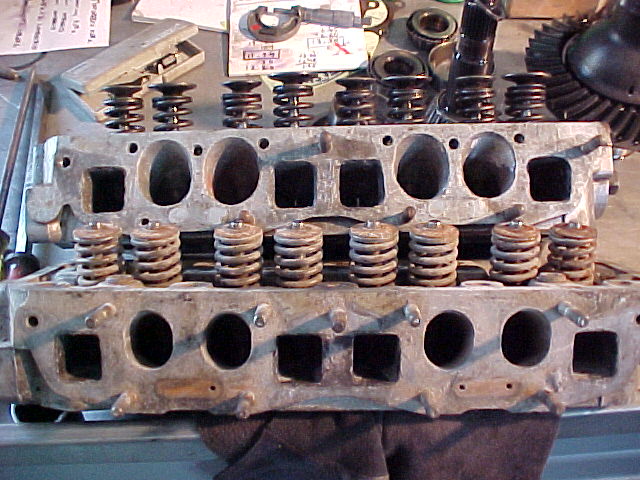

Valve Springs

The following A-series heads had dual valve springs. There is a small-diameter spring inside the main spring.

- A12GX

- early A12T

- late A12T

- A14T

- A14E, A15E

- Heads retro-fitted with dual springs

So dual springs are a good indication of a special head, but not conclusive. You will need to check the intake port sizes and other features to make a final determination.

Valves

All A-series engine use valves with 8mm diameter stem| Valves | Intake Part No. | In. Size | Exhaust Part No. | Ex. Size | Length |

|---|---|---|---|---|---|

| A10, early A12, late A12 Van | 13201-H1000 | 35mm | 13202-18000 | 29mm | 103.8 |

| A12GX/A12T | 13201-H2300 | 35mm | 13202-H2300 | 29mm | 103.8 |

| Late A12, A13, A12AS | 13201-H2300 | 35mm | 13202-H7400 | 29mm | 103.8 |

| A13(1974),A14 & A15 | 13201-H6200 | 37mm | 13202-H6200, 13202-H8900 | 30mm | 103.8 |

| A12A, A14, A15 1981-82 USA | 13201-H9500 | 35mm | 13202-H9500 | 30mm | 100.0 |

| A12A, A14, A15 1981-82 canada | 13201-H6200 | 37mm | 13202-H6200 | 30mm | 103.8 |

| Nissan Competition tuliped | 99996-H1100 | 37mm | 99996-H1100 | 30mm | 103.8 |

A12GX Identification

A true A12GX cylinder head has all these features:

- Dual valve springs

- No casting numbers

- Large Oval port 30x34.5mm. These ports are raised, and extend above upper intake bolts

- 27x29 mm exhaust ports

- closed combustion chamber - heart shaped, large size combustion chamber of 29.1 cm3

- large water holes (one under each intake port). Each hole is about the diameter of a pencil (non-GX heads have small holes)

- Seven upper intake face bolts, nine bolt holes (vs only 5 for other pre-74 heads)

- As with all pre-74 heads, Oil passage on head face (spark plug side), oil boss on side face between plugs 2 & 3 just above head face

- SAME valve sizes as standard A12: 29mm exhaust, 35mm intake

- NO bosses on sparkplug side between 1&2 and 3&4

One way to identify a GX, when the head is still installed: Look for the oil passage boss (indicating an early head), and for seven studs on the top of the inlet/exhaust manifold gasket. This combination is a good indicator of an GX (or early A12T) head. Regular early heads have only five studs along the top of the gasket.

- 5 mm water ports below the intake ports

- closed chambers

- oil hole between push rod holes for Nos. 2 & 3 cylinders

Early head with oval ports is either an A12GX head, or its twin, the early A12T head from the Nissan Cherry (E10). These are the high-revving heads for the factory Hitachi Twin Carb engines.

GX and A12T (non-GX) heads have small bulges on the top side (for the raised manifold bolts):

Datsun Competition heads have raised ports ceilings visible on the top face.

A12GX vs A12T

Datsun B210 twin carb A12 engine (A12T) uses a cylinder head nearly identical to A12GX. Differences include:

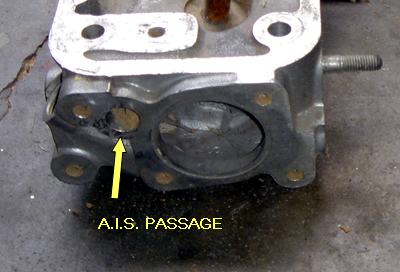

- Block face missing oil passage hole on B210 head

- Spark side threaded boss for B210 fuel rail

- Front side threaded boss for B210 high-mounted alternator bracket

- Rear face: no obvious differences

- Manifold face: no obvious differences

Four Sides

Head Front Face

- 3-bolt original type for left-side #Alternator Mounting

- 4-bolt, adds high right-side high #Alternator Mounting

- 5-bolt, adds right-side low #Alternator Mounting

- 5-bolt update (990 shown)

- 5-bolt with Air Pump air passage

- 5-bolt with undrilled Air Pump air passage (H75 shown)

Rear Face

WATER OUTLET early: low late: high

BOLT HOLE BOSSES * none * all the way to the left side * bolt holes in center

No bolts, high water outlet (original A12/13 style)

Air passage head casting H72 (air passage might not be drilled)

Spark-side Bosses

Look at the accessory/bracket mounting holes to help identify a cylinder head.

Variations * No bosses * One boss (between #1 and #2 near top) * Two boss (between 1-2, 3-4) * Three boss (between 1-2, 3-4, plus a front boss)

The bosses are used on newer engines for the fuel rail and Air Injection/Air Induction (EAI) pipes.

Three boss. Two top bosses and a front boss

No bosses. Early heads used a fuel rail that bolts to the valve cover

Two boss (example: G25 sunny truck head 1979-1989 and G61 1989-1994)

Air Induction (EAI) Pipe Brackets (B310.A13 shown)

Manifold-side Bosses

Variations * No boss * Front boss only * Rear boss only * Both Front and Rear bosses

In addition, bosses can be present but not drilled & tapped. For example, an H72 casting can be processed either way (drilled or undrilled). The difference merits a different Part Number, for example H72 casting part number 11041-H7200 and H72 casting part number 11041-H7240.

Front Boss location

Various fittings can be inserted: Plugs, switches or valves

Rear boss location

No Boss

Undrilled Boss

A12 with boss, not drilled (late B110)

Front Boss Drilled & Tapped

With boss (fitted with vacuum switch in this photo)

Front and Rear Bosses

Both bosses drilled and tapped (H72 107 industrial A14)

With rear boss not drilled, front boss drilled

Blank rear boss, tapped front boss

With rear boss drilled, front boss undrilled

Rear Boss Only

With rear boss (no front boss) H89

Alternator Mounting

Left Side

Early A-series engine (front distributor) mounted the alternator on the left side of engine, because the distributor and oil pump are on the right side.

- B10,B110,E10: on left side of engine, down low

- Upper bracket bolts to front face of head

Right Side

Late A-series engine moved the distributor to mid-block, freeing up room for a right-mounted alternator.

- B210, some B310: up high

- Upper bracket bolts to Upper bolt hole on head

- Some B310: up low

- Upper bracket bolts to lower bolt hole on head

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)