The Oil Level Gauge, commonly called a Dipstick, differs between early and late A12 engines.

Contents |

Overview

Short: ~9-1/16 inches from tip to bottom of rubber

Long: ~14-3/4 inches from tip to bottom of rubber

The long type has a flexible part riveted to the handle. The short type was a more expensive aluminum piece

If you rotate the A12 dipstick 180 degrees and put it back in, it hits the crank. Makes a crazy slapping, tapping, whacking noise.

Early type goes directly into block (1970-1973) so uses a short stick

H10 version is used by front-distributor A12 engine

Late type goes into a tube which is inserted into block (late 1973-up)

H50/H72/H95-type gauge is also used by B210 and B310 A12/A14/A15/A12A engines

Dipstick only goes in one way. Position it in so that the flat of the stick is parallel with the block so that it slides into the tube bend.

Oil Capacity

with oil filter change 3.2 Litres (2-7/8 qt) w/o oil filter change 2.7 Litres (2-3/8 qt)

The exact amount depends on which oil filter you use. Filters range from more than 1 litre to less than 1/2 litre.

When changing oil and filter, add 3 liters, then check the dipstick to see how much more is needed. From the L line to the H line is 1 liter.

Using the early right-side oil pan gasket on the late A-engine will result in the dipstick being wiped clean on removal, this will then make it appear as though the engine is low on oil.

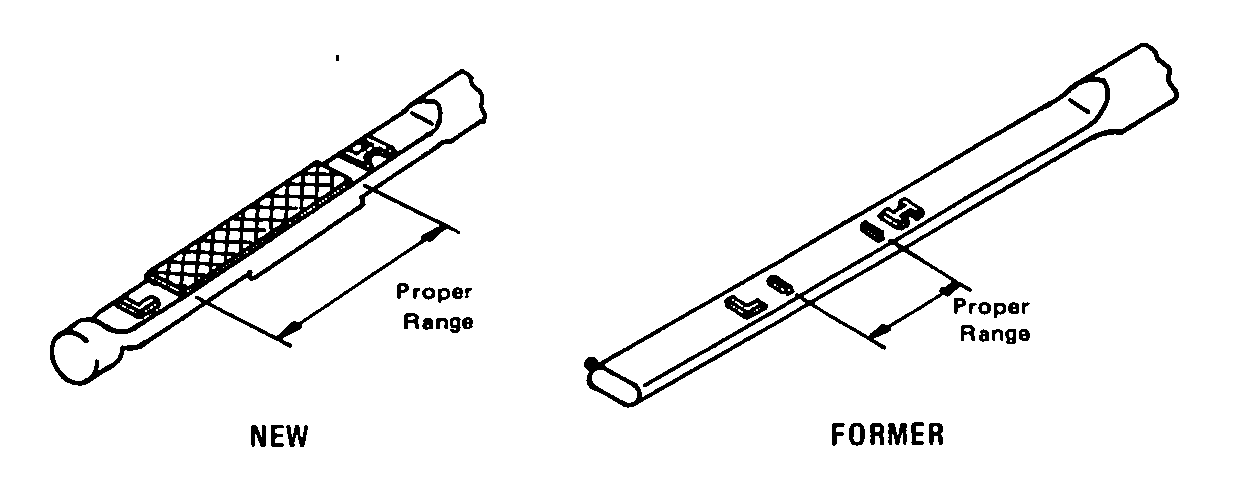

Updated Gauge

ENGINE OIL LEVEL GAUGE

Bulletin Number: TS72-18

Date: March 28, 1972

Classification Number: EN72-001

Section: Engine

Models: All

Production Change: The engine oil level gauge (dipstick) has been standardized for all models, with the level indication as well as the letters embossed on the rod

Beginning Engine Serial Number

A12-061093

L16-016014

L24-060520

Parts Information

New 11140-H1003

Former 11140-H1002

Engine Model: A12

Basic Vehicle Model: LB110 series

Interchangeability Yes

Part Numbers

Tube

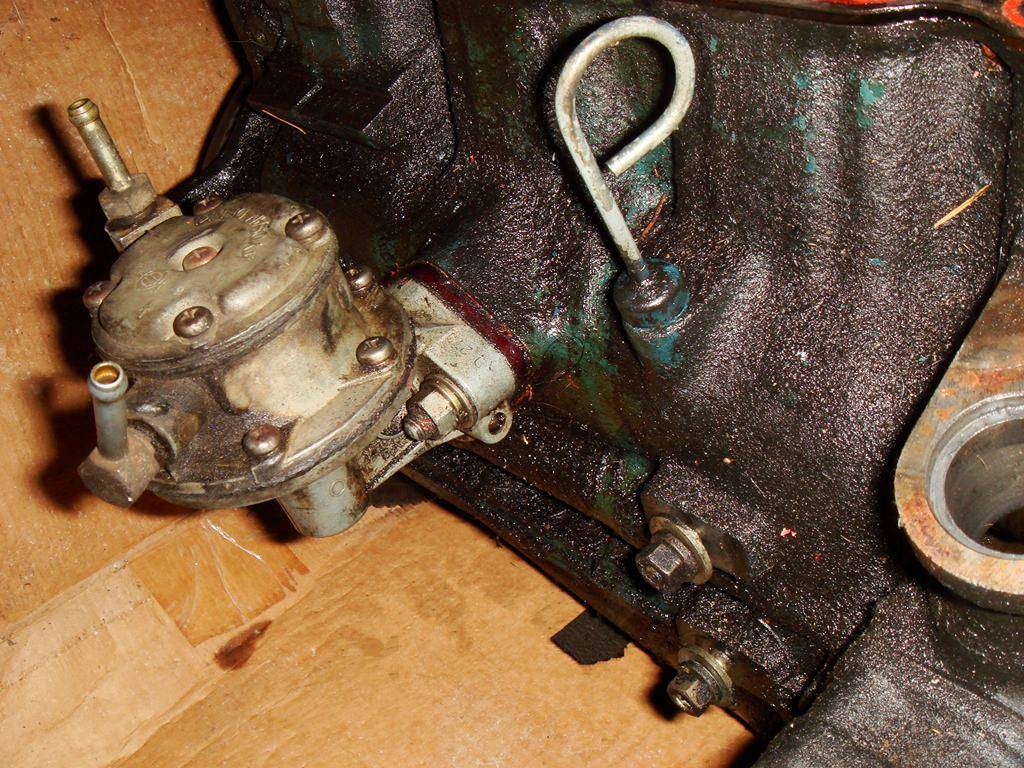

A tube is used by 1974-up engines (see A Engine Redesign).

Buy at Bprojects

15146 ASSY-GUIDE [Dipstick tube] see part numbers below

SPECIFICATIONS Insert point diameter: 9.1mm. Main pipe diameter: 10mm. Gauge point inner diameter: 10.2mm. Gauge pointouter diameter: 12.2mm. Gauge Insert length: 25mm. Bending degree: 12.5 degrees

1200

B110 USA + JPN 11140-H1002 GAUGE-OIL LEVEL A12 11140-H1003 GAUGE-OIL LEVEL A12 <> 11140-H1002 * USA: 0271-

B120 JPN 11140-H5001 GAUGE-OIL LEVEL -8808 NOK <> 11140-H5002 11140-H5002 GAUGE-OIL LEVEL 8808-8910 オオイセイサク 11140-H5010 GAUGE-OIL LEVEL 8808-8910 NOK 11140-G5101 GAUGE-OIL LEVEL 8910- 15146-H5001 GUIDE TUBE -8109 <> 15146-H5002 15146-H5002 GUIDE TUBE 8110-8910 15146-G2600 GUIDE TUBE 8910-8912 15146-G2501 GUIDE TUBE 8912-

RWD

B10 JPN 11140-18002 GAUGE-oil level <> 15140-18001

B210 USA + JPN 11140-H5001 GAUGE-OIL LEVEL * USA -0275 * dipstick L-H lines 1.3 liter 11140-H7200 GAUGE-OIL LEVEL 0375- USA 4/5 11140-H5001 * dipstick L-H lines 1.0 liter. See A-series_Engine_Changes#1976 15146-H5001 GUIDE TUBE B310 JPN 11140-H5001 GAUGE-OIL LEVEL [all engines, all years] 11140-H5010 GAUGE-OIL LEVEL -8010 [2nd source] 15146-H5001 GUIDE TUBE [all years] 15146-H5002 GUIDE TUBE 7910- B310 USA 11140-H5001 GAUGE ASSY-OIL LEVEL (NOK) A12A 11140-H5010 GAUGE ASSY-OIL LEVEL (OOI) A12A 11140-H9500 GAUGE ASSY-OIL LEVEL (NOK) A12A <> 11140-H5001 15146-H5001 GUIDE TUBE 15146-H5002 GUIDE TUBE -0780 <> 15146-H5001 15146-H9801 GUIDE TUBE 0880- <> 15146-H5002

FWD

FWD A-series engines use a totally different dipstick.

F10 USA 11140-M3001 ASSY-GAUGE,OIL LEVEL -1076 11140-M4965 ASSY-GAUGE,OIL LEVEL 1076- Y 11140-M3001 11145-M3001 ASSY-GUIDE,OIL LEVEL -1076 11145-M4966 ASSY-GUIDE,OIL LEVEL 1076- Y 11145-M3001 11146-M3000 ASSY-SUPPORT,OIL LEV

N10 USA 11140-W6660 GAUGE-OIL LEVEL A15S 11140-W7000 GAUGE-OIL LEVEL A14S 11140-W7001 GAUGE-OIL LEVEL A14S <> 11140-W7000 15146-W7001 GUIDE-OIL LEVEL GAUGE A14S 15146-W6660 GUIDE-OIL LEVEL GAUGE A15S 15146-W6661 GUIDE-OIL LEVEL GAUGE A15S

Oil Level

Oil should be between H and L marks.

Marks are the same for early (H10) vs late (H50) gauges, even though the overall gauge length differs. That's because they use the same oil pan! The oil level from the bottom of the pan is what is important.

Datsun 1000

The Datsun 1000 type 180 dipstick appears to be about the same length as early A12

Uses a complicated multi-piece stopper with two o-rings. The rationalized A12 dipstick uses a one-piece rubber stopper with 3 sealing edges

Tube Removal

Use vice-grips and tap it up and out while twisting back and forth. Put a bolt in the end before gripping it to prevent tube collapse.

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)