|

Main Menu

Login

Fast Search Slow Search

Google Ad |

Browsing this Thread:

1 Anonymous Users

You can view topic.

You cannot start a new topic.

You cannot reply to posts.

You cannot edit your posts.

You cannot delete your posts.

You cannot add new polls.

You cannot vote in polls.

You cannot attach files to posts.

You cannot post without approval.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

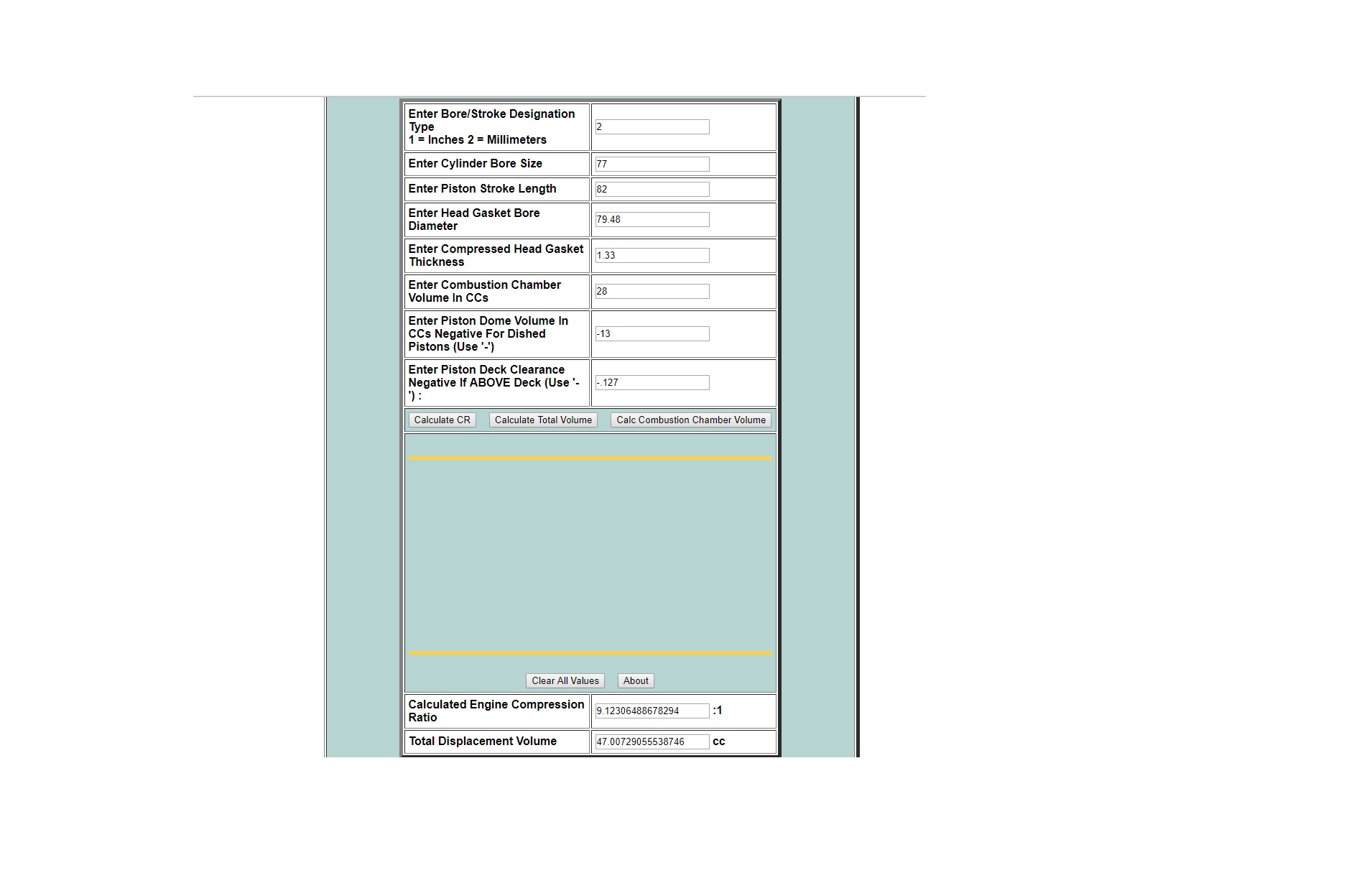

compression.jpg (168.16 KB)

compression.jpg (168.16 KB)

Transfer

Transfer