Moderator

Joined:

2001/5/3 7:04

From Kent, WA

Group:

Registered Users

Contentmaster

Usermaster

|

Hi Dave, for rusty bores, use steel wool and naval jelly to remove the rust If the bore then measures in-spec, go ahead and use it. If it doesn't clean up all the rust, go ahead a hone it

Use a flex-hone (ball-type hone) instead of a stone type hone. The re-check the bore and if it is still in spec you are good to go. If after honing it is now too large, you can either use a different block or rebore it for larger pistons. The advantage of overbore is that you get more HP than most other mods, for example adding compression. You can also upgrade to flat-top pistons at the same time for even more HP increase

If the flex hone doesn't clean it up use a regular stone type hone, The stone hone will remove more of the wall. This is a traditional hone, and usually this is fine for an overhaul, but it can be overdone and enlarge the cylinder too much, so just do it enough to clean it up then re-measure

For the newbies, honing mean finishing the cylinder walls to receive new rings:

* After a cylinder bore, to fine-smooth the walls out

or

* At an overhaul, to re-smooth the wall to correct minor issues -- for example to clean up very light rust. It is not designed to repair damaged walls. If there is pitting then a rebore is needed

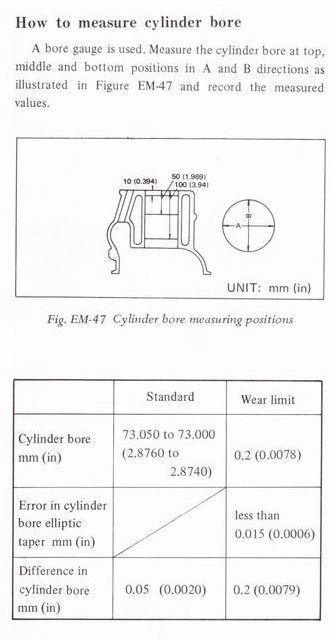

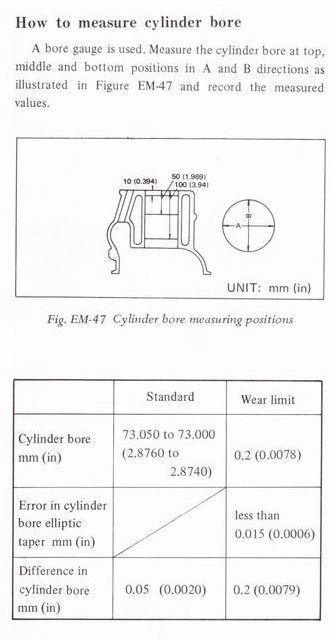

As always when rebuilding, first check the cylinder for trueness and straightness. If out-of-spec it will need to be re-bored if any measurement is larger than spec

Attach file:

EM-16 measuring cylinder bore.jpg (57.69 KB) EM-16 measuring cylinder bore.jpg (57.69 KB)

Posted on: 2018/5/1 8:14

|

Transfer

Transfer

EM-16 measuring cylinder bore.jpg (57.69 KB)

EM-16 measuring cylinder bore.jpg (57.69 KB)