|

|

Browsing this Thread:

2 Anonymous Users

|

|

kinda rant about instrumentation |

|

Just can't stay away

Joined:

2014/1/18 5:51

Group:

Registered Users

|

I have an A14, mostly stock, in an old Triumph Spitfire. It's about the same size as the original engine, but a lot lighter and more reliable. It's been solid for about 9 years, and I drive the car about 100km/week.

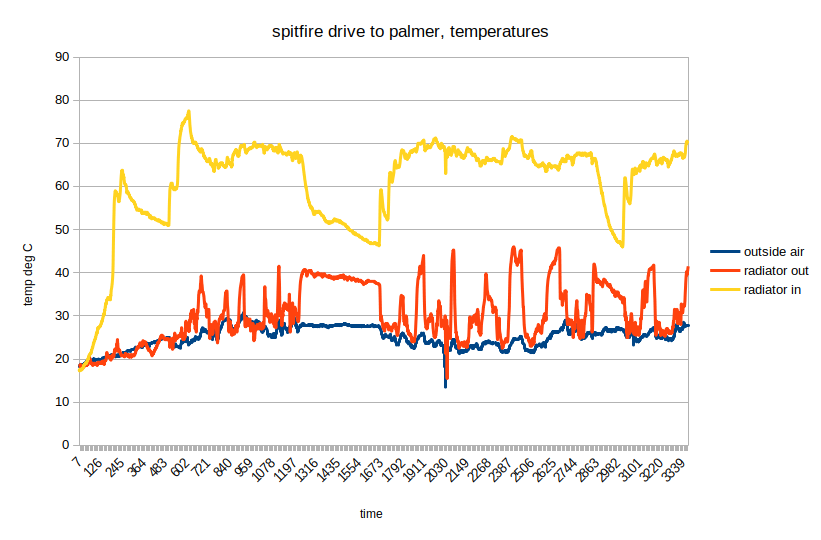

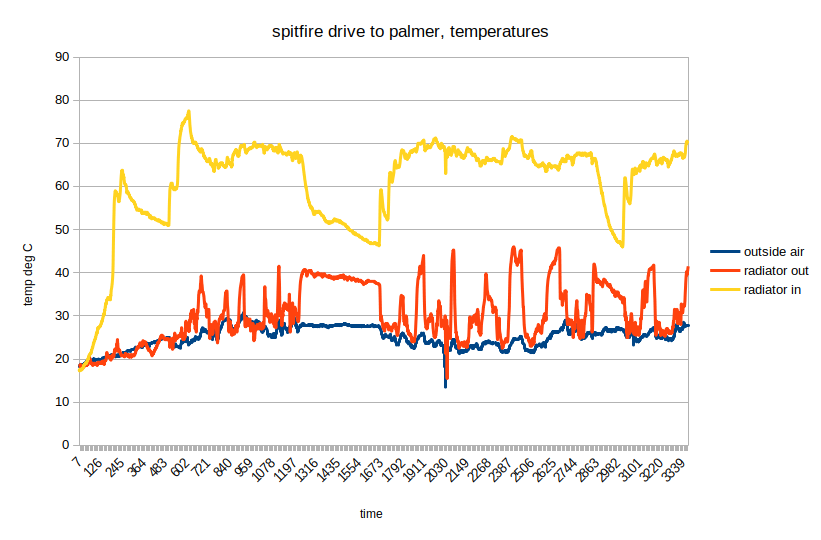

The Spitfire is a hot car. I donít mean like a hotrod. It is that too, but I specifically mean it is toasty. When I drive it in the winter at temperatures my Seattle friends claim donít actually exist, Iím pretty comfy except for the upper half of my head, and in August at noon itís like an oven, even with the top down and cruising along fast on the highway. The water temperature gauge reinforces this feeling: it regularly shows the engine water temperature hovering at 200-210 degrees F, and in the summer it goes right off the top of the scale. The thermostat is a 170F so in theory it should not be running anywhere nearly this hot. But maybe itís not enough radiator, or the airflow to it is terrible. (Itís sitting upright in the engine compartment with no ducting ahead/behind it, so itís plausible that the air going into the front is the air that just came out the back, recirculating.)

Iíd like to do a bunch of things to add some power to this engine, and that means I need more heat rejection, so I decided to instrument it to find out how well the radiator works. Whatís the air temperature right in front of it? How much cooling happens as water runs through it?

Well, I have an entire reel of thermocouple wire. Like 200 meters of it. So I can put thermocouples everywhere. And I did.

(I wrote a little arduino sketch that logs speed via gps and three channels of thermocouples, but the GPS device driver is too big to fit in my little 28K of flash, so all I get is three channels of thermocouples, logged, displayed, and some code to detect communication errors with sensors/storage and reinitialize everything.)

The thermocouples all say that itís about 10-20 degrees outside, when I start, and then the one on the radiator input, where the hot water from the engine enters, runs up to hang out at about 60C, with (in this run) a max of 77C. WAY less than the water temperature gauge says, and significantly below where the engine should be running. The water coming out of the bottom of the radiator is 30C. Thatís colder than my shower water. This engine should be running hotter, and this radiator will easily handle more aggressive ignition timing, fuel injection, and maybe some boost.

Thereís a cool plateau in the middle. Thatís where I stopped the car and left the logger running while I hiked into a park to play Ingress: without much air movement, just the fans, the exit water temp rose while the intake water temp gently dropped.

Attach file:

spitfire_radiator_temperatures_palmer_memoriai.png (64.52 KB) spitfire_radiator_temperatures_palmer_memoriai.png (64.52 KB)

Posted on: 5/1 4:15

|

|

|

|

|

Re: kinda rant about instrumentation |

|

Moderator

Joined:

2001/5/3 7:04

From Kent, WA

Group:

Registered Users

Contentmaster

Usermaster

|

10F degrees? It don't get that cold in Seattle except maybe once every 10 years I remember riding in a 1965 Spitfire over Siskiyou pass. It was freezing cold, but right in front of the dash it was toasty warm. I had to keep my arms away from the doors, where it was still cold. The top was not insulated Generally, a radiator don't need any fan shroud. The fan will pull air through the core, and when the car is moving, the movement forces air through the core even without a fan. Shroud ducting only increase this effect, it don't cause the cooling effect Even more important than a shroud is to seal any gaps between the core support and core

Posted on: 5/1 19:52

|

|

|

|

|

Re: kinda rant about instrumentation |

|

Just can't stay away

Joined:

2014/1/18 5:51

Group:

Registered Users

|

I've had the Spitfire out in -10F. That A14 chugs along like a champion. I'll post a picture of what I was playing with: I'd built a shroud system such that air into the radiator only comes from the (very very limited) grille area or underneath the front of the car. It works well, and I thought I needed it, but I don't currently. There's no core support at all. The core is sitting bolt upright like a tombstone, with a U-shaped support that bolts to the frame rails and a single support strut going into the frame so the support isn't purely cantilevered. That's why I was wondering if it had a recirculation problem. Maybe when it has fuel injection and 10psi of boost it'll need some more cooling.

Posted on: 5/2 3:04

|

|

|

|

|

Re: kinda rant about instrumentation |

|

No life (a.k.a. DattoMaster)

Joined:

2002/10/28 6:49

From under the Firmament LOL no twiglight effect BS

Group:

Registered Users

|

I made a custom perspex sunvisor that attached near top of screen to

deflect wind otherwise hitting top of my head on my old Triumph Herald.

I scored an old circular type heater aftermarket from the 60s it was

fitted to a Datsun 320 ute and as the little cast iron engine produced

plenty of heat, never had an issue driving in winter in the blue mountains,

which got just as cold as there.

Is the radiator sitting correct to the height of the engine? too low maybe?

I used the toyota red type radiator fluid religiously as well.

Honda civic alloy radiator from ebay also did the trick for cooling.

Sure copper/brass rads last 4ever yet alloy cools better for same form factor.

Posted on: 5/3 2:47

|

|

_________________

"Australia" is formed by all its geographically listed territories "including" Norfolk, Christmas & Cocos Islands. The word include excludes all else before it therefore you have no legal rights.

|

|

|

Re: kinda rant about instrumentation |

|

Moderator

Joined:

2001/5/3 7:04

From Kent, WA

Group:

Registered Users

Contentmaster

Usermaster

|

Copper is more efficient at shedding heat than aluminum. The reason all the aluminium aftermarket radiators work so well is they are 2x or 3x thick. If you made a copper/brass radiator that way, we wouldn't be able afford it. Even the 1x copper radiator costed $200-$300, and that was 20 years ago when the alloy version was only $100

Posted on: 5/3 7:38

|

|

|

|

|

Re: kinda rant about instrumentation |

|

Just can't stay away

Joined:

2014/1/18 5:51

Group:

Registered Users

|

Mine had the original copper/brass radiator, and it was leaking quite a bit because of corrosion. I got a cheap aluminum one. It's worse in a lot of ways, but it's better in that I can cut off the hose spigots and weld blanks over them, and then put in new ones where the Datsun engine wants them, and add a drain plug. The car's a lot easier to work on now and I can use standard Datsun 1200 coolant hoses rather than having to cobble together coolant hoses from SUV's with little pipe sections between them to make the U-bends that a reversed coolant hose location setup requires.

Posted on: 5/3 21:42

|

|

|

|

|

Re: kinda rant about instrumentation |

|

Moderator

Joined:

2001/5/3 7:04

From Kent, WA

Group:

Registered Users

Contentmaster

Usermaster

|

haha! well said

How do you weld the aluminum?

Posted on: 5/4 0:48

|

|

|

|

|

Re: kinda rant about instrumentation |

|

Just can't stay away

Joined:

2014/1/18 5:51

Group:

Registered Users

|

I have a TIG and while I'm not bicycle frame good, I'm good enough to weld leak-free. It just isn't pretty. It was a LOT of welding, though: remove drain from one side, put it in on the other side (so it clears the radiator support), and move both spigots and patch the holes.

I'm glad it had the overflow hardware already attached in the right place. I don't think I could do that.

Posted on: 5/4 3:24

|

|

|

You can view topic.

You cannot start a new topic.

You cannot reply to posts.

You cannot edit your posts.

You cannot delete your posts.

You cannot add new polls.

You cannot vote in polls.

You cannot attach files to posts.

You cannot post without approval.

|

spitfire_radiator_temperatures_palmer_memoriai.png (64.52 KB)

spitfire_radiator_temperatures_palmer_memoriai.png (64.52 KB)

Transfer

Transfer