| Revision as of 07:44, 1 May 2018 ddgonzal (Talk | contribs) (->Installing) <- Previous diff |

Current revision ddgonzal (Talk | contribs) (->Installing) |

||

| Line 93: | Line 93: | ||

| = Installing = | = Installing = | ||

| - | When overhauling the engine due to low compression or excessive blowby, new piston rings are installed to bring it back to specification. Normally a re-bore and new pistons are not required -- it is not part of an overhaul. | + | When overhauling the engine due to low compression or excessive blowby, new piston rings are installed to bring it back to specification. Normally a re-bore and new pistons are not required -- it is not part of an [[overhaul]]. |

| - | Measure the cylinder bore with micrometer to ensure it is within wear limits. You can do an initial measurement before removing the pistons. If it is in spec, remove the pistons are do a final measurement check. | + | Measure the cylinder bore with micrometer to ensure it is within wear limits. You can do an initial measurement before removing the pistons. If it is in spec, remove the pistons then do a final measurement check. |

| If there is a perceptible ridge at the top of the cylinder -- if your fingernail catches on it -- then use a ridge reamer before removing the piston assembly. | If there is a perceptible ridge at the top of the cylinder -- if your fingernail catches on it -- then use a ridge reamer before removing the piston assembly. | ||

| Line 104: | Line 104: | ||

| == Measuring Cylinder == | == Measuring Cylinder == | ||

| - | From the A12 [[Factory Service Manual]]<blockquote>[Using a bore gauge,] measure the cylinder bore at top, middle and bottom positions</blockquote> | + | From the A12 [[Factory Service Manual]]<blockquote>[Using a [[wikipedia:Bore_gauge|bore gauge]],] measure the cylinder bore at top, middle and bottom positions</blockquote> |

| TOP: 10mm down from deck surface | TOP: 10mm down from deck surface | ||

| Line 161: | Line 161: | ||

| * After a cylinder bore, to fine-smooth the walls out | * After a cylinder bore, to fine-smooth the walls out | ||

| or | or | ||

| - | * At an overhaul, to re-smooth the wall to correct minor issues -- for example to clean up very light rust. It is not designed to repair damaged walls. If there is pitting then a rebore is needed. | + | * At an [[overhaul]], to re-smooth the wall to correct minor issues -- for example to clean up very light rust. It is not designed to repair damaged walls. If there is pitting then a rebore is needed. |

| If the cylinders measure in spec with no visible damage, honing should not be done. De-glazing is not necessary. The rings will last longer and make more power without honing -- a smooth cylinder is properly oiled by the piston finish. The crosshatch pattern resulting from honing is however required to for new-boring break-in, but not required when fitting rings to a previously good running cylinder. | If the cylinders measure in spec with no visible damage, honing should not be done. De-glazing is not necessary. The rings will last longer and make more power without honing -- a smooth cylinder is properly oiled by the piston finish. The crosshatch pattern resulting from honing is however required to for new-boring break-in, but not required when fitting rings to a previously good running cylinder. | ||

| Line 172: | Line 172: | ||

| <br>{{UploadPost|11671_52d34bc71fff2.jpg|450120}} | <br>{{UploadPost|11671_52d34bc71fff2.jpg|450120}} | ||

| - | If the flex hone doesn't clean it up use a regular stone type hone, The stone hone will remove more of the wall. This is a traditional hone, and usually this is fine for an overhaul, but csn be overdone and enlarge the cylinder too much, so just do it enough to clean it up then re-measure | + | If the flex hone doesn't clean it up use a regular stone type hone, The stone hone will remove more of the wall. This is a traditional hone, and usually this is fine for an [[overhaul]], but can be overdone and enlarge the cylinder too much, so just do it enough to clean it up then re-measure |

| [[Category:Engine Mechanical]]{{End}} | [[Category:Engine Mechanical]]{{End}} | ||

Current revision

Standard equipment was Cast Iron rings, which work well and seal good -- you can't go wrong with cast iron rings. Chrome rings are available, but need a finer cylinder hone.

Contents |

Overview

It is not mandatory to hone a block when your using new piston rings. As long as you can visibly see the crosshatch, then you will not experience any problems. As always when rebuilding, check the cylinder for trueness and straightness (it may need to be re-bored even if the hone finish is good).

Ring Type A12/A13, early A14: 2.0 mm, 2.0 mm, 4.0 mm oil A15/A14 late: 1.2 mm, 2.0 mm, 4.0 mm oil

Genuine Nissan cast iron rings by Riken (Rik-Vent rings)

For street engines, it is recommended to use stock-spec cast iron rings

- Cast iron rings seal minor cylinder imperfections, resulting in an excellent seal

- Cast iron rings need no special break-in

- Cast iron rings are the least expensive

- Cast iron rings last around 150,000 miles/240,000 kilometers

If you are racing you might want to try other rings. For example chrome-ring require extra-fine honing and straighter cylinder bores.

Part Numbers

B110 A12 12033-H6201 SET-RING PISTON STD A12 > 12033-H6200 > 12033-H1002 for oversizes, see Piston, Crank & Rod Part Numbers * Goetze/Federal-Mogul 08-291400-00 * NPR SWN30026ZZ > 12033-H6211 * Hastings 2C6714 Hastings 6714 or 2C6714 Chrome $37 set * Nissan A12 * Mitsubishi 4G33/4G30 * Replaces: 12033-01302/12033-01303, 12033-10600/12033-10601, 12033-10800 12033-13900/12033-13901, 12033-19100, 12033-B3040 (J13)

B210 with A13 12033-H6200 SET-RING PISTON STD <> 12033-B3040 12033-B3040 SET-RING,PISTON (STD SIZE, RIK-VENT)12K * also used by Datsun 520 with J13 engine

C20 12033-13201 SET-RING, piston (RIK-VENT) 12033-H1101 (RIK-VENT) > 12033-13201 12033-13203

A10 with A14 12033-H7200 -8003 12033-H9910 8004- <> 12033-H7200

1978-1979 GFU, CAN A15 1979-1980 12033-H7680 SET-RING PISTON STD GFU 0877- 12035-H7680 SET-RING PISTON (0.5 MM OVERSIZE) GFU 0877- 12037-H7680 SET-RING PISTON (1.0 MM OVERSIZE) GFU 0877-

* B210 EXCEPT 1978 GFU * F10 * B310 USA -0779 [1979 model year] * B310 CAN 0879-0880 [1980-1981] 12033-H7200 STD 12035-H7200 0.5 MM OVERSIZE 12037-H7200 1.0 MM OVERSIZE

1980 * B310 0879-0780 12033-H9900 STD <> 12033-H9910

1981-1982 A14/A15 * B310 USA 0880- * B310 CAN A14 12033-H9800 STD <> 12033-H9810

12033-H8915 * A15 1279-0780

Interchange

A12 MAZDA 1976-1978 * GLC 1977-1978 L4-1272cc 1.3L 2 BBL Vin TC * MIZER 1976-1977 L4-1272cc 1.3L 2 BBL Vin TC NISSAN/DATSUN 1967-1974 * B110 1200 1971-1973 * B210 1974 L4-1288cc 1.3L 2 BBL Vin A13 * PICKUP 520 1967-1968 L4-1299cc 1.3L 2 BBL Vin J13 * PICKUP 521 1968-1969 L4-1299cc 1.3L CARB Vin J13

A12A Standard Size Piston Rings - Cast Iron Rings; Bore 75mm"; 8-2.0mm Comp and 4-4.0mm Oil Rings. * SEALED POWER #E-362X.STD, 9469X. * Hastings #2M-6813 Fits: * 1979-1982 Datsun/Nissan 210 4 cyl. 1.2L 1237cc A12A engine * 1971 & Up Mazda 4 cyl. 1.5L 1484cc UA engine * 1968-1969 Toyota Corolla 4 cyl. 1.1L 1077cc KC engine * 1969-1979 Toyota Corolla 4 cyl. 1.2L 1166cc 3KC engine * 1981-1982 Toyota Starlet 4 cyl. 1.3L 1290cc 4KC engine

Installing

When overhauling the engine due to low compression or excessive blowby, new piston rings are installed to bring it back to specification. Normally a re-bore and new pistons are not required -- it is not part of an overhaul.

Measure the cylinder bore with micrometer to ensure it is within wear limits. You can do an initial measurement before removing the pistons. If it is in spec, remove the pistons then do a final measurement check.

If there is a perceptible ridge at the top of the cylinder -- if your fingernail catches on it -- then use a ridge reamer before removing the piston assembly.

As always when rebuilding, first check the cylinder for trueness and straightness:

- If out-of-spec it will need to be re-bored if any measurement is larger than spec

- If in-spec and no damage is visible, no honing is required, just put the new rings in

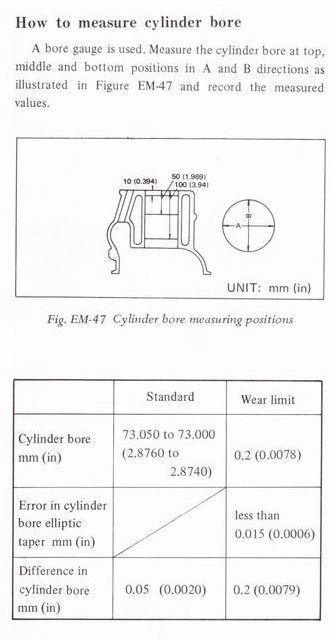

Measuring Cylinder

From the A12 Factory Service Manual[Using a bore gauge,] measure the cylinder bore at top, middle and bottom positions

TOP: 10mm down from deck surface MIDDLE: 50mm down BOTTOM: 100mm down

Bore: 73.000-73.050 mm Taper (Bottom-Top) 0.015 mm maximum Difference (A-B) 0.050 mm maximum

Measuring Gap

Measure the ring gap with the ring fitted into bore and pushed down -- according to Nissan -- at POST the bottom of the traveled part of the cylinder. Push the ring down using an upside-down piston to square it to the cylinder. Do this with lightly oiled cylinder so that the ring & piston can slide

A12 Gap Wear Limit (may be reused if less than limit) 1.0mm (0.0394"}

A12 (73mm bore) new ring gap Top Ring 0.2-0.35mm (0.0138") 2nd Ring same as Top ring Oil ring 0.3-0.9mm (0.0118-0.0354")

A14/A14 (76mm bore) Top Ring maximum 0.014" gap 2nd Ring maximum 0.012" gap Oil ring 0.0118-0.0354" gap

If you have to jam the feeler gauge in, use the next smaller gauge. It should fit in with only a slight drag. If it is tight, use the next smaller gauge.

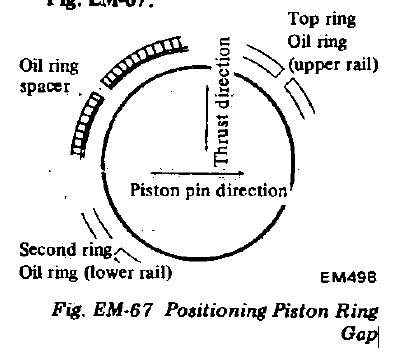

Ring Positioning

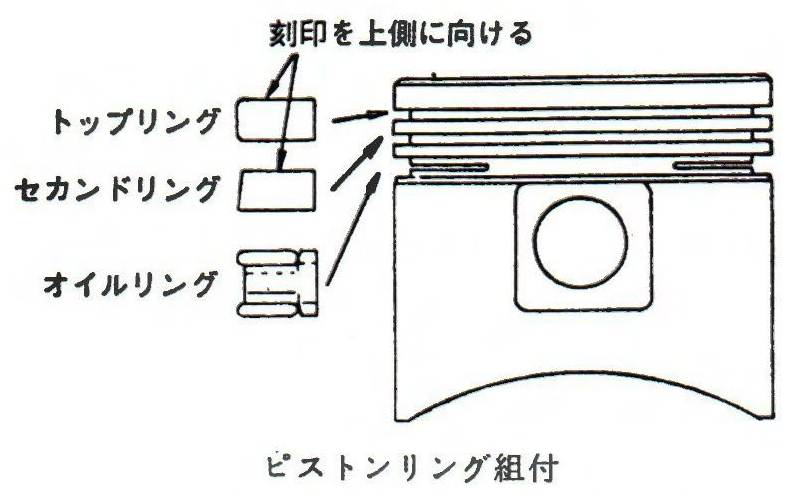

It is critical to install the rings right side up

The rings must be turned relative to the bore. There is several ways to "do it right", and so you'll find different diagrams. All the ways involve staggering the gaps.

The Datsun 1200 factory service manual (1973 edition) doesn't seem to cover this, you would normally follow the ring manufacturer's instructions. The Nissan B310 FSM has a circa 1980 recommendation. Your ring manufacturer may have a slightly different suggestion. Either way will be correct.

The thrust side of the engine (Major Thrust Side) refers to the side hit hardest during the power stroke (the other side is the Minor Thrust side). This is also why pistons are marked with an 'F' (for front) -- so that the piston's major thrust side will be installed correctly.

Oil Ring is composed of three pieces

- Discussion: Piston ring gap placement

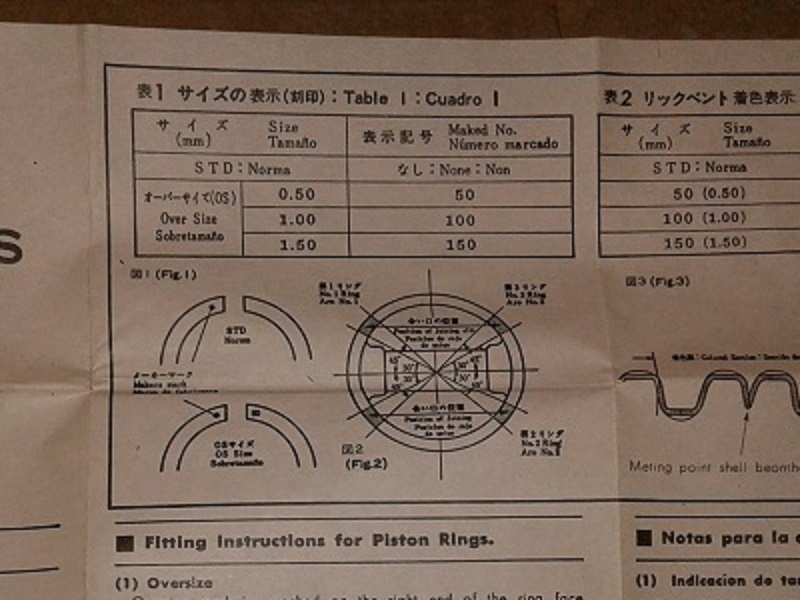

Nissan genuine ring instructions

Honing

Honing mean finishing the cylinder walls to receive new rings:

- After a cylinder bore, to fine-smooth the walls out

or

- At an overhaul, to re-smooth the wall to correct minor issues -- for example to clean up very light rust. It is not designed to repair damaged walls. If there is pitting then a rebore is needed.

If the cylinders measure in spec with no visible damage, honing should not be done. De-glazing is not necessary. The rings will last longer and make more power without honing -- a smooth cylinder is properly oiled by the piston finish. The crosshatch pattern resulting from honing is however required to for new-boring break-in, but not required when fitting rings to a previously good running cylinder.

For rusty bores, use steel wool and naval jelly to remove the rust If the bore then measures in-spec, go ahead and use it. If it doesn't clean up all the rust, go ahead a hone it

Use a flex-hone (ball-type hone) instead of a stone type hone. The re-check the bore and if it is still in spec you are good to go. If after honing it is now too large, you can either use a different block or rebore it for larger pistons. The advantage of overbore is that you get more HP than most other mods, for example adding compression. You can also upgrade to flat-top pistons at the same time for even more HP increase

If the flex hone doesn't clean it up use a regular stone type hone, The stone hone will remove more of the wall. This is a traditional hone, and usually this is fine for an overhaul, but can be overdone and enlarge the cylinder too much, so just do it enough to clean it up then re-measure

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)