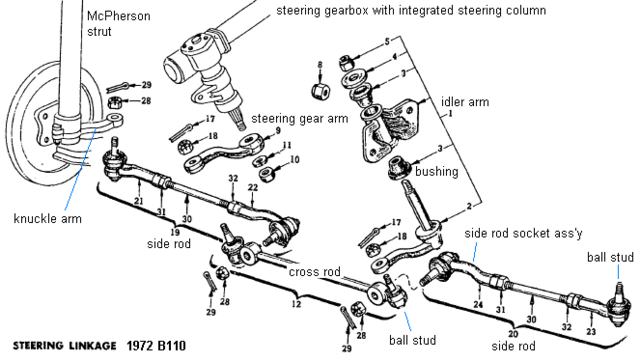

The Datsun 1200 uses a traditional recirculating-ball Steering Gearbox with rear steer (behind-the-axle) linkage.

Contents |

Overview

Notice how the left and right steering side rods are the same length, and in the same plane, as the lower control arms. This is important for proper steering geometry

Terminology

The six ball studs have a Filler Plug on the bottom of each. Replace it with a grease fitting and fill it during each periodic "lube, oil and filter".

- 1. Idler Arm. This bolts to the subframe rail on opposite side from the steering gearbox

- 9. Steering Gear Arm, a.k.a. "Pitman arm"

- 19,20. Side Rod, a.k.a. "tie rod". Left and right hand differ

- 12. Cross Rod, a.k.a. "drag link" or "center link"

- 21, 22, 23, 24. Side Rod Socket Ass'y a.k.a. "tie rod ends". There are four separate parts with left and right-hand threads. Each "socket" has a "ball stud", which is similar to a Ball Joint.

Inspection

You cannot tell by looking if the rod-ends or ball joints are worn. Anything more than 1" play in the steering wheel indicates loose steering.

Of course you'll want to confirm that the steering linkage is tight, because that's usually where the play is. The tie-rod (side rod) ends, ends of the drag link (cross rod), and particularly the idler arm should be inspected.

Easiest way to check for play in the linkage is with the car over the ground/over pit, get some one to wobble the steering wheel left to right and hold each tie rod joint in between your fingers, you should feel no play in these joints...

You can check the steering linkage as follows:

- lie on the ground near the driver's side door, looking at the underside of the car

- reach up and wiggle the steering wheel back and forth (with the door open)

- watch to see if any of the rods move independent of each other. If they do, the rod ends need replacement.

- the steering knuckle, and thus tires, should move with the tie-rods. If a rod moves, but not the tyres, the linkage is worn at that point

- the idler arm should NOT move up and down, only rotate. Replace Idler Arm bushings if ANY up-and-down motion is detected

This can be easier if a mate handles the wheel, leaving you free to inspect the underside, but it can be done without an assistant.

To double check any of the rod ends and idler arm, jack up the wheels and securely block the car, then wiggle the rod end ends forcefully by hand. There should be no play; they are supposed to rotate, but not move end-to-end.

Finally, if in doubt, disconnect the rod-ends, they should move with a firm but smooth drag as you rotate them. If they flop around, they are worn out.

Power Steering

Separating Ball-stud from Linkage

Separating the Steering Linkage for tie-rods, cross-rod, steering arm, knuckle arms or ball joints. To separate a rod-end/balljoint/ballstud, use one of these methods:

- Pickle fork and hammer

- Tierod-end joint puller

- Two-hammer method

- Prybar and hammer

CAUTION Never hammer on the threaded portion!

Datsun recommended the two-hammer method. Pickle fork is perhaps easiest but may damage the joint boot. Puller method is very nice.

WARNING Heating forged steering components is a VERY large no-no

Steering Gearbox Arm

Use the hammer methods or a gear puller.

Do not place a piece of pipe or wood on the steering rod and smack it hard with a big hammer. This can bruise/dent the worm in the steering box and compromise the box's smooth operation.

Two Hammer Method

- Remove the cotter pin & loosen the castle nut as far as the end of the ball-stud. This will hold the part from dropping all the way when the joint is popped apart.

- Hold a large hammer (e.g. 8# sledge) against one side of the part with the hole, and smack the other side with a 2nd hammer. The joint will pop out of the hole.

The first hammer is to absorb the blow so the part doesn't move.

NOTE: You have to smack it very hard while holding the stationary hammer at the same time AND not hit any other body or suspension parts. To make it easier, have an assistant hold the stationary hammer.

Sometimes people are not successful, usually because the hammer blow is not square to the stud axis and the energy is lost. But it will come out, regardless of condition, age, what-have-you, when done correctly. This is the method master mechanics use.

Pickle Fork

NOTE: Pickle fork may damage the joint boot. Great way to remove old bad parts, but the other methods are suggested for reusing the parts.

Pickle fork (wedge) fits many sizes of joints. For a Datsun, a medium size pickle fork is about right.

- Remove the cotter pin & castle nut

- Insert the fork between the two parts

- Whack the hammer very hard with big hammer. Use at least an 8# sledge. Better is a 12# or 16# hammer.

TIP: If possible, insert the hammer inline with the steering linkage, so that your hammer blow doesn't deflect the linkage sideways. Moving the steering wheel first will help line up the linkage to where you can hit it straight on.

Ball Stud Puller

You can use any small gear puller. A puller fits only certain sizes, but doesn't damage the grease covers. If using a generic puller, make sure the shaft when turned does not damage the ballstud threads.

- Remove the cotter pin & loosen the castle nut as far as the end of the ball-stud.

- Insert puller into correct position

- Turn puller nut with wrench or socket until the joint pops apart

- Remove castle nut fully

Lever and Hammer

- remove the split pin and nut

- Insert the lever (prybar, crowbar, etc.) to apply a medium pressure on the two pieces, as if prying them apart. But the leverage is only to apply pressure, NOT to actually separate them.

- While keeping pressure on the parts, using two hammers, hit opposite sides of the hole simultaneously. You don't need to use Big Hammers.

What you are doing is deforming the hole out of round for just a second which breaks the tapers bond from being jammed together, this will spit the ball stud off. You dont need to pound very hard, just keep tapping away.

Idler Arm

Cross Rod

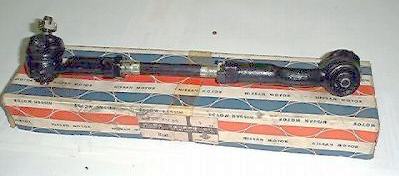

The Cross Rod is also known as center link or drag link. It includes two ball stud joints which can wear out if not regularly lubricated.

RHD

48560-H1000 ROD ASS'Y-CROSS JDM B110, B120 (all years)

RHD B110 top, B210 bottom:

NOTE: B210 RHD bar can be used on B110 RHD

NOTE: B210 RHD bar can be used on B110 RHD

RHD measurements

548 mm & 479 mm

Other RHD

B10 48545-18001 BUSHING-idler shaft

PB110

48560-H2500 ROD ASS'Y-CROSS PB110, PB210

B210

48560-H5025 ROD ASS'Y cross steering RHD JDM

RHD B210 bottom, B110 top:

B210 has a kink for clearance

B210 has a kink for clearance

B310 (and A10) 48560-W5025 ROD ASSY-CROSS JDM B310, A10

クロスロッド

LHD

B110 48560-H1600 ASSY-CROSS ROD STEERING USA B110 * ACDelco 45B1035 or 88911087 $99.97 Rockauto.com

B210 48560-H6200 ASSY-CROSS ROD LHD USA Rockauto.com

B310 - straight or kinked 48560-W5725 ROD ASSY-CROSS,STEERING North America B310, A10 * Moog ES2450* Moog NI-DL-2450

* 48560-W5700 - straight

Side Rods

Side Rod also known as Tie Rod, consists of a threaded shaft and two ball-socket "ends".

Side Rods * Inner thread: M14 * Stud thread: M10, with 17mm hex castle nut * Stud cone: 1/10 Hole in the cross rod goes from 11m to 13mm and is 11.5mm thick

Side Rod Ends also known as Tie Rod Ends

Inspect, and replace if bent or if ball-socket is loose

Obviously bent!

B110, B120 48510-H1025 ROD ASSY-SIDE RH 7210- $134.33 USD [tie rod ends not available separately] 48630-H1025 ROD ASSY-SIDE LH 7210- $134.33 USD [tie rod ends not available separately] 48510-H1002 ROD KIT-side (R.H.) (from '72-10) 48630-H1002 ROD KIT-side (L.H.) (from '72-10) 48510-H1001 ROD ASS'Y-side (R.H.) (up to '72-9) $80.28 USD 48630-H1001 ROD ASS'Y-side (L.H.) (up to '72-9) 01227-00011 NUT (4) -8503 01227-00091 NUT (4) 8504- 08921-32010 PIN-cotter (4)

PB110 48510-A0600 ROD ASS'Y-side (R.H.) (up to '72-10) 48630-A0600 ROD ASS'Y-side (L.H.) (up to '72-10) 48510-U0100 ROD ASS'Y-side (R.H.) (from '72-11) 48630-U0100 ROD ASS'Y-side (L.H.) (from '72-11) 01272-00031 NUT (4) PB110 or 89-11042-1 08901-32510 PIN-cotter (4) PB110, PB210

PB210 48510-H5800 ROD ASS'Y-side (R.H.) 48630-H5800 ROD ASS'Y-side (L.H.) 01227-00061 NUT (4) PB210 08901-32510 PIN-cotter (4) PB110, PB210

NOTE: Cotter pin & Nut are same as used with Steering Gear Arm & Idler Arm (total 6 per car)

Datsun B10 (1000)

Type 180 parts

Side Rod Bar

Aka Tie Rod End Adjusting Sleeve, Tie Rod Adjuster, or Steering Linkage Adjuster. The flat in the middle is for a wrench to turn it while in place. The ends are left- and right-threaded, so that turning both rods equally adjusts toe-in.

Nissan 48512-A0600 BAR-SIDE ROD (2) PB110 $8.33 USD 48512-H5800 BAR-SIDE ROD (2) PB210 $6.27 USD

B110/B120 - RHT M14 x 1.5 by LHT M14 x 1.5 48512-H1001 BAR-SIDE ROD (up to '72-9) (2) * ACDELCO 45A6021 * GM 88910767 * Raybestos 4251021 * 012-1100011 / 01211-00011 NUT-lock, side rod (R.H.) (2) $1.10 USD [08911-3441A] * 012-1100021 / 01211-00021 NUT-lock, side rod (L.H.) (2) $1.60 USD

Interchange: B110 1971-1973 B210 1974-1978 200SX 1977-1979 510 1968-1973 610 1973-1976 710 1974-1977

TRW/MOOG ES458S * 48512-H1001 * 48512-H5800 * 48512-A0600 6.625" Length 510/610/710/S110/HB210.USA Raybestos 4251021 DEEZA NIJ604

NOTE: Bar is not listed as a separate part in later catalogs (after 1975)

W50 (B310/A10) Rare Parts 27303 Length: 179mm (7.062") Thread Size: M14 x 1.50

Inner Ends

Inner ends are curved

67 mm high 180 mm long M14 inner thread M10 stud thread

Inner RIGHT 48521-H1001 ASSY-SOCKET SIDE ROD RH INNER * McQuay-Noriss ES2620X * Raybestos 4011324 * ACDELCO 45A0324 or 88910158

Inner LEFT 48641-H1001 ASSY-SOCKET SIDE ROD LH INNER * Raybestos 4011327 * ACDELCO 45A0327 or 88910161

Outer Ends

Outer ends are straight, and have LH and RH threads.

67 mm high 79 mm long M14 inner thread M10 stud thread

Outer RIGHT - FEMALE RHT M12 x 1.5 x 79mm long 48520-H1001 ASSY-SOCKET SIDE ROD RH OUTER $59.80 USD * 555 SE-4091R * TRW ES488L -0772 * Raybestos 4011167 * ACDelco 45A0167 or 88910001 $18.94

Outer LEFT - FEMALE LHT M12 x 1.5 x 79mm long 48640-H1001 ASSY-SOCKET SIDE ROD LH OUTER $59.80 USD * 555 SE-4091L * TRW ES488R -0772 * Raybestos 4011168 * ACDelco 45A0168 or 88910002 $18.95

PB110/PB210/LB210/510/610/710/S10/C120 - M14 x 1.5 x 110mm long 48520-U0100 SOCKET ASS'Y-side rod outer (R.H.) (from '72-11) PB110, PB210 $57.33 USD * superceded 48520-A0600 SOCKET ASS'Y-side rod outer (R.H.) (up to '72-10) PB110 48640-U0100 SOCKET ASS'Y-side rod outer (L.H.) PB210 $57.33 USD * NOTE: PB110 L.H. not listed.

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)