|

|

Browsing this Thread:

1 Anonymous Users

|

|

racetech's 1200 SR20VE Project |

|

Home away from home

Joined:

2009/4/16 10:37

From Cape Town, South Africa

Group:

Registered Users

|

4 February 2010 - Datto Purchased and parts transported homeBought an ex project 1200 Deluxe from a bloke that gave up on the whole restoration idea. Received the body with only front struts an a diff, the rest was in boxes. Work started out slow but starting to take shape. Basic Idea, put bigger motor and gearbox in it, new independent rear suspension using the 3.9:1 BMW E30 limited slip diff, coil overs all round, roll cage, FIA approved seats and harnesses to be able to compete in All Tar Rally for a start and gymkhanas. This will be the basic idea, the list will grow as things start to come together. It will replace the ute, rust is taking over and need a little more space to move seats further. Now all the questions start and the jigsaw puzzle to get all the parts back together.              The parts I purchased with the vehicle was the Datto's parts and a lot of parts from a stripped 1200 GX. This included spare axles, spare motor, doors and way to much to include in this list, trust me there is a lot of parts from a generation that is almost forgotten. It took me nearly 2 weeks after work to organize and pack all the parts in boxes for storage.

Posted on: 2010/3/30 11:44

Edited by racetech on 2011/11/17 15:27:35

Edited by racetech on 2011/11/17 15:37:00

Edited by racetech on 2011/11/17 15:40:42

Edited by racetech on 2013/12/24 6:53:57

|

|

|

|

|

Re: racetech's 1200 SR20VE Project |

|

Home away from home

Joined:

2009/4/16 10:37

From Cape Town, South Africa

Group:

Registered Users

|

Car went in for a respray, it is know an off white, previous colour was a ugly cream.

Cleaned the front and rear wheel arches, never in my live was i more dirty than after this, used a wire brush and a die grinder to get it clean, painted it with a grey enamel paint.

Busy removing all the sound denoting to discover hidden rust and to be able the paint the interior.

Bought a new right and left fender, lower apron and two front window rubbers. Will be using the second one for the rear window, just need to cut in smaller as we do not get the rear window rubber anymore.

Currently busy resembling the doors.

Posted on: 2010/3/31 10:57

|

|

|

|

|

Re: racetech's 1200 SR20VE Project |

|

No life (a.k.a. DattoMaster)

Joined:

2004/7/15 12:10

From Adelaide, Australia

Group:

Registered Users

|

Sounds like an interesting project, maybe you can order a rear screen rubber from australia, scotts auto rubbers make one, also I have a number for another guy that made mine without the chrome strip channel so it looks cleaner.

pm me if you want more info on the rubbers!

Posted on: 2010/3/31 11:02

|

_________________

cheap + fast = disaster fast + reliable = expensive cheap + reliable = stock IPRA Build

|

|

|

Re: racetech's 1200 SR20VE Project |

|

Home away from home

Joined:

2009/4/16 10:37

From Cape Town, South Africa

Group:

Registered Users

|

Thanks Whitesedan for the info, if my plan does not work I'll get back to you on that one.

Posted on: 2010/4/2 9:28

|

|

|

|

|

Re: racetech's 1200 SR20VE Project |

|

No life (a.k.a. DattoMaster)

Joined:

2003/11/28 9:12

From South Africa, Bloemfontein

Group:

Registered Users

|

I got all the rubbers for my Sedan from Pro Auto Rubber here in Bloem.

They are national. Just look in the back of CAR magazine.

Posted on: 2010/4/6 10:36

|

|

_________________

1977 Datsun 1200GX

|

|

|

Re: racetech's 1200 SR20VE Project |

|

Home away from home

Joined:

2009/4/16 10:37

From Cape Town, South Africa

Group:

Registered Users

|

16 April 2010 - Datto moved to a bigger shedI got my father interested in the idea of building a old school racing car and he made a little space in his workshop. The only down side to this arrangement is the fact that I can only go and work on it over weekends as it is about 110km's from my residence in Cape Town.     After a lot of home work, I decided to not go ahead with a full race build A15 motor, it was just not a viable option anymore as I'm allowed to use a 2.0lt engine in my class. The race motor would be a bugger to drive around town as this vehicle must be road legal and be able to travel on public roads. After some more consideration and the fact that I need to cut away the old floors in the car and replace them, why not fit a bigger motor and stronger gearbox. More power for less money, now this can be argued, but in the long run I do believe it will be a cheaper option. A friend, mentioned the one day that a SR20 motor would be a good option, but specifically the VVL (Nissan Ecology Oriented Variable Valve Lift and Timing) motor. I do not know if I need to be angry or over joyed about the fact that he mentioned this to me, started reading and after a week or two was sold on the idea that my datto will be fitted with some serious Nissan power. Stephin put me in contact with Hanief Parker that sell these units in Cape Town, another person that I think I should hit with a brick or thank for providing the excellent info and tips regarding anything Datsun/Nissan to me. If it wasn't for these two people, I would still be trying to figure out what I can do to a A15 motor. I purchased a SR20VE, I think since that day I have spend more time on the phone and in his shed than I have done with my girlfriend, always willing to help and source some parts or a way to get something done.  The existing rear wiring loom of the datto was converted to enable the rear lights to work when towed on a A Frame. My Father helped to build a front bumper to mount the A Frame. My brother helped me to get the whole load organized. This was one heavy load for the bakkie, SR20VE on the back and the Datto on a A Frame following and Franschhoek Pass between us and the new shed. Everything went fine and on arrival at my parents home we started unloading and making plans to get it mounted.         Did not take me long to get the motor stripped to only the essentials and cleaned up. Started the trial fitting of the motor in the small engine compartment, right from the get go it was apparent that either the distributor and VVL controller will need to be relocated or the firewall modified.

Posted on: 2010/7/6 8:16

Edited by racetech on 2010/7/6 10:06:49

Edited by racetech on 2013/12/24 6:52:29

|

|

|

|

|

Re: racetech's 1200 SR20VE Project |

|

Home away from home

Joined:

2009/4/16 10:37

From Cape Town, South Africa

Group:

Registered Users

|

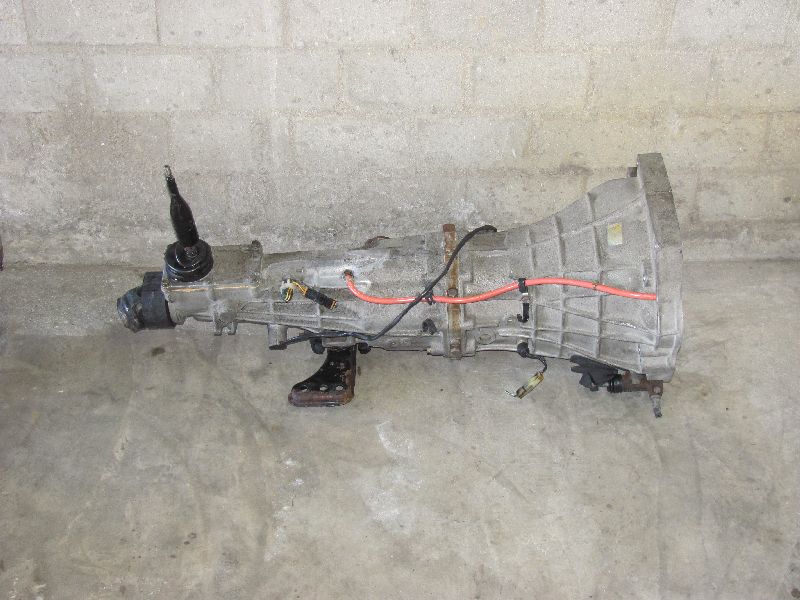

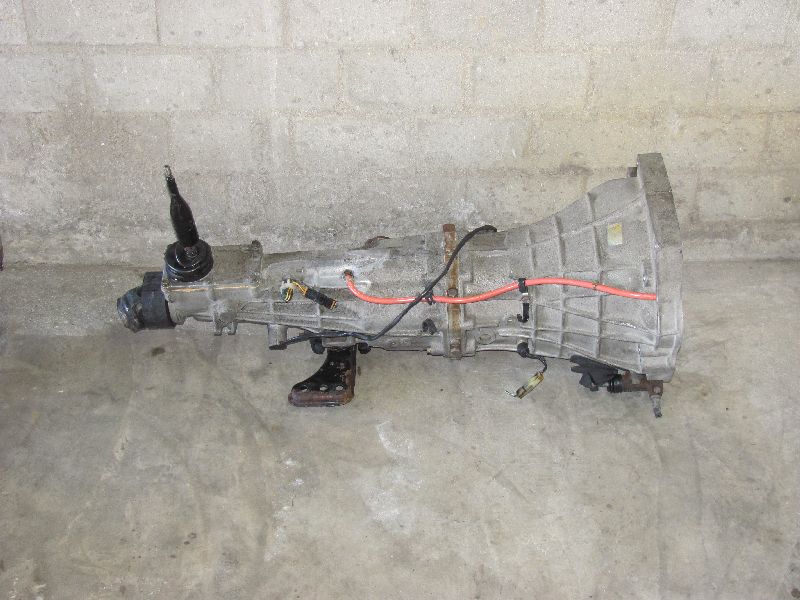

21 April 2010 – Gearbox sourced It did not take a lot of rocket science to decide on the gearbox, the easiest would be to use the Nissan S14 box so called FS5W71C. Only downside to the specific box would be that the gearbox tunnel would need to be modified, but then it would have to be done for all bigger boxes.  Diff that would be used is a BMW E30 3.64 LSD. The thought of building a Independent Rear Suspension for a 1200 got the better of me, especially in South Africa were sourcing a LS for our Borg Warner diffs is virtually impossible.  Decided on using the S14 RWD flywheel with minor modifications to get the FWD starter to align correctly with the ring gear teeth. Using the FWD starter helps a lot, no cutting of the VE block. Then the S14 RWD upper oils pan was sourced, this provides more space between the motor and the frame of the 1200. The biggest reason for this is the fact that 4 more bolts line up. Thanks Rezlo. With the original VE Upper oil pan only the 4 bolts on the left(from driver seat) line up, using the RWD pan allows the bottom 4 bolts also to be usable, Only the 3 of 4 bolts around the starter is still out of alignment, but this is a easy fix with a few pieces of metal.

Posted on: 2010/7/6 8:53

Edited by racetech on 2013/12/24 6:51:14

|

|

|

|

|

Re: racetech's 1200 SR20VE Project |

|

Home away from home

Joined:

2009/4/16 10:37

From Cape Town, South Africa

Group:

Registered Users

|

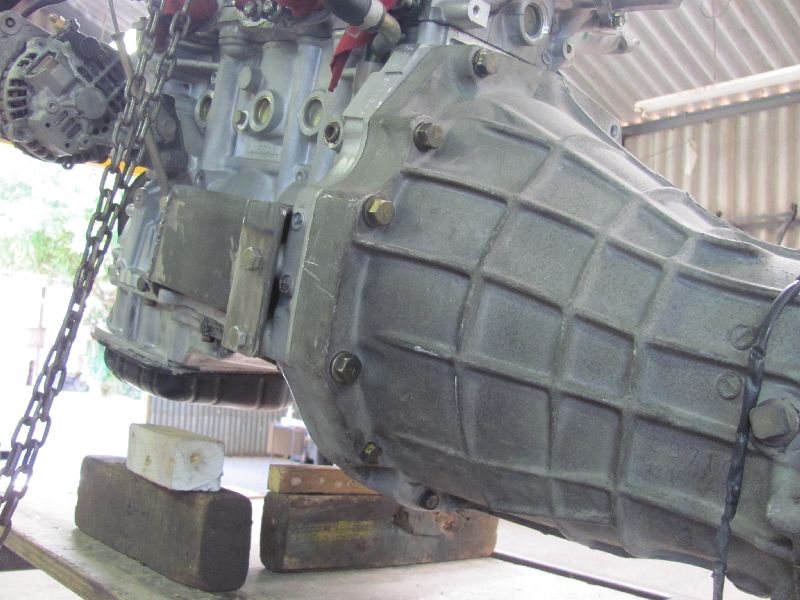

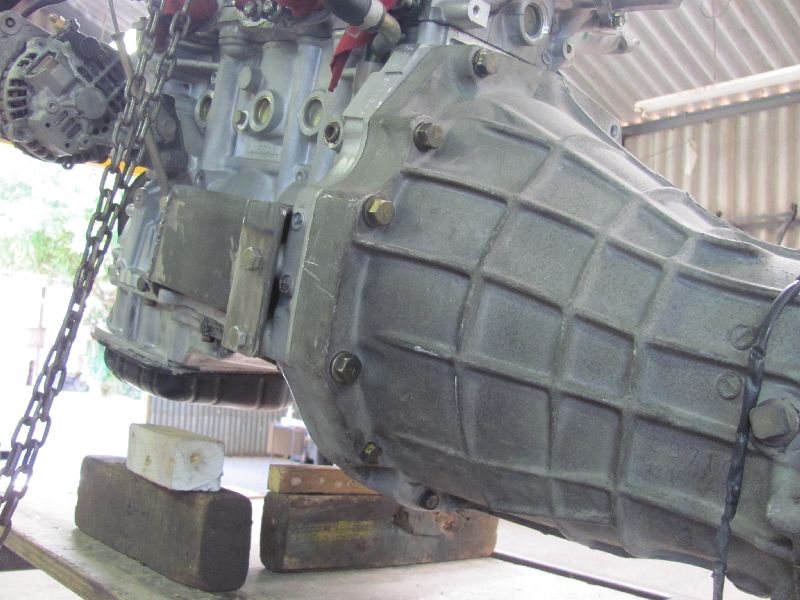

24 April 2010 – SR Power Mounted & Floors Removed          One of the biggest challenges right from the beginning of this motor and gearbox combination was the alignment of the bell housing bolts, if you take the standard motor and gearbox, only 4 bolts on the right hand side is in alignment, this meant I had to make a adapter plate, something I was not looking forward to. Rezlo ([img]http://www.rezlo.com"> www.rezlo.com</a>), well known SR guru in South Africa advised me to use the RWD upper oil pan from the S14 SR20DET motor. After sourcing one it quickly became apparent that this is the way to go as know 8 bolts was in alignment, 4 on the right and 4 at the bottom, luckily the 4 most important bolts on the bottom was covered.     While the sump and upper Oil pan was off, I noticed the condition of the motor on the inside, no sludge, clean oil with no debris, absolutely no sign of any white metal or other metal particles in the sump. The other interesting thing was the half counter-weighted crank, probably the reason why the VE motors has the tendency to rev very high, well higher that the building block motor the SR20DE. After some additional home work, it became quite apparent that the VE also boost lighter internals like the rods and pistons.   Cross member was removed and the old A12 mounting uprights was cut off. From sheet metal new uprights was designed and build. These were placed at a angle to facilitate the installation and removal of the motor. New engine mounts had to be designed as it was not included with the motor, so the serious mild steel sizes was pulled from the shelf and we got started on the mountings, we wanted to support as much as possible over the largest area, thus the strange looking mountings. Looking back this may have been a bit over the top as there is no weak points in the mountings itself that could aid in the case of a accident to absorb shock.     The old floors in the car was due for a replacement and the bigger S14 gearbox also meant that we would need to enlarge the transmission tunnel, due to this we decided to remove the floors and transmission tunnel and start from scratch as it would be easier than struggling with old pieces of sheet metal. We started with the floors, cutting away everything that had rust damage and bad dents followed by the transmission tunnel. After some careful measurements we started with the firewall and while we were at it also the old pedalbox mountings, as this was due for replacement by a forward swing bias adjustable unit. Motor and gearbox was again installed and the final part of the transmission tunnel removed.  Anybody else considering a conversion like this, here is a picture of the SR20DET RWD flywheel and the SR20VE Automatic flex plate. The ring gears is exactly the same. The reason way something like this was of interest to me was the fact that I'm planning on using the original FWD started mounting with the RWD gearbox. Main reason for this is that I can keep my block original and use the FWD starter that I got with the motor. Only problem with this is the fact that you need a expert to remove some material from the outside of the flywheel to get the FWD starter to fit over it, also a smaller pressure plate need to be used with the RWD flywheel.

Posted on: 2010/7/22 12:09

Edited by racetech on 2010/7/23 7:20:29

Edited by racetech on 2013/12/24 6:49:50

|

|

|

|

|

Re: racetech's 1200 SR20VE Project |

|

Just can't stay away

Joined:

2008/7/30 6:37

From Trinidad and Tobago, West Indies

Group:

Registered Users

|

awesome stuff, I am really interested in how you plan to do the IRS and coilovers in the rear and mount the BMW diff

keep this thread updates please!!

Posted on: 2010/7/22 14:38

|

|

|

|

|

Re: racetech's 1200 SR20VE Project |

|

Home away from home

Joined:

2009/4/16 10:37

From Cape Town, South Africa

Group:

Registered Users

|

bezman I'm busy getting this thread updated, it will just take some time as I'm quite busy with work and maintaining our racing vehicles.

This weekend we will start with the diff mountings, will keep the updates flowing.

Posted on: 2010/7/22 18:57

|

|

|

You can view topic.

You cannot start a new topic.

You cannot reply to posts.

You cannot edit your posts.

You cannot delete your posts.

You cannot add new polls.

You cannot vote in polls.

You cannot attach files to posts.

You cannot post without approval.

|

Transfer

Transfer