| Revision as of 03:42, 14 February 2012 ddgonzal (Talk | contribs) <- Previous diff |

Revision as of 04:32, 14 February 2012 ddgonzal (Talk | contribs) Next diff -> |

||

| Line 1: | Line 1: | ||

| Datsun 1200's A12 engine uses a roller chain-driven camshaft. The camshaft is located on the right side of the engine block, and drives the valves via pushrods and rocker arms. The camshaft also drives the [[Oil pump]] and distributor. Camshafts are physically different starting with 1974 model year engines, because the newer engines have the distributor in a different location. | Datsun 1200's A12 engine uses a roller chain-driven camshaft. The camshaft is located on the right side of the engine block, and drives the valves via pushrods and rocker arms. The camshaft also drives the [[Oil pump]] and distributor. Camshafts are physically different starting with 1974 model year engines, because the newer engines have the distributor in a different location. | ||

| - | Also see: | + | = Also See= |

| - | * [[Camshaft replacement]] | + | * [[Camshaft replacement]] |

| - | * [[Camshaft Comparison]] | + | * [[Camshaft Comparison]] |

| - | * [[Timing Chain]] | + | * [[Camshaft Timing]] |

| - | + | ||

| == Cam Interchange == | == Cam Interchange == | ||

| - | Datsun A10 & 1200 engines, with the distributor at the front, use a single drive gear to drive both the oil pump as well as the distributor. | + | Datsun 1200 engines, with the distributor at the front, use a single drive gear to drive both the oil pump as well as the distributor. Only Datsun 1970-1973 A12 engines and A10 engines use this arrangement. |

| - | + | ||

| - | From 1974 ALL Datsun A series engines used a second drive gear as the distributor was now re-located back where the earlier fuel pump once was. | + | |

| + | From 1974 all Datsun A-series engines (other than A10) used a second drive gear as the distributor was now re-located back where the earlier fuel pump once was. | ||

| Strict interchange | Strict interchange | ||

| Line 21: | Line 20: | ||

| * Early cam [one gear] = Can be used only in early engines, if you want to use a standard type distributor ignition system. | * Early cam [one gear] = Can be used only in early engines, if you want to use a standard type distributor ignition system. | ||

| You can use the later cam in the earlier block as long as you block off the fuel pump mounting & run a different pump [electric?], but if you wish to use the distributor in a later engine, then the earlier cam will not work as you get a fuel pump eccentric instead of a drive gear at that point. | You can use the later cam in the earlier block as long as you block off the fuel pump mounting & run a different pump [electric?], but if you wish to use the distributor in a later engine, then the earlier cam will not work as you get a fuel pump eccentric instead of a drive gear at that point. | ||

| - | |||

| == Valve Timing Specifications == | == Valve Timing Specifications == | ||

| Also see: [[A12GX Engine]] | Also see: [[A12GX Engine]] | ||

| - | * A12: 248° | + | * A12: 248°, .315" (8 mm) lift |

| - | * A12GX: 256° .331 lift | + | * A12GX: 256°, .331 (8.4mm) lift |

| - | + | ||

| Here are the specs used in the standard B110 camshaft (from 1973 USA factory manual): | Here are the specs used in the standard B110 camshaft (from 1973 USA factory manual): | ||

| Line 39: | Line 36: | ||

| NOTE: It is unclear at which valve lift specifications this is measured at. So be wary of comparing other camshaft specs. | NOTE: It is unclear at which valve lift specifications this is measured at. So be wary of comparing other camshaft specs. | ||

| - | + | B = before | |

| - | * Lift: ??? | + | A = after |

| - | + | TDC = Top Dead Center | |

| - | B = before | + | |

| - | + | ||

| - | A = after | + | |

| - | + | ||

| - | TDC = Top Dead Center | + | |

| == New Camshaft Break-in == | == New Camshaft Break-in == | ||

| - | * Discussion: | + | Discussion: |

| - | + | ||

| - | + | ||

| - | IMPORTANT | + | |

| + | IMPORTANT | ||

| * Always use new lifters with a new or rebuilt camshaft | * Always use new lifters with a new or rebuilt camshaft | ||

| * Coat the cam lobes with break-in lube | * Coat the cam lobes with break-in lube | ||

| * When you first start the motor, run it at 2000rpm for 20 minutes to break in the cam. Set the timing as best you can, fill the carbs with gasoline THEN start the motor and don't shut it down for minor leaks or problems until the 20 minutes are up. Otherwise the camshaft will soon wear out from improper break-in. | * When you first start the motor, run it at 2000rpm for 20 minutes to break in the cam. Set the timing as best you can, fill the carbs with gasoline THEN start the motor and don't shut it down for minor leaks or problems until the 20 minutes are up. Otherwise the camshaft will soon wear out from improper break-in. | ||

| - | |||

| == Installation == | == Installation == | ||

| Go to the public library and check out a [[Repair manual]]. You can either get a 1200-specific book or one of those that covers many kinds of cars -- they all have timing chain installation information. | Go to the public library and check out a [[Repair manual]]. You can either get a 1200-specific book or one of those that covers many kinds of cars -- they all have timing chain installation information. | ||

| - | |||

| === Timing === | === Timing === | ||

| Line 71: | Line 59: | ||

| [http://datsun1200.com/modules/myalbum/photo.php?lid=5767 http://datsun1200.com/modules/myalbum/photos/thumbs/5767.jpg] [http://datsun1200.com/modules/myalbum/photo.php?lid=16844 http://datsun1200.com/modules/myalbum/photos/thumbs/16844.jpg] | [http://datsun1200.com/modules/myalbum/photo.php?lid=5767 http://datsun1200.com/modules/myalbum/photos/thumbs/5767.jpg] [http://datsun1200.com/modules/myalbum/photo.php?lid=16844 http://datsun1200.com/modules/myalbum/photos/thumbs/16844.jpg] | ||

| - | |||

| # Make sure engine front pulley is on the mark (0 or Top) | # Make sure engine front pulley is on the mark (0 or Top) | ||

| Line 78: | Line 65: | ||

| # Check distributor to confirm TDC -- if the rotor is not pointing at spark lead #1, rotate the engine 1/2 turn to line up the mark again | # Check distributor to confirm TDC -- if the rotor is not pointing at spark lead #1, rotate the engine 1/2 turn to line up the mark again | ||

| # Install the pulleys and chain such that the cam dowl hole lines up with the key groove | # Install the pulleys and chain such that the cam dowl hole lines up with the key groove | ||

| - | |||

| NOTE: Only for first-time install will the "match marks" line up. Once the engine is rotated, or if double-checking previous work, the match marks *will not* line up. This doesn't indicate a problem as the match marks are only used when putting the chain on, just check that the centers line up. | NOTE: Only for first-time install will the "match marks" line up. Once the engine is rotated, or if double-checking previous work, the match marks *will not* line up. This doesn't indicate a problem as the match marks are only used when putting the chain on, just check that the centers line up. | ||

| - | |||

| '''Be very careful, even if off by one tooth the engine won't work exactly right.''' If it doesn't look perfect, re-do it. If you are careful, you can tell if it is a tooth off, or not. Use a level or a t-square or some other precision straightedge as an tool to make sure they line up -- exactly. | '''Be very careful, even if off by one tooth the engine won't work exactly right.''' If it doesn't look perfect, re-do it. If you are careful, you can tell if it is a tooth off, or not. Use a level or a t-square or some other precision straightedge as an tool to make sure they line up -- exactly. | ||

| - | |||

| For a competition camshaft, use the manufacturer's recommended procedure, usually something like this: | For a competition camshaft, use the manufacturer's recommended procedure, usually something like this: | ||

| - | + | <br>[http://datsun1200.com/modules/myalbum/photo.php?lid=3639 http://datsun1200.com/modules/myalbum/photos/thumbs/3639.jpg] | |

| - | [http://datsun1200.com/modules/myalbum/photo.php?lid=3639 http://datsun1200.com/modules/myalbum/photos/thumbs/3639.jpg] | + | |

| = Interchange = | = Interchange = | ||

| Line 111: | Line 94: | ||

| ** A15 Part Number 13001-H9800 CAMSHAFT A14 CAN | ** A15 Part Number 13001-H9800 CAMSHAFT A14 CAN | ||

| *: IN: 244, EX: 248 | *: IN: 244, EX: 248 | ||

| - | |||

| [http://datsun1200.com/modules/myalbum/photo.php?lid=18422 http://datsun1200.com/modules/myalbum/photos/thumbs/18422.jpg] | [http://datsun1200.com/modules/myalbum/photo.php?lid=18422 http://datsun1200.com/modules/myalbum/photos/thumbs/18422.jpg] | ||

| Line 120: | Line 102: | ||

| * Multi-hole. Using different holes | * Multi-hole. Using different holes | ||

| * Variable: Slotted holes allow a continuously variable range | * Variable: Slotted holes allow a continuously variable range | ||

| - | |||

| [http://datsun1200.com/modules/myalbum/photo.php?lid=682 http://datsun1200.com/modules/myalbum/photos/thumbs/682.jpg] Tomei [http://datsun1200.com/modules/myalbum/photo.php?lid=3639 http://datsun1200.com/modules/myalbum/photos/thumbs/3639.jpg] [http://datsun1200.com/modules/myalbum/photo.php?lid=3640 http://datsun1200.com/modules/myalbum/photos/thumbs/3640.jpg] | [http://datsun1200.com/modules/myalbum/photo.php?lid=682 http://datsun1200.com/modules/myalbum/photos/thumbs/682.jpg] Tomei [http://datsun1200.com/modules/myalbum/photo.php?lid=3639 http://datsun1200.com/modules/myalbum/photos/thumbs/3639.jpg] [http://datsun1200.com/modules/myalbum/photo.php?lid=3640 http://datsun1200.com/modules/myalbum/photos/thumbs/3640.jpg] | ||

| - | |||

| [http://datsun1200.com/modules/myalbum/photo.php?lid=7339 http://datsun1200.com/modules/myalbum/photos/thumbs/7339.jpg] Rollermaster | [http://datsun1200.com/modules/myalbum/photo.php?lid=7339 http://datsun1200.com/modules/myalbum/photos/thumbs/7339.jpg] Rollermaster | ||

| Line 135: | Line 115: | ||

| However, these can be fitted to any engine. The emission grind cam was used in A12A, A14 and A15 engine -- all with same cam part number. | However, these can be fitted to any engine. The emission grind cam was used in A12A, A14 and A15 engine -- all with same cam part number. | ||

| - | |||

| == 1967-1973 == | == 1967-1973 == | ||

| Line 146: | Line 125: | ||

| 13001-H0100 CAMSHAFT JPN B10 A10 | 13001-H0100 CAMSHAFT JPN B10 A10 | ||

| - | + | ADVERTISED DURATION | |

| - | ADVERTISED DURATION | + | |

| 248/248 duration | 248/248 duration | ||

| * 13001-H1000 A12 | * 13001-H1000 A12 | ||

| Line 185: | Line 163: | ||

| ** JPN B310 A14S, A15S | ** JPN B310 A14S, A15S | ||

| - | + | ADVERTISED DURATION | |

| - | ADVERTISED DURATION | + | |

| 248/248 duration (standard small bore) | 248/248 duration (standard small bore) | ||

| Line 207: | Line 184: | ||

| * 13001-H2300 GX CAMSHAFT (.331"/256 | * 13001-H2300 GX CAMSHAFT (.331"/256 | ||

| <!-- end editors note --> | <!-- end editors note --> | ||

| - | |||

| * 13001-H5700 A14E stock 256° 20/62/65/35/12/15 lift 8.4, clearance .35 | * 13001-H5700 A14E stock 256° 20/62/65/35/12/15 lift 8.4, clearance .35 | ||

| Line 237: | Line 213: | ||

| * the size of the engine, larger engine will need a slighter larger cam for same effective RPM range | * the size of the engine, larger engine will need a slighter larger cam for same effective RPM range | ||

| * the other equipment on the engine. For example, a stock Carburetor won't make more power over 6000 RPM | * the other equipment on the engine. For example, a stock Carburetor won't make more power over 6000 RPM | ||

| - | |||

| "Advertised Duration" means you should only compare these numbers with grinds from the same manufacturer. Other vendors may measure it differently. | "Advertised Duration" means you should only compare these numbers with grinds from the same manufacturer. Other vendors may measure it differently. | ||

| Line 270: | Line 245: | ||

| 08915-1361A WASHER-LOCK FIXING CAMSHAFT PLATE | 08915-1361A WASHER-LOCK FIXING CAMSHAFT PLATE | ||

| 08915-13610 WASHER-LOCK FIXING CAMSHAFT PLATE | 08915-13610 WASHER-LOCK FIXING CAMSHAFT PLATE | ||

| - | |||

| = Parts Suppliers = | = Parts Suppliers = | ||

| See: [[Parts Sources]] for current details and contact information for these vendors. | See: [[Parts Sources]] for current details and contact information for these vendors. | ||

| - | |||

| * Tomei: lifters, cams, sprockets, etc | * Tomei: lifters, cams, sprockets, etc | ||

Revision as of 04:32, 14 February 2012

Datsun 1200's A12 engine uses a roller chain-driven camshaft. The camshaft is located on the right side of the engine block, and drives the valves via pushrods and rocker arms. The camshaft also drives the Oil pump and distributor. Camshafts are physically different starting with 1974 model year engines, because the newer engines have the distributor in a different location.

Contents |

Also See

* Camshaft replacement * Camshaft Comparison * Camshaft Timing

Cam Interchange

Datsun 1200 engines, with the distributor at the front, use a single drive gear to drive both the oil pump as well as the distributor. Only Datsun 1970-1973 A12 engines and A10 engines use this arrangement.

From 1974 all Datsun A-series engines (other than A10) used a second drive gear as the distributor was now re-located back where the earlier fuel pump once was.

Strict interchange

- 1966-1973 cams interchange

- 1974-up cams interchange

Loose Interchange

- Late cam [two gears] = can be used in all engines, but conditions apply for early blocks

- Early cam [one gear] = Can be used only in early engines, if you want to use a standard type distributor ignition system.

You can use the later cam in the earlier block as long as you block off the fuel pump mounting & run a different pump [electric?], but if you wish to use the distributor in a later engine, then the earlier cam will not work as you get a fuel pump eccentric instead of a drive gear at that point.

Valve Timing Specifications

Also see: A12GX Engine

- A12: 248°, .315" (8 mm) lift

- A12GX: 256°, .331 (8.4mm) lift

Here are the specs used in the standard B110 camshaft (from 1973 USA factory manual):

- Exhaust open duration: 248 degrees

- Intake open duration: 248 degrees

- Intake opens at: 14 degrees BTDC

- Intake closes at: 54 degrees ABDC

- Exhaust opens at: 56 degrees BBDC

- Exhaust closes at: 12 degrees ATDC

NOTE: It is unclear at which valve lift specifications this is measured at. So be wary of comparing other camshaft specs.

B = before A = after TDC = Top Dead Center

New Camshaft Break-in

Discussion:

IMPORTANT

- Always use new lifters with a new or rebuilt camshaft

- Coat the cam lobes with break-in lube

- When you first start the motor, run it at 2000rpm for 20 minutes to break in the cam. Set the timing as best you can, fill the carbs with gasoline THEN start the motor and don't shut it down for minor leaks or problems until the 20 minutes are up. Otherwise the camshaft will soon wear out from improper break-in.

Installation

Go to the public library and check out a Repair manual. You can either get a 1200-specific book or one of those that covers many kinds of cars -- they all have timing chain installation information.

Timing

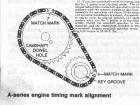

Rotate the crank until the key is in the position shown in the diagram.

The cam pulley is turned until the dowl hole lines up with the keyway. Then install the chain and double-check the alignment.

- Make sure engine front pulley is on the mark (0 or Top)

-

- When lined up, the engine will be at TDC or BDC

-

- Check distributor to confirm TDC -- if the rotor is not pointing at spark lead #1, rotate the engine 1/2 turn to line up the mark again

- Install the pulleys and chain such that the cam dowl hole lines up with the key groove

NOTE: Only for first-time install will the "match marks" line up. Once the engine is rotated, or if double-checking previous work, the match marks *will not* line up. This doesn't indicate a problem as the match marks are only used when putting the chain on, just check that the centers line up.

Be very careful, even if off by one tooth the engine won't work exactly right. If it doesn't look perfect, re-do it. If you are careful, you can tell if it is a tooth off, or not. Use a level or a t-square or some other precision straightedge as an tool to make sure they line up -- exactly.

For a competition camshaft, use the manufacturer's recommended procedure, usually something like this:

Interchange

For the A-series engine:

- All 1967-1973 camshafts interchange

- All 1974-2007 camshafts interchange

- In the A Engine Redesign for 1974 the location of fuel pump and alternator drives on the cam moved.

You can use the 1974-up camshaft in earlier engines. Earlier cams fit newer engines, but will not drive the distributor.

Engine displacment doesn't matter. In certain years, all A12 A14 and A15 engines were fitted with the *same* camshaft.

For example:

- 1982 B310 USA

- Part Number 13001-H9800 CAMSHAFT A12A, A14, A15 USA

- IN: 244, EX: 248

However, in other years and markets different specs were used. For example:

- 1982 B310 CANADA:

- A12A Part Number 13001-H5000 CAMSHAFT A12A CAN

- IN: 248, EX: 248

- A15 Part Number 13001-H9800 CAMSHAFT A14 CAN

- IN: 244, EX: 248

- A12A Part Number 13001-H5000 CAMSHAFT A12A CAN

Adjustable Cam Gear

Fitting an adjustable Camshaft gear lets you fine tune the timing. The cam vendor's recommendations are usually best, but retarding the cam a degree or two will generall shift the torque curve higher up in the RPM range. Advancing the cam will (usually) lower the power curve a few RPM. Adjustable gears come in a few basic kinds:

- Multi-key. Rollmaster had one with nine adjustible keys in the crank sprocket

- Multi-hole. Using different holes

- Variable: Slotted holes allow a continuously variable range

Cam Profiles

There are basically four factory grinds:

- small bore grind

- large bore grind

- performance grind, used in GX, Twin-carb, and EFI engines

- emission grind, used in 1981-1982 USA engines

However, these can be fitted to any engine. The emission grind cam was used in A12A, A14 and A15 engine -- all with same cam part number.

1967-1973

13001-H7000 ASSY-CAMSHAFT USA B110 A12 0772- 0 13001-H2300 13001-H2300 CAMSHAFT B110 JPN A12 GX 13001-H1000 CAMSHAFT B110 USA JPN A12 13001-18001 CAMSHAFT B10 JPN A10 0470- * replaces 13001-18000 & 13001-H0100 13001-18000 CAMSHAFT JPN B10 A10 13001-H0100 CAMSHAFT JPN B10 A10

ADVERTISED DURATION 248/248 duration * 13001-H1000 A12

256/256 duration .331 lift * 13001-H2300 A12 GX

1974-up

EMISSION PROFILE 13001-H9800 CAMSHAFT [Typical use: 1981-1982 USA B310 & N10] *: 244/248 duration ** USA B310 A14,A15 B310 0880- ** USA B310 A12A 0880- B310

PERFORMANCE STOCK PROFILE 13001-H5700 CAMSHAFT [Typical use: Performance engine] *: 248/256 duration .331 lift ** JPN B210 A12T, A14T ** JPN B310 A14E, A15E

SMALL BORE PROFILE * 13001-H5000 CAMSHAFT [Typical use: A12S] *: 248/248 duration ** JPN B120 A12S ** JPN B210 A12S ** JPN B310 A12S, A13S ** USA B310 A12A 0879-0780 ** CAN B310 A12A

LARGE BORE PROFILE * 13001-H6200 ASSY-CAMSHAFT [Typical use: A14/A15] *: 248/256 duration ** JPN B210 A14S ** USA B210 A13, A14 ** USA B210 F10 A14 ** USA B310 A14,A15 -0780 ** JPN B310 A14S, A15S

ADVERTISED DURATION

248/248 duration (standard small bore) * 13001-H5000

248/256 duration (standard large bore) * 13001-H6200

256/256 duration (performance engines) * 13001-H5700 .331 lift 244/248 duration (Late USA emission) * 13001-H9800

Nissan Competition Parts

CAMSHAFTS & RELATED COMPONENTS (A-SERIES)

PART NO. DESCRIPTION QTY REQ.

- 13001-H2300 GX CAMSHAFT (.331"/256

- 13001-H5700 A14E stock 256° 20/62/65/35/12/15 lift 8.4, clearance .35

- 13001-H5710 70° camshaft 280° 38/62/65/35/12/15 lift 9.4, clearance .25

- recommended for rallies

- limit RPM 7600, normal RPM 7200

- 13001-H5711 74° camshaft 296° 46/70/73/43/12/15 lift 9.4, clearance .25

- recommended for gymkhanas

- limit RPM 7800, normal RPM 7400

- 13001-H5712 80° camshaft 320° 58/82/85/55/12/15 lift 10.5, clearance .25

- recommended for racing

- limit RPM 8500, normal RPM 8000

- 13001-H5713 82° camshaft 328° 62/86/62/55/12/12 lift 10.5, clearance .25

Aftermarket Camshafts

Replacement camshafts don't have to come from Nissan. You can get them from most cam grinders.

Most cam grinders will make a camshaft for a Datsun 1200. Most cams are made on request you won't find it listed in a catalog. You supply a used cam, they do the rest.

For example, Camtech advertises these camshaft profiles for Datsun A engines:

- #618 RPM RANGE 2000-6000 239/231 (Advertised Duration)

- #639 RPM RANGE 2400-6400 254/254

- #621 RPM RANGE 2600-6800 260/264

- #609 RPM RANGE 3200-7200 277/284

- #608 RPM RANGE 4000-7800 290/295

- #604 RPM RANGE 4400-8200 301/310

Of course, the real RPM range will depend on:

- the size of the engine, larger engine will need a slighter larger cam for same effective RPM range

- the other equipment on the engine. For example, a stock Carburetor won't make more power over 6000 RPM

"Advertised Duration" means you should only compare these numbers with grinds from the same manufacturer. Other vendors may measure it differently.

Part Numbers

SET-BUSHING CAMSHAFT -- See Block * Not normally replaced as part of an overhaul

LIFTER-VALVE 13231-H1000 A12 13231-H1001 1970-1983 A12, A14, A15

B110 ASSY-CAMSHAFT 13001-H1000 USA, JDM 13001-H2300 GX 13001-H7000 USA 0772-

13010-18001 PLATE-camshaft second source 13010-18015 * 81-10616 BOLT (2) * 89-15136 WASHER-lock (2)

USA

B110 RAW LIST 13001-H7000 ASSY-CAMSHAFT 13001-H1000 CAMSHAFT 11023-78200 PLUG-TAPER 13032-18000 DOWEL-CAMSHAFT GEAR 13010-18001 PLATE-CAMSHAFT 08110-6161A BOLT-FIXING CAMSHAFT PLATE 01111-00022 BOLT-FIXING CAMSHAFT PLATE 08915-1361A WASHER-LOCK FIXING CAMSHAFT PLATE 08915-13610 WASHER-LOCK FIXING CAMSHAFT PLATE

Parts Suppliers

See: Parts Sources for current details and contact information for these vendors.

- Tomei: lifters, cams, sprockets, etc

- Iskenderian - legendary California hot rod Cam Grinder - mperdue has an Isky cam

- Crane: cams, springs, lifters

- Datrats

- APT

- Malvern Racing

- Yella Terra, roller pushrods

- CamTech - Australia

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)