Emission controls, first introduced in the US in 1964, have proven over time to be a good thing -- today's cars have very low emissions, but super-high power (in fact, they have more horsepower than pre-emissions cars). However, some of the early systems hurt engine performance, including some of those used by the Datsun 1200.

Overview

Nissan literature refers to three types of emission controls for the B110 model series:

- CRANK: Signifies all B110 with crankcase emission control device [PCV, etc]

- EXHAUST: Signifies all B110 with crankcase emission control and exhaust emission control device

- EVAPO: Signifies all B110 with crankcase emission control, exhaust emission control, and evaporative emission control device for CALIFORNIA in U.S.A.

- It appears that all USA models meet the California requirements as they all(?) have EVAPO parts

USA 1972 Owners manual (see pages 28-31 for details):

Are you familiar with the air pollution

control systems your Datsun is equipped with?

The four types of pollution targeted by 1971-1973 USA controls include:

- Gasoline vapors (EVAPO system), This means gasoline fumes escaping from the fuel tank, engine or any other part of the car

- Unburned Hydrocarbons (HC). Basically this means partially burned gasoline. Not only does it smell bad, it is toxic, cancer causing and contributes to smog. In a perfectly efficient engine, all HC would be converted to water (H2O) and Carbon Dioxide (CO2). This would result in the greatest fuel effiency. Since unburned gasoline means bad fuel economy this is a good performance goal, as well as an emission-control goal. Note that engines produce maximum horsepower with a rich air/fuel ratio for various reasons, but this is bad for pollution. Most cars run rich at full-throttle (even new cars) since it is generally not a strict part of emission test procedures.

- Carbon Monoxide (CO). As we all know from the movies, carbon monoxide can kill you. In low doses it can make you sick

- Oxides of Nitrogen (NOx) were restricted starting around 1974. They contribute to smog and acid rain. First EGR was used in the 1974 B-210, then later to meet stricter requirements, Catalytic Convertors were adapted starting with 1976 California B-210s

Nowadays Carbon Dioxide (CO2) emissions which -- as a greenhouse gas -- appears to contribute to the global warming effect. But it was not regulated in 1971-1973 automobiles.

For more information on automotive emission control, see wikipedia:Automobile emissions control.

Specifications

1973 Datsun 1200 USA emission specifications are as follows:

USA Federal (EPA): Test Procedure LA-4 CVS

- HC g/mile: 3.4

- HC g/mile: 3.2 (California ARB)

- CO g/mile: 39

- NOx g/mile: 3.0

- Evaporative g/test: 2.0

Carburetor Tuning

- Idle CO, manual transmission: 1.0-2.0% @ 800 RPM

- Idle CO, automatic transmission: 1.0-2.0% @ 650 RPM in "D"

Emission Testing

Some states have emission testing in urban areas. California is notable, but many other states also have a yearly or bi-yearly requirement.

The good news it that no state is currently requiring a Datsun 1200 to be tested. Datsun 1200s were made for model years 1971-1973 and so are past 25-year rules (e.g. Washington State) and 32-year (California) rules.

However, if you import a newer Datsun 1200 truck into your country, it will be subjected to the 15-year rule (Canada) or 25-year rule (USA). Vehicles newer than this will be required to meet emission control standards using a smog test.

Controls used by Datsun 1200s

Datsun 1200s in different markets came with different emission-control equipment. Some markets had minimal controls (those related to performance, like PCV) while USA models had the most controls to meet pioneering California rules.

Significantly, no 1970-1973 Datsun 1200 came with:

- EGR (first used on B210)

- Air Pump (Smog Pump) (first used on B210)

- Catalytic Converter (these first started with 1976 California models)

- high-temperature engine Thermostat

However later model Datsun 1200 trucks used these:

- EGR starting October 1989

Australia Models

- PCV system

- EVAPO with Carbon Canister (1980's utes)

- Air Cleaner with Compensator valve (1980's utes)

USA Models

Datsun 1200s came with:

- PCV system (fume control)

- EVAPO Evaporative System (fume control)

- ATC Temperature controlled air cleaner

- Revised Spark timing (engine ignition timing)

- Carburetor modifications

- Idle-return spring on carburetor. This is both an emission-control feature and a safety feature

- Revised carb jetting

- (1972-1973) Throttle Opener

- (1972-1973) Automatic Choke electrically operated

- (1973) Anti-diesel valve

- (1973) Higher Idle speeds

- (1973) Idle ajustment screw limiter cap

- Dash pot (automatic transmission models)

Details

PCV System

Positive Crankcase Ventilation (PCV) was the very first of the emission controls. This is a good system, and can actually help power and fuel economy.

See main article: PCV

EVAPO System (Fume Control)

All USA models, and later Japan and Australia 1200 pickups were required to control the amount of gasoline vapor that escapes from a vehicle into the atmosphere.

- The Datsun 1200 used an early system that consisted of a sealed gas tank, and hoses to route the fumes from carburetor, rocker cover and air cleaner to appropriate places. Be sure to use the original 1200 gas cap, which has no pressure vent (only an air inlet (vacuum relief) valve, which is normally closed).

- The later system uses a Carbon Canister

For details on how this works in the Datsun 1200, see Fume Control.

Ported Vacuum Advance

Ported vacuum for the distributor is provided by a carburetor fitting tapped just above the throttle plate. This gives zero vacuum at idle, but full vacuum at just above idle. This is not technically an emission-control method, and was used prior to emission control. However it does help reduce emissions. It is an OK system and there is no need to remove it. In fact, hooking up the distributor to the intake manifold directly will cause problems with setting the correct initial timing, as the standard specifications are for ported vacuum.

See: Vacuum advance

Revised Spark Timing

For reduction in unburned HC, generally the spark timing is reduced from optimal-power settings. This results in a more complete combustion under certain part-throttle conditions.

Because this reduces power, engine timing is dynamically controlled by various means, including:

- Revised mechanical advance. The curve comes on late, with reduced total advance

- Revised vacuum advance. The curve comes on late, with reduced total advance

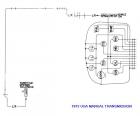

- Transmission Controlled Vacuum Advance System (TCVAS) A vacuum advance cutoff disables advance except in Top Gear

TCVAS

Starting with 1972 USA models, Transmission Controlled Vacuum Advance System (TCVAS) disables advance except in Top Gear. Since this "retarded" spark timing reduces performance, to prevent cold-engine driving problems this system is bypassed in cold temperatures. This means vacuum advance works normally at cold cabin temperatures.

See main article: TCVAS

Throttle Opener

USA

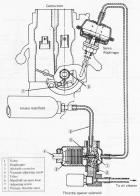

1972-1973 USA models use the Throttle Opener mounted on the carburetor to prevent the throttle from closing completely while the car is moving. This results in a drastic reduction of unburned HC. Carburetors are not efficient at high vacuum (closed throttle) high-speed conditions. So the Throttle Opener prevents this from occuring.

The Opener is operated by engine vacuum. When vacuum is supplied to the carb-mounted diaphragm, the 'phragm pulls a secondary throttle linkage which prevents the throttle shaft from returning all the way to idle.

To keep a smooth feel of the accelerator, the Opener only works at speeds above 10mph. This is accommplished by a vacuum switch mounted on the front of the intake manifold just in front of the carburetor.

The vacuum switch is operated electrically by the Amplifier Speed Switch, and electrical switch in the speedometer. Thus there is a hose from the intake manifold to the switch and from there to the the Opener diaphragm on the carburetor.

When the speed goes below 10mph, the vacuum switch opens (12V "on"), and vacuum in the diaphragm slowly bleeds off through a small jet and needle valve in the vacuum switch. Thus the throttle gradually closes all the way. It is a smooth transition you won't even notice. The vacuum bleeds off by letting clean air enter from the air cleaner. Thus there is a small hose from the switch to the air cleaner.

In automatic-transmission cars, the vacuum switch is "off" in Neutral and Park (12V supplied to solenoid).

At idle, there should be 12 volts supplied to the vacuum switch/solenoid unit. Also it should be supplied with engine OFF, Ignition Switch ON.

CAUTIONS

The Opener used on the Datsun 1200 is fairly unobtrusive. It keeps the throttle slightly open during deceleration. Some newer cars made in the late 70s used fairly radical Openers that kept the engine at relatively high rpms and made for odd, highly noticeable throttle experience. So if you are using a newer carburetor, keep this behavior in mind.

Troubleshoot: Note that in the factory service manual, there are extensive procedures, diagrams, specifications and drawings. You should borrow, buy, or check it out from the Library.

Takes a long time to return to idle

- There is a screw adjustment on the solenoid. Adjust it to Nissan factory manual specifications. This is rarely a problem unless someone changed this setting. Normally it is set at the factory, and never touched again.

Idles noticeably high While Decelerating

- Adjust the Throttle Opener linkage on the carburetor per carburetor specifications.

Idles too high at Idle

The Throttle Opener is de-activated only when the electrical connections are working correctly. If the wires becomes disconnected, it is "on" which results in an idle-speed problem.

- If you have 0V to the solenoid at idle, one of the following is indicated:

- Auto trans Inhibitor Switch stuck "off"

- bad wiring, or wiring disconnected under-hood, or under dash

To test for proper electrical operation, connect a voltmeter to the switch with wires into the cabin. Use a voltmeter to read the voltage while driving. It should switch from 12V to 0V at approximately 10mph. you have 12V to the solenoid at speeds above 10mph, one of the following is indicated:

- electrical switch on speedometer is stuck "on"

- Part Number 25035-H7000 for 1973 USA model from 0772 name: Speed Switch Amplifier Assembly

- newer Utes also use a similar/same part: 68600-AN8500 (?)

- For 1973 models, the outgoing wire is LR (Blue with red stripe)

- wrong speedometer fitted (one with no switch)

Vacuum Leaks

Lastly, since the Opener is operated by engine vacuum its parts are a potential source of "vacuum leak". See Vacuum_Leaks. If you suspect a leak, simply plug the port on the intake manifold:

- If the engine idles better, it indicates a bad hose, a bad vacuum switch or lack of 12V to the solenoid.

- Check hoses for cracks (especially at the ends), burns or other visible problems

- There is a one-way valve in the vacuum switch to prevent air from going into the intake manifold port. You can blow on the diagphragm side. If air comes out the Intake port of the switch, it is defective. Replace it or plug the intake port to disable the entire Opener system.

- If the engine runs better at speed, it indicates:

- a leak in the carb-mounted Diaphragm

- (less likely) a leak in the Opener solenoid

B120 Amplifier Speed Switch

Amplifier Speed Switch for B120 ute Throttle Opener Assembly (see Emission Controls). It's only fitted to the Manual Transmission models.

The speed detecting switch is part of the speedometer assembly and is installed in the speedometer. The amplifier prevents damage to the speed detecting switch which actuate the throttle opener only when the car speed is above 10km/h. Pub No. SM6E-EMC0A0, Page EC-11

Also see: Wiring

If your ute is missing the Switch, no worries. It drives OK without it, just slightly more emissions above certain speeds when decelerating.

Revised carb jetting

To reduce the amount of Carbon Monoxide (CO) and Unburned Hydrocarbons (gasoline), carb jetting is carefully controlled to burn the gasoline efficiently. The advanced original-equipment Hitachi DCH/DCG carburetors were fairly good in this regard. For the US market they were modified slightly lean in part-throttle use to reduce emissions. In general, Datsun 1200 carbs are richer than newer Datsun carburetors. Full-throttle operation, not being tested by US law, remained rich.

However, after the Datsun 1200 years, the Hitachi was modified with more and more controls, increasing complexity and reliability.

Higher Idle Speed

Some models use a higher idle speed, higher than 600rpm. This allows more air through the carb at idle, and so the carburetor is better able to mix the air/fuel ratio. However it does cause two problems:

- Engine "run on", where the engine "diesels" (won't stop running) after the ignition is turned off. 1973 models compensate for this by using the anti-diesel valve (fuel cut-off valve).

- Increase noise. The A12 engine is much quieter at 600rpm than at 750 rpm.

1973 US models feature an "idle-limiter cap" on the carb's idle speed screw so that users won't accidently change the idle too much. This is primarily to control CO emissions. As the years go by and the carb wears and air leaks past the throttle shafts, it may be necessary to remove the cap to adjust the carburetor to a "good enough" setting.

Temperature Controlled Air Cleaner

Nissan "Automatic Temperature-Control Air Cleaner" (A.T.C. Air Cleaner)

Temperature Controlled Air Cleaner has two effects:

- Prevent carburetor "icing" in cold weather (near freezing to below freezing). Markets otherwise without emission control requirements used a simple "summer/winter" manual lever on the air cleaner air intake snout

- Keep the carburetor air at a constant temperature. This way the carburetor can be more effective over a wide range of ambient (outside) air temperatures. This is sometimes called a "hot air" system. Nissan calls it "Automatic Temperature-Control Air Cleaner" (A.T.C. Air Cleaner)

Even non-emission models used heated air. Here is a JDM air cleaner with manual temperature switch:

The Automatic hot air system not only reduces pollution, but by ensuring the carburetor is fed a constant-temperature air it aids fuel economy as well. The carb can be tuned for slightly-lean cruising operation without be affected by cold temperatures. Only disable this system if you want maximum performance and are willing to re-jet the carburetor to match particular temperatures. Racers will sometimes re-jet for different days and track conditions.

The ATC system consists of:

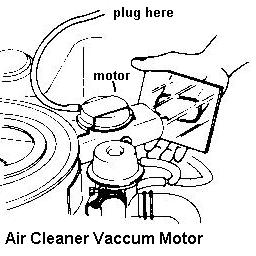

- special air cleaner. The cleaner gas normal cold-air intake into the snout, but with a hot air intake below. A vacuum-controlled diaphragm motor controls a valve inside the snout and makes this system easy to recognize (look for a large 2" round diphragm on top of the snout)

- A special abestos or aluminum clad "hot air" hose (about 1-1/4 inches in diameter) going from the exhaust manifold to the bottom of the snout. Non-emission cleaners also have this for the summer position

- A special temperature regulating valve in the air cleaner proper. This modulates the flow of vacuum to the Diaphragm.

- Two hoses:

- One connecting the diagphragm to the ATC valve

- The other from ATC valve directly down to the intake manifold vacuum port

Part Numbers

USA B110

- 16510-H3900 ASSY-MOTOR,VACUUM 0671- $56.07 USD

- 16580-01B01 ASSY-SENSOR,TEMPERATURE

- originally 16580-H3900 0671- $60.78 USD [1986-1987]

Automatic Choke

1972-up USA models used an automatic choke to better control air/fuel mixtures when the engine was warming up.

For details on the choke operation, see Carburetor Adjustment.

EGR

EGR (Exhaust Gas Recirculation) was first used starting with 1974 B-210 (North American B210) models. It recirculates a small portion of the exhaust back into the combustion chamber. Although this dilutes the the air/fuel mixture (reducing performance), the inert properties of the spent gas reduces burning temperatures resulting in drastic reductions of Oxides of Nitrogen (NOx).

See main article: EGR

Catalytic Convertor

Catalytic Convertor were first fitted to 1976 Calfornia-models B-210s then to non-California B310s generally around 1980 or so. The converter fits into the exhaust pipe system, and converts unburned hydrocarbons (unburned fuel) into less-harmful substances--namely water and oxygen. Early convertors were a restriction in the exhaust system, but newer designs are high-flow. New designs are not too bad of a system, although some use the Air Pump to supply extra oxygen to the convertor. You can simply replace the convertor with a straight section of exhaust pipe.

Air Injection System

A.I.S. is Air Injection System. This pumps air into the exhaust system to further burn the exhaust -- which reduces HC and CO. The additional air is injected into a passage drilled lengthwise in the head from front to back, and which has cross-passages drilled to each exhaust port. So it gets the exhaust into "recombustion" as it leaves the cylinder.

Head with 11mm air passage (to left of large thermostat hole):

This alone does not hurt performance. However early versions used an air pump which takes some power to run. Later passive versions used no air pump so had minimal effects on performance.

Maintenance

- The Air pump air cleaner requires periodic replacement.

- The air pump uses carbon shoes, so eventually wears out. The pump may seize at this point.

Air Injection System with Air Pump

The air pump system -- a.k.a. "smog pump" -- was first fitted to some 1960s Datsuns.

No Datsun 1200 was fitted with an air pump. The first B-series models to have an Air Pump was the North American B210 series for 1975.

See main article: Smog Pump

Exhaust Air Induction

Japan B310, similar to A.I.S. See the next section.

Air Induction System without Air Pump

1977 USA GFU B210s and 1978 Canada B210s use a simplified A.I.S. (Air Induction System). No air pump is used, but instead air flows via tuned port pulsation.

Components:

- Carb Air Cleaner subfilter and induction valve

- Check valve before going into head (Canada only). Canada injects air into cylinder head passage. Federal models inject into exhaust manifold

- 1980 models use a C.A.C. valve which controls flow to prevent overheating of catalytic convertor. One hose tees into the pump output, the other hose dumps to the air (apparently not connected to anything). This valve has a single vacuum hose to control it

- Anti-backfire valve between Carburetor air cleaner and intake port (port on intake manifold). This valve has a single vacuum hose to control it

Idle Compensator

Late model (circa 1983) Australian utes, and USA 1200s, came with an air cleaner with a idle compensator.

Which controls can be eliminated?

For a race car, any you want may be removed -- though some are good for the engine.

For a road car, it depends on the local laws. Here are some thoughts on the technical aspects:

- Positive Crankcase Ventilation (PCV): This is a good system, and can actually helps power and fuel economy. If you remove it, you should design an alternative system to keep oil out of the air, and oil fumes from causing sludge inside the engine. It is recommended to keep this for all street cars.

- Ported vacuum for vacuum advance is the carburetor fitting tapped just above the throttle plate. This gives zero vacuum at idle, but full vacuum at just above idle. This is a good system, and removing it (disconnecting Vacuum Advance) will result in poor part-throttle acceleration and fuel economy. Connecting the distributor directly to the intake manifold can cause timing setting problems, as the standard specifications are for ported vacuum.

- Fuel Tank vapor recovery: This is a good thing, as why let gas fumes get into the air? They are easily controlled by venting the tank and the carburetor float bowl to a charcoal canister. See your Datsun repair manual for an explanation of the various schemes used over the years. Also see Fume Control.

- EGR (Exhaust Gas Recirculation) hurts performance, and should be blocked for a race car. The easiest way is simply to remove the vacuum hose and block it with a plug. For a more streamlined look, remove the EGR valve and replace it with a block plate, and the hoses that control it. No other change is need, however if your engine starts to "ping" (pink) then either fit a 160-degree thermostat or carefully tune the engine to compensate.

- Air Pump (aka Smog Pump). This takes power to run, so for an off-road car should be removed. Remove the pump, block the exhaust manifold opening for it, and block the air hose fittings that are on the air cleaner.

- Catalytic Convertor can be removed for off-road vehicles with no loss of performance. Simply replace the convertor with a straight section of exhaust pipe.

- Throttle Opener is a fairly unobtrusive system on Datsun 1200s. It is recommended to keep it intact on a street car. For racing, where a 'snap' of closing throttle is desired, or where the Opener is defective, simply plug the port on the intake manifold thereby disabling the entire Throttle Opener system. No loss of performance will result, though invisible pollution will increase.

- TCVAS. For full performance in off-road vehicles:

- connect a hose directly from the Carburetor's vacuum advance port to the distributor

- Plug the hose going to from the Flow Guide Valve hose to the the Vaccuum cut off switch

- Optional: Remove Vacuum Cutting Valve Solenoid. Tape over wires

- A.T.C. Air Cleaner: Only disable this system if you want maximum performance and are willing to re-jet the carburetor to match particular temperatures. Racers will want to do this, although for best performance they should be willing to re-jet for different days and track conditions. The ATC increases fuel economy without having to re-jet for different ambient air temperatures, like summer vs. winter, night vs. day, etc. In constant-temperature climates, ATC is not as helpful.

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)