| Revision as of 09:58, 21 November 2012 ddgonzal (Talk | contribs) (->Part Numbers) <- Previous diff |

Revision as of 05:19, 18 February 2013 ddgonzal (Talk | contribs) (->Overview) Next diff -> |

||

| Line 24: | Line 24: | ||

| [http://datsun1200.com/modules/myalbum/photo.php?lid=11151 http://datsun1200.com/uploads/thumbs/11151.jpg] | [http://datsun1200.com/modules/myalbum/photo.php?lid=11151 http://datsun1200.com/uploads/thumbs/11151.jpg] | ||

| + | |||

| + | = Inspection = | ||

| + | If the starter made ocassional grinding sounds, chances are the flywheel ring gear needs replacing (or just replace the whole flywheel, which is often less expensive). | ||

| + | |||

| + | Yes, you should turn the flywheel if it is not in good shape!!! Better to not re-grind the flywheel if it doesn't need it. | ||

| + | |||

| + | It is not indicated to resurface the flywheel UNLESS cracks appear, or it is not flat (worn unevenly), or the surface is burnt (heavy glazing). Guys will tell you "it is cheap insurance" to machine the flywheel regardless, but that's not what the Datsun factory service manual says. | ||

| + | |||

| + | If it is warped, have it resurfaced. It is it burnt, chattered, or is grooved, resurfacing is called for. But it if still worked great, is flat, and not burnt, don't bother. The Nissan factory service manual does not recommend a resurface unless needed. Every time my Datsun flywheel did not look great, I should have resurfaced it. And everytime it looked great and I didn't resurface it, all was fine. | ||

| = Lightening = | = Lightening = | ||

Revision as of 05:19, 18 February 2013

Datsun 1200 uses a traditional type of flywheel at the back of the engine. The face matches the Clutch while a ring gear is attached to the perimeter for the Starting Motor to turn the engine. It uses a 271mm (10.7 inch) flywheel with a 105-tooth ring gear.

Contents |

Overview

All flywheels for A-series engines interchange -- for rear-wheel drive vehicles. The A12 flywheel weighs 2.2 lbs (1 kg) less is the main difference. The A12 flywheel is also thinner.

A10 8.0 kg (17.6 pounds) A12 12310-H1000: 9.5 kg (20.8 pounds) A12 12310-H2310: 6.4 kg (14.1 pounds) GX, also sold as 'Race Option' A14 12310-H7200: 10.7 kg (22.3 lbs)

A14/A15 flywheel is thicker than the A10/A12 flywheel. When fitting the thinner flywheel to A14, remove the Engine Plate to compensate.

A10: 25 mm thick? (does not fit A12 due to different gear angle) A12: 28 mm thick (fits A10) A14: 30 mm thick

In 1974 flywheel bolts changed from British Threads to Metric threads. So the bolts are not interchangeable from early to late. See Crankshaft for details.

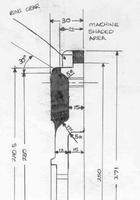

A12 Flywheel Measurements:

thickness: 28mm ring gear + backing: 20mm back rim to flywheel face depth: 5mm clutch face to inner face depth: 17mm

Inspection

If the starter made ocassional grinding sounds, chances are the flywheel ring gear needs replacing (or just replace the whole flywheel, which is often less expensive).

Yes, you should turn the flywheel if it is not in good shape!!! Better to not re-grind the flywheel if it doesn't need it.

It is not indicated to resurface the flywheel UNLESS cracks appear, or it is not flat (worn unevenly), or the surface is burnt (heavy glazing). Guys will tell you "it is cheap insurance" to machine the flywheel regardless, but that's not what the Datsun factory service manual says.

If it is warped, have it resurfaced. It is it burnt, chattered, or is grooved, resurfacing is called for. But it if still worked great, is flat, and not burnt, don't bother. The Nissan factory service manual does not recommend a resurface unless needed. Every time my Datsun flywheel did not look great, I should have resurfaced it. And everytime it looked great and I didn't resurface it, all was fine.

Lightening

For race cars, a light flywheel allows the engine to rev faster according to this principle:

The more weight, the more time it takes to accelerate

Now a street car wants a heavier flywheel, so that it will:

- smooth out the combustion pulses

- smooth out the drivetrain

These are the factory specs for flywheel weight reduction:

Finished wheight is about 6.5 kgs --a total of 2 kgs removal

Reference: Datsun B110 Competition Tune-Up Manual, Nissan Motor Co. Ltd., Tokyo Japan 1974

Bolts

Nissan flywheel bolts are very strong. Just clean the threads and use a torque wrench to install. ARP does not make A-series flywheel bolts, but in any case the stock bolts are strong.

If using the A-series over 7500 RPM, run new factory bolts and Loctite them.

If using high RPM and an unbalanced custom internals, someone suggested this: look at getting the crank flange dowelled. The flywheel is actually clamped on the head of the bolt not on the shank of the bolt (there is side-to-side play), so three dowels 120° apart should do the job. The end of the crank is soft unlike the journals and easy to drill.

Also see: Harmonic Balancer.

Part Numbers

- 12310-18001 ASS'Y-FLYWHEEL B10

- 12310-18002 ASS'Y-FLYWHEEL B10 (from E/# A10-87871)

- 12310-H1000 FLYWHEEL ASS'Y A12, A12S, A12A, A13S

- 12310-H6200 ASSY-FLYWHEEL A13

- 12310-H7200 FLYWHEEL ASS'Y A14 -7909

- 12310-H7201 FLYWHEEL ASS'Y A14 7910-8010

- 12310-H8900 FLYWHEEL ASS'Y V A14S, A15 8011-

- 12310-H8910 FLYWHEEL ASS'Y A14S, A15 8011-

- 12315-18001 BOLT-flywheel & drive plate (from E/# 87871) (6) B10

- 12314-18002 WASHER-flywheel

- replaced 12315-18000 BOLT-flywheel & drive plate (6) B10

- 12314-18001 WASHER-flywheel

- 12315-H1001 BOLT-flywheel (6, 3/8") B110 -1973

- 12315-H6200 BOLT-FLYWHEEL (6, 10mm) 1974-

- 12313-10600 DOWEL (3) all A-series A10-A15

- 12312-18000 GEAR-ring, flywheel A10/A12/A14

- 12312-18010 GEAR-ring, flywheel A14S 8110-

- BUSHING-pilot: see Pilot Bushing

The flywheel "Assembly" includes these parts: * 12312 GEAR-ring, flywheel * 12313 DOWEL-flywheel

- ATP ZA543 Flywheel Ring Gear $22.79

- http://www.rockauto.com/catalog/x,carcode,1208483,parttype,5360

- Outer Diameter=10.655"

- Inner Diameter 9.451"

- Pitch=10/12 Width=.400"

- Teeth=105

- Chamfer=FRONT #1231218000

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)