This gets discussed a lot and generally the two options it comes down to are this:

If you have the money, and can find one in good condition - the toyota t50 gearboxes are an option. Toyota boxes have a removeable bellhousing, and a local (Australian - so local to me at least!) company makes a conversion kit, which is mostly a new bellhousing to bolt on thee, and then a special clutch plate with toyota splines but a diameter to suit the a series. They also (*iirc) come with a gearbox yoke to suit a datsun tailshaft.

You'd still have to make stuff like a rear crossmember to support the new gearbox, amd of course you need to find a t series box in good condition (they are getting rarer here, not sure about other places)

The other option is the datsun 71 series boxes. They are strong enough for sure, but they don't have removable bellhousings, so you need to do a lot more work to fit them. basically you need to mount them on a steel pipe/bar (one that you make yourself) that fits tight into the crank/main tunnel of the engine block with the crank removed - that mounts the front gearbox 'snout' of the box at its other end - that lines up the engine and gearbox centrelines perfectly. then custom weld on a new front section to the bellhousing (you can cut one off a 56 or 60 series box and cut the 71 series bellhoousing and weld them together, or make custom new flat pieces and weld to the 71 box accordingly. You'd have to weld in the starter motor section.too.

Clutch wise - in this case you can actually get clutch plates for later model gearboxes that fit the diameter of the a-series (there's 3 different clutch plate diameters for L series engines, and one of them fits) but I'd suggest trying the 'middle' size. This would require you get the a15 flywheel drilled and tapped (and new dowels, and the surfaces machined to match) to suit the larger pressure plate but this middle size will fit on an a series flywheel, and the bigger diameter gives it more 'leverage' so for the same pressure it'll grip better). You have to heat up the bellhousings before welding or they will crack for sure when on the car.

What else - you need to take the input shaft out of the 71 series, and machine down the spigot (the finger at the front of the input shaft). It is so big on the 71 series boxes, that it won't fit inside the crank tail, even with a custom thin bush, so you need to grind it down to the a series box sizes (and you'll have to 'grind' it not machine it - what I mean is it is usually to hard to 'cut' on a lathe and you'll need to use a stone of some sort. It sounds very 'caveman' but I've actually done something like this by solid mounting a small 5 inch disc grinder on a lathe and turning shafts down that a cutting tip couldn't work on because the material was too hard (in this case it was a diff cross pin that I was adapting, and it had a similar surface hardness - I won't bore everyone with the details)

http://datsun1200.com/modules/myalbum/photo.php?lid=22569http://datsun1200.com/modules/myalbum/photo.php?lid=22568http://datsun1200.com/modules/myalbum/photo.php?lid=22570http://datsun1200.com/modules/myalbum/photo.php?lid=22571These are links to pics of the 'middle' sized L series motor clutch plate and pressure plate sitting on top of an a15 flywheel. It shows that the pressure plate will 'just' fit, and so you could re-drill, tap, and dowel the a15 flywheel to take this plate. The plate in the pics is not a standard one, it was behind the motor of an L16 powered rally car that was sold on this forum (long story short I ended up with some of the parts from it) so it's a non standard clutch plate, but it still shows the diamter.

apart from dowels and tapped threads, you also have to machine the flat parts of the flywheel to match up with the l series clutch plate. the a series has a slightly thicker raised sectionfor the clutch disc, you'd have to have it machined so that it had a full flat section in the new clutch plate area which is further outward.

OK, so that's the two main options used here. The strongest of the two would be (in my opinion) the 71b series (or a 71c i even stronger, but they tend to be a bit more expensive than 71b boxes) by a considerable margin. It is a lot more work, but sometimes that sort of work is no problem for a lot of people, and actually less trouble than trying to source a good toyota t50 box, and the cost of the conversion kit.

It is quite possible that where you are, different cars are more common, and a gearbox out of something else - I don't know maybe something like late 80s/early 90s volvo manual geaboxes are very cheap and there are plenty of spares - is what you could use.

There's at least one guy on this forum that is from Finland that has a turbo a series (and is rear wheel drive) - and another with a front wheel drive one also turbo. Have a look with the search function, you might find posts by them. I'll bet they could give better advice based on what boxes are practical to source in your region that will do the job.

Transfer

Transfer

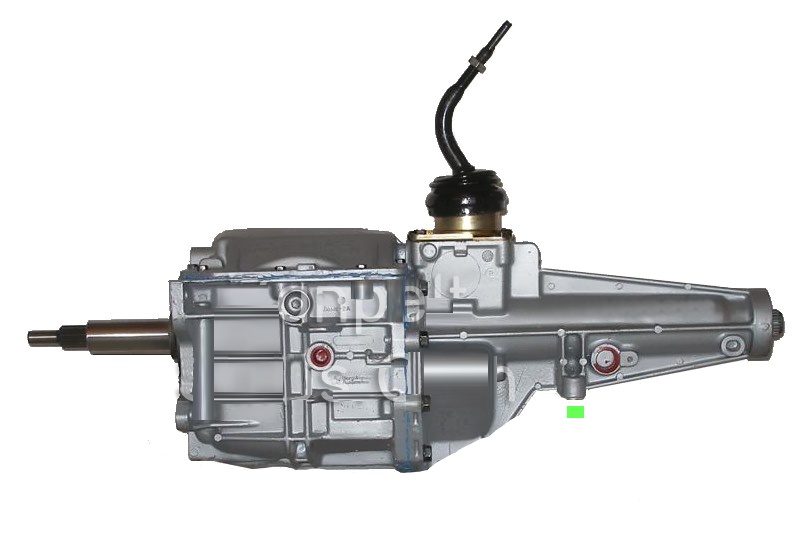

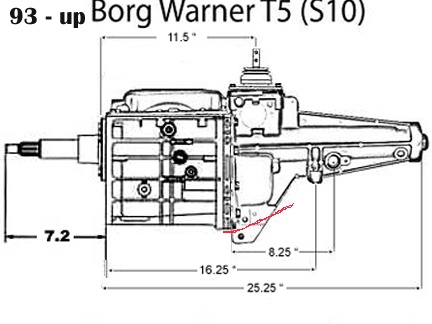

t5trans-leftside.jpg (61.97 KB)

t5trans-leftside.jpg (61.97 KB)