Forced Induction comes in two forms: Supercharging and Turbo-supercharging. Both work well in a Datsun 1200!

Contents |

Overview

One thing to remember is that a method that works well isn't the only good way.

POST Dodgeman: Forced induction. This is a subject that was vigorously & robustly debated in an extensive thread not so long ago, so have a play with the search function & you will likely find it.Myself, & a few others prefered the ability of the positive displacement blower to deliver high levels of torque, almost instantly, at very low engine speeds, while a large number of others prefered the advantages that a turbo offers at higher engine speeds. The turbo debate was further broken down into blow through versus suck through.

See if you can find this thread & have a read through it all. With some luck ou will gain an insight of the advantaged & disadvantages offered by each system.

A15: what to do turbo or supercharge?

- Should I swap the A15 1.5-liter for an L20B 2-liter? Or just turbo the A15?

- What will it cost?

- Will it be as fast as a common V8 ute?

The big discussion: regarding Turbocharging A12. Caution: difficult reading in that discussion.

Also see discussion: s/charged a14 (10 pages)

- Yes, an engine swap is easier & less expensive than forced induction. A $600 engine swap can be done in a weekend

- Forced induction can be done for about $1200 if you can do all the work yourself (including buying a used compressor and creating/fabricating the kit)

- Yes, forced induction on an A15 can be just as fast as a common V8 sedan, the 2-liter engine swap will not be

Supercharging vs. Turbocharging -- what's better?

A supercharger does not suffer from lag like a turbo does. The power increase is immediate because a supercharger is driven from the crankshaft of the engine. The turbo is better for maximum HP, the blower is better maximum torque. F1 engines used turbos instead of blowers (turbos were allowed in certain years, banned in other years).

See main article: Turbo

Generally speaking a centrifugal compressor requires revving the engine up. as the engine revs higher, turbocharging makes more and more power. So does centrifugal supercharging (Paxton, Vortech, PowerDyne, Procharger, etc.).

By contrast, a positive-displacement compressor makes power all through the RPM range and so makes the engine feel like a larger displacement engine. This includes roots-type blowers and screw-chargers. The blower requires HP to run, so the engine must be built stronger than a turbo motor of equal HP.

- Turbo: Less expensive, more HP. More complicated. Welding skills required

- Blower: More responsive. Easier to install. Fabricating skills important if a kit is not available

- twin-charged: blower for low RPMs, turbo for the rest. See A12RTT

Because there are no bolt-on kits available for Datsun 1200 (as of 2014), neither one is 'better'. Either pay a shop $$$ to convert your engine, or use your skills and time to do the same on the cheap. Either way the result is a lot more HP for less money than a traditional Engine buildup.

Centrifugal Compressors: Paxton blower & turbo

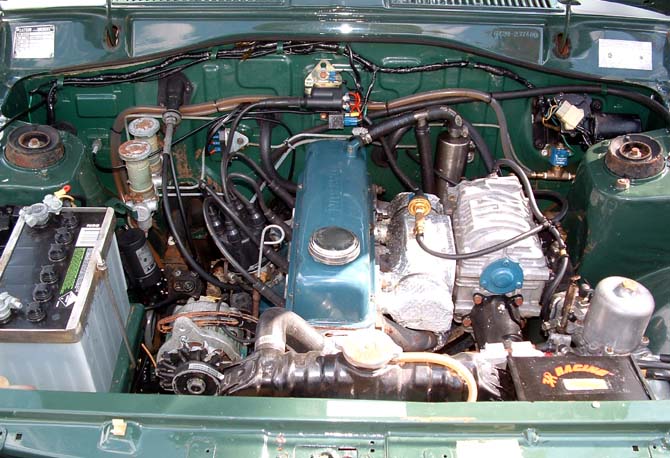

All have been used in Datsun 1200s, as these photos show.

B&M blown A14 (rootes-type supercharger)

B&M blown A14 (rootes-type supercharger)

B&M supercharged NAPS-Z engine (rootes-type blower)

B&M supercharged NAPS-Z engine (rootes-type blower)

Compound Supercharging concept

Compound Supercharging concept

Draw-through vs Blow-through

You can put the carburetor before the blower (draw-through) or after the blower (blow-through). Both work well.

- Draw-through places the carburetor in the normal position (same as naturally-aspirated). A larger carburetor is needed to make more power, and the jetting should be richened up to handle full-throttle operation

- Blow-through places the carburetor in the boost side, so it must be modified to handle this boosted condition. The floats must be non-crushable type, and the carburetor sealed against air leaks. Jetting using calls for radical changes

Engine Build

A stock A12 can make up to 160HP - with stock rods, stock pistons, stock head gasket -- when powered up by a turbo. If the same output is gained by revving the engine higher (naturally aspirated), the rods & pistons must be upgraded. If 160HP is made by Supercharging, the engine should be upgraded with forged pistons and stronger rods to handle the load of the blower.

The most important part of forced induction is Spark Control. If you keep the spark backed off, the engine will not self-destruct. At the most basic this means limiting the distributor Spark Curve.

Spark Curve

The more compression, the less advance the engine can handle. But a high-compression engine can still use some advance, and even a forced-induction engine needs some advance to make the most power at varying RPMs. The key is LIMITING the advance to a safe level.

Consequences of too much spark advance: cracked pistons, broken ring lands

What about locking the distributor? Yes, if you lock the advance mechanism, yes, it can help prevent detonation, but also it won't make the best power. Locked distributor will only work great at high-RPM, high-boost condition -- which is where racers spend most of their time, so it works well for racing. For a street engine, you will have a more flexible, more powerful engine at all RPMs by NOT locking the distributor, but by limiting the advance.

CONSTANT-LOAD RACING METHOD

- Lock the distributor advance. Set full timing to an appropriate level, say 30 degrees for a high-compression engine or for maximum advance at 16 psi boost: 23 degrees.

LOW-DOLLAR STREET POWER METHOD

- In the distributor, weld the advance slots partially to limit mechanical advance (see Limiting Mechanical Advance)

- Keep the stock vacuum advance (it will have no effect under heavy throttle or boost)

- Connect vacuum advance up directly to manifold. This will help idle and starting out under low throttle, but the vacuum advance will have no effect under heavier throttle

- Set initial timing to lower than normal, say 3 degrees or 0 degrees (instead of the normal 5-7)

- Downside: On a forced-induction engine, the advance won't be right for varying boost levels. You'll have to set the advance for full boost scenario, giving up HP and fuel economy for lower throttle conditions such as highway cruising

BEST METHOD: fully programmable ignition

- use a crank trigger with a fully programmable ignition system. MegaSquirt and other ECUs can provide initial timing, limited full timing, timing under boost and even retard under boost and compensate for high temperatures.

- use a standalone advance controller like the Block Box or an MSD Programmable, which allows for limited mechanical advance along with variable retard under boost, off-boost, and partial-boost conditions. With such a controller, the distributor is locked, and the box takes over the exact timing curve.

Intercooler

An intercooler can result in far more HP, but requires a blow-through system (boxed carburetor) or EFI port injection. This is because for safety you don't want air-fuel mixture going through the cooler, where it will condense out of the airstream and result in fuel puddles in the cooler!

By keeping the air cool and therefore dense, the same boost will make more HP, because more air is entering the engine. Because it's not overheated, more spark advance can be applied for more HP.

Boost pressure

- 6-7 psi is what a lot of OEM applications use.

- 10 psi is reliable with a stock A12 or A14

- 14.7 lbs gives theoretically double the airflow so max. power would be about 2x stock, but this isn't actually the result. The reason is that the stock induction and exhaust system won't flow this much air under pressure. However, the low rpm torque could approach 2x (at about 2250 rpm) if a small blower is used. So a 130hp forced induction engine will have much more performance than a 130hp NA engine

Induction and Exhaust

Obvious, to obtain more airflow, a higher flowing carb, intake, heads (ports and valves) and exhaust system is beneficial.

Supercharging will increase power on a stock engine, even one with no mods. But increasing the airflow capability of the engine will bring your blown engine to its full potential.

Rootes

Centrifugal

* Paxton (as of 2016) only makes high-HP blowers (smallest is 775 HP) * Vortech's smallest (V5) is up to 450 hp output * Powerdyne seems out of business

Procharger makes blowers suitable for A-series: * A-1P up to 100 HP is for engines of base 25-75 hp * A1-R up to 150 HP is for 50-95 HP engines * B1 up to 250 HP is for 60-150 HP engines

These are about the size of a large alternator, and have serpentine belt pulleys.

Crank Pulley For Supercharger Drive

The factory pulleys have a bad habit of cracking through the keyway. Use a custom one with a steel crank hub.

http://www.kemotorsport.com Datsun A-SERIES Supercharger pulley 6rib+V $140 posted

Supercharger Setups

Autospeed article: Supercharger Steal - A look at the second-hand superchargers on the market

4AGEZ supercharged from the MR2.

Possum1200

Possum bought this 1200 with dry sump, then sold the blower to revhead

Mercedes

Mercedes blower by Eaton (w/o clutch) | Eaton M45

datsa73

Mercedes Kompressor-boosted Datsun 1200 (with OEM electric clutch)

AMR

Wally

See Wally's Wagon: A Supercharged Super Car with AMR300 blower

AMR500

Made by Aisin. Larger than the tiny AMR300 found on Subarus. Found on Nissan March with MA09S engine

http://www.kemotorsport.com kit for A12

POST A12iR Project (i=injection, R=supercharged) GM sensors AMR500 Supercharger

rogue

AMR300 from Subaru Vivio with EN07Z 660cc-class (kei car) engine

See Main Article: Rogue

SC12

Toyota SC12 supercharger

SC12 1200

See main article: SuperSedan

SC14

Toyota SC14 supercharger is the most popular blower swap for Datsun 1200s.

NZ2DR

Blown A-series 2-dr from New Zealand

Blown 3800

GM V6 with supercharger in Datsun 1200

blown1400

Datsun 1200 Utility Supercharged a14 Ross pistons shot-peened valves, con-rods etc. Water-injected supercharger sucks through a 2-inch SU

Photo Index

See Forced Induction A-series Photo Index

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)