| Revision as of 01:10, 24 September 2007 Ddgonzal (Talk | contribs) (->Pistons) <- Previous diff |

Current revision ddgonzal (Talk | contribs) (->Ventilation) |

||

| Line 1: | Line 1: | ||

| - | [http://datsun1200.com/modules/myalbum/photo.php?lid=770 http://datsun1200.com/modules/myalbum/photos/thumbs/770.jpg] A12 Engine ID Mark | + | The A12 engine of the Datsun 1200 features a modern lightweight cast-iron cylinder block. For an overview of all A-series engines see [[Block Comparison]]. |

| - | == Cylinder Blocks == | + | = Identification = |

| - | * 11010-H2300 A12 BARE BLOCK 73mm/2.87" bore size | + | A12 can be positively identified by looking for the engine Stamped ID. |

| - | * 11010-H9960 A12A BARE BLOCK 75mm/2.95" bore size | + | |

| - | * 11010-H6200 [1974] A13 BARE BLOCK 73mm/2.87" bore size | + | |

| - | * 11010-H9700 A14/A15 BARE BLOCK 76mm/2.99" bore size | + | |

| + | See Main Article: [[Engine ID Mark]] | ||

| - | === Overbore === | + | {{Album!|770}} |

| - | The 1971-1973 A12, the one with the front distributor, can usually be bored to 76mm. This is the same as a stock A14. There are probably some dud blocks around, but generally 76mm is fine. Pistons of 76.5 mm size and larger were offered through the Datsun competition department and others back in the 70's, so it's a factory approved bore size. | + | |

| - | A14 pistons use a 19mm wrist pin while the A12 rods have a 17.5mm hole, so you have choices: | + | = Ventilation = |

| - | * Bore the original rod to 19mm. This is most commonly done | + | Under the block [[Breather Tubes|breather pipe]], this steel mesh separates out the oil vapor from [[PCV|crankcase ventilation]] air. |

| - | * Find a set of late A12 rods. There seems to have been a change in the later rods and these forgings look like they are the ones that were used for the A12A & A13 engines. [more on this later]. These rods have more 'meat' around the pin hole & would be stronger than a 1200 rod after the pin hole was bored to 19mm. | + | <br>{{Album|18283}} {{Album|27096}} |

| - | * Find a set of A12A or 1980's A13 rods as these have the right length and the correct wrist pin hole for the A14 pins | + | |

| + | [[Block_%26_Pan_Part_Numbers|Part Numbers]] | ||

| + | {{searchPart|11037-H1000}} NET-STEEL CRANK CASE A12/A13/A14/A15 | ||

| + | 08310-61214 SCREW-MACHINE (2) | ||

| + | 11038-H1000 PLATE-BAFFLE CRANK CASE A12/A13S | ||

| + | 11038-H6200 PLATE-BAFFLE CRANK CASE A14 EARLY H72 BLOCK | ||

| + | 11038-H9700 PLATE-BAFFLE CRANK CASE A14 LATE + A15 G34 BLOCK | ||

| - | 73mm bore piston used the 17.5mm piston pin diameter: | + | H97 baffle plate |

| - | * A10 | + | <br>{{Album|30364}} |

| - | * 1971-1973 A12 (1200) | + | |

| - | * 1974-up A12 | + | |

| - | * 1974 A13 (tall block engine) | + | |

| - | A series pistons for engines with 75mm bore used a 19mm pin: | + | baffle plate bolts in rear portion of the engine block |

| - | * A12A - USA & Japan only | + | <br>{{UploadPost|174_67b163d1d47cf.jpg|498788}} |

| - | 76mm bore size also used the 19mm pin: | + | 日産 A型 ブロック換気バッフル |

| - | * A14 | + | |

| - | * A15 | + | |

| - | * 1979-'81 (Asia only) | + | |

| - | A12A and late A13s were just bored out A12s, so they had the shorter A12 length rods, but with the bigger pin size. The crankshaft is interchangeable between early A12, late A12, late A13 and A12A. | + | = Dimensions = |

| + | A12 Deck Height is 189.1 mm. A10 engines are 10 mm shorter, and A14 is 15 mm taller. For more details see [[Block Comparison#Dimensions]]. | ||

| - | == Crankshafts == | + | Length is the same for a A-series engine blocks. |

| - | * 12200-H8515 A12/A12A CRANKSHAFT 70mm/2.76" stroke | + | |

| - | * 12200-H5720 A12 COMPETITION CRANKSHAFT 70mm/2.76" stroke | + | |

| - | * 12200-H8915 A13/A14 CRANKSHAFT 77mm/3.03" stroke | + | |

| - | * 12200-G3400 A15 CRANKSHAFT 82mm/3.23" stroke | + | |

| + | {{Album|19202}} | ||

| - | MAIN BEARING (#1/#5, SHELL THICKNESS) | + | = Drain Plug = |

| - | <br>4 each required | + | {{AlbumC|15004|h=50|shape=27205|t=128|l=310}} |

| - | * 12215-H2310 .0720" | + | |

| - | * 12215-H2311 .0718" | + | |

| - | * 12215-H2312 .0715" | + | |

| + | Buy at [http://www.datsun1200.asia/category/select/pid/9244 Bprojects] | ||

| + | [[Block & Pan Part Numbers|08931-30410]] PLUG-TAPER THREAD WATER DRAIN | ||

| + | * Fit all A-series block all years | ||

| + | * Size: 1/4 inch NPT | ||

| + | * Wrench Size: 14mm | ||

| + | * Overall length: 18.5mm | ||

| - | MAIN BEARING (#2/#4, SHELL THICKNESS) | + | {{Album|28804|was=Photo\08931-30410.jpg\Datsun%201200/Parts}} {{Album|28805|was=Photo\08931-30410-.jpg\Datsun%201200/Parts}} |

| - | <br>4 each required | + | |

| - | * 12231-H2310 .0720" | + | |

| - | * 12231-H2311 .0718" | + | |

| - | * 12231-12312 .0715" | + | |

| + | = Head Locating Dowels = | ||

| + | Starting with A12 engine for B210 and including later 1200, dowels were used to locate the [[Cylinder Head]]. | ||

| - | MAIN BEARING (CENTER, SHELL THICKNESS) | + | {{Photo|head_dowels.jpg}} |

| - | <br>2 required | + | |

| - | * 12247-H2310 .0720" | + | |

| - | * 12247-H2311 .0718" | + | |

| - | * 12247-H2312 .0715" | + | |

| + | 11053-73400 DOWEL-BLOCK TO HEAD 14 diameter 2 | ||

| + | = Cylinder Blocks = | ||

| + | Also see: [[Block Comparison]] | ||

| - | == Connecting Rods == | + | The block has ~2.5 liter [[Radiator|coolant capacity]]. |

| - | 4 of each required: | + | |

| - | * 12100-H1000 A12 CONNECTING ROD 121.5mm/4.78" center-to-center | + | |

| - | * 12100-18500 A12A CONNECTING ROD 121.5mm/4.78" center-to-center | + | |

| - | * 12100-16200 [1974] A13 CONNECTING ROD 133mm/5.24" center-to-center | + | |

| - | * 12100-17200 A14/A15 CONNECTING ROD 133mm/5.24" center-to-center | + | |

| + | {{Photo|n59975533yoshi_senna-img600x450-1211090038fvol0413765.jpg}} | ||

| - | ROD BOLT | + | == Original Block == |

| - | The Datsun rod bolt is a true stretch bolt and should be torqued only once. New bolts should be installed at every disassembly. 8 each required: | + | 11010-H2300 A12 BARE BLOCK 73mm/2.87" bore size |

| - | * 12109-H1001 CONNECTING ROD BOLT | + | * running change replaced 11010-H1000 |

| - | * 12112-H1000 CONNECTING ROD NUT | + | |

| + | H10 block castings | ||

| + | <br>{{Album|19179}} | ||

| - | CONNECTING ROD BEARINGS | + | == Redesigned Block == |

| - | The -25720/-H2310 bearing shell produces the most desirable bearing clearance for racing purposes when applied to a standard size crankshaft. The other shells exist in order to obtain proper clearance when compensating for the variations in the crankshaft or connecting rod journals. | + | * 11010-H5000 A12 [[B120]] From July 1973 (?) |

| + | * 11010-G1600 A12 B120 From June 1975 (?) | ||

| + | * 11010-G1618 A12 B120 7908-8503 | ||

| + | * 11010-G1619 A12 B120 8504- (M79 casting) | ||

| - | 8 each required: | + | H50 casting, from 1974-1985(?) Datsun 1200 |

| - | * 12111-25720 .0590" | + | <br>{{Album|20516}} |

| - | * 12111-25721 .0588" | + | |

| - | * 12111-25722 .0585" | + | |

| - | * 12111-25723 .0592" | + | |

| - | * 12111-25724 .0583" | + | |

| - | == Pistons == | + | M79 casting, from 1985-1994 Datsun 1200 |

| + | <br>{{Album|21287}} {{Album|21288}} | ||

| + | |||

| + | = Overbore = | ||

| + | The 1971-1973 A12, the one with the front distributor, can usually be bored to 76mm. This is the same as a stock A14 and will increase HP much more than going to high compression. | ||

| + | |||

| + | See main article: [[Bored And Stroked]] | ||

| + | |||

| + | = Crankshafts = | ||

| + | A12 uses a forged crankshaft, so it is plenty strong -- even for 8500 RPM use. | ||

| + | |||

| + | Stroke: 70mm (2.76 in.) | ||

| + | |||

| + | For more details and part numbers, see [[Crankshaft]] | ||

| + | |||

| + | = Connecting Rods = | ||

| + | Stock A-series rods are forged, and will last a lifetime in a stock or moderately upgraded performance engine. There is no need to use a heavier duty rod unless you are using a high boost turbo or supercharger, or revving higher than 8500 RPM. | ||

| + | |||

| + | See main article: [[Connecting Rods]] | ||

| + | |||

| + | {{Album!|15725}} | ||

| + | |||

| + | = Pistons = | ||

| A12 engine came with dished pistons for approximately 9.0:1 compression ration. Standard bore size for the A12 or A13 block is 73mm/2.874". Pistons are cast. Nissan Competition does not recommend forged pistons for street use. | A12 engine came with dished pistons for approximately 9.0:1 compression ration. Standard bore size for the A12 or A13 block is 73mm/2.874". Pistons are cast. Nissan Competition does not recommend forged pistons for street use. | ||

| + | See Main Article: [[Piston]] | ||

| - | See main article: [[Piston]] | + | = Main Bearing Caps = |

| + | Also see: [[ARP]] | ||

| + | [[Block & Pan Part Numbers|12293-18001]] BOLT-MAIN BEARING CAP (10) L=72.5 <> 12293-01M00 | ||

| + | * A12/A14/A15 engine (quantity 10) | ||

| + | * L16, L18 and L20B engine (10) | ||

| + | * 720,D21,S110 with Z20/Z22/Z24E/Z24I (10) | ||

| + | * 910,S130 with L24/L28E (14) | ||

| + | * B11, N10/N12 with E15/E16 (10) | ||

| + | * D21 PICKUP with KA24E engine (10) | ||

| + | {{UploadPost|174_5ac95f2837b42.jpg|488014}} | ||

| - | [[Category:Engine Mechanical]] | + | [[Category:Engine Mechanical]]{{End}} |

Current revision

The A12 engine of the Datsun 1200 features a modern lightweight cast-iron cylinder block. For an overview of all A-series engines see Block Comparison.

Contents |

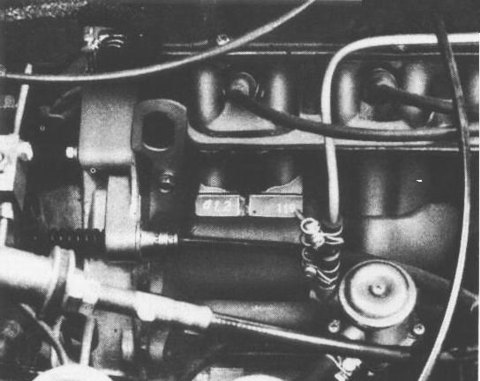

Identification

A12 can be positively identified by looking for the engine Stamped ID.

See Main Article: Engine ID Mark

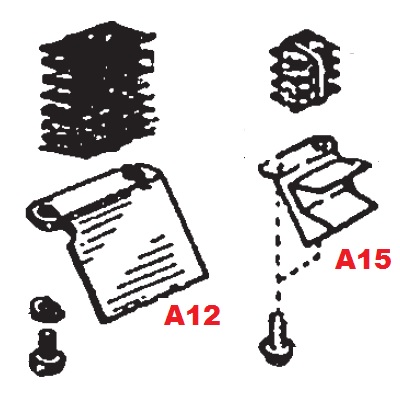

Ventilation

Under the block breather pipe, this steel mesh separates out the oil vapor from crankcase ventilation air.

Part Numbers 11037-H1000ᴳ NET-STEEL CRANK CASE A12/A13/A14/A15 08310-61214 SCREW-MACHINE (2) 11038-H1000 PLATE-BAFFLE CRANK CASE A12/A13S 11038-H6200 PLATE-BAFFLE CRANK CASE A14 EARLY H72 BLOCK 11038-H9700 PLATE-BAFFLE CRANK CASE A14 LATE + A15 G34 BLOCK

baffle plate bolts in rear portion of the engine block

日産 A型 ブロック換気バッフル

Dimensions

A12 Deck Height is 189.1 mm. A10 engines are 10 mm shorter, and A14 is 15 mm taller. For more details see Block Comparison#Dimensions.

Length is the same for a A-series engine blocks.

Drain Plug

Buy at Bprojects 08931-30410 PLUG-TAPER THREAD WATER DRAIN * Fit all A-series block all years * Size: 1/4 inch NPT * Wrench Size: 14mm * Overall length: 18.5mm

Head Locating Dowels

Starting with A12 engine for B210 and including later 1200, dowels were used to locate the Cylinder Head.

11053-73400 DOWEL-BLOCK TO HEAD 14 diameter 2

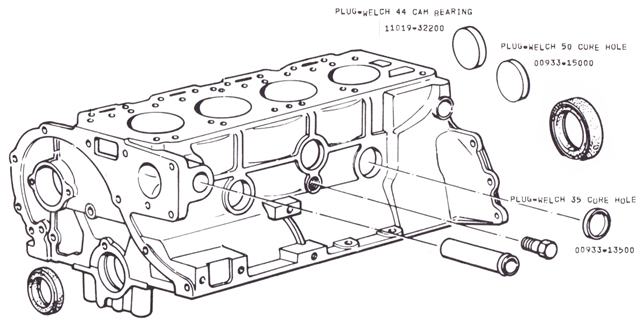

Cylinder Blocks

Also see: Block Comparison

The block has ~2.5 liter coolant capacity.

Original Block

11010-H2300 A12 BARE BLOCK 73mm/2.87" bore size * running change replaced 11010-H1000

Redesigned Block

* 11010-H5000 A12 B120 From July 1973 (?) * 11010-G1600 A12 B120 From June 1975 (?) * 11010-G1618 A12 B120 7908-8503 * 11010-G1619 A12 B120 8504- (M79 casting)

H50 casting, from 1974-1985(?) Datsun 1200

M79 casting, from 1985-1994 Datsun 1200

Overbore

The 1971-1973 A12, the one with the front distributor, can usually be bored to 76mm. This is the same as a stock A14 and will increase HP much more than going to high compression.

See main article: Bored And Stroked

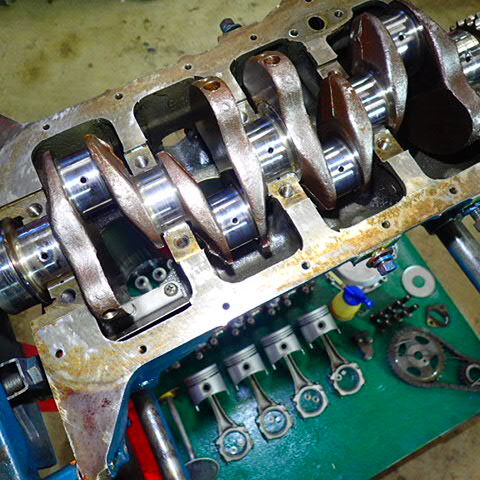

Crankshafts

A12 uses a forged crankshaft, so it is plenty strong -- even for 8500 RPM use.

Stroke: 70mm (2.76 in.)

For more details and part numbers, see Crankshaft

Connecting Rods

Stock A-series rods are forged, and will last a lifetime in a stock or moderately upgraded performance engine. There is no need to use a heavier duty rod unless you are using a high boost turbo or supercharger, or revving higher than 8500 RPM.

See main article: Connecting Rods

Pistons

A12 engine came with dished pistons for approximately 9.0:1 compression ration. Standard bore size for the A12 or A13 block is 73mm/2.874". Pistons are cast. Nissan Competition does not recommend forged pistons for street use.

See Main Article: Piston

Main Bearing Caps

Also see: ARP

12293-18001 BOLT-MAIN BEARING CAP (10) L=72.5 <> 12293-01M00 * A12/A14/A15 engine (quantity 10) * L16, L18 and L20B engine (10) * 720,D21,S110 with Z20/Z22/Z24E/Z24I (10) * 910,S130 with L24/L28E (14) * B11, N10/N12 with E15/E16 (10) * D21 PICKUP with KA24E engine (10)

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)