Datsun 1200 Tune-Up overview. For all the details, pictures, etc. get a Repair manual (maintenance book). It will pay for itself. Don't leave home without one!

Also see: Periodical Maintenance and Lubrication Schedule

Contents |

[edit]

Note

- I suggest buying new points/condensor each year

- I suggest not buying any new plugs/wires/cap/rotor unless inspection shows they are definitely bad, they can last for decades. Usually just a cleanup of the part is needed.

- IMPORTANT: Part of the tuneup should be a close inspection of the vacuum hoses and vacuum motors on the carburetor.

[edit]

Summary

- Adjust clutch pedal

- Hydraulic clutch adjustment: On transmission: 1-2 mm play. Inside: pad height (153-159 mm from floor). Then check pedal free play -- it must have free play to avoid burning out the clutch -- check with fingertips). Pedal play is 11-15mm

- Mechanical Cable clutch (non-US models): On transmission: 3-4 mm play. Inside: pad height (136.5-146.5 mm from floor). Then check pedal free play -- it must have free play to avoid burning out the clutch -- check with fingertips). Pedal play is 11-15mm

- Pack Wheel bearings. Carefully adjust.

- Adjust Rear Brakes (manually), then Handbrake. Jack up rear wheel, tighten post until wheel won't turn, turn back one notch. Lubricate handbrake bushing.

- Per schedule, change Fluids: oil & oil filter, fuel filter, engine coolant

- Lubricate suspension, steering linkage and driveshaft

- Check fluid levels: oil, coolant, gearbox, differential, battery, brakes, clutch, steering box

- Inspect coolant hoses for extreme softness, leaking or cracks. Tighten clamps.

- Visually inspect Engine for fluid leaks (antifreeze and oil and gasoline)

- Check fuel lines and connections for leaks

- Check hydraulic (Brakes and Clutch) lines and connections for leaks

- Check tire pressures when cold (driving less than 1 mile). Bias 12s: 22psi front and rear (radial 12s: 24psi)

- Inspect drive belts. Adjust belt tension to 1/2 inch play.

- Inspect Throttle Linkage (the cable often breaks on aged 1200s). Lubricate moving points and cable. Lubricate/clean carburetor linkage and moving parts, throttle and choke shafts.

- Steering Linkage: (check for play, lubricate)

- Lubricate Hood (bonnet) latch and trunk (boot) lid latch. Grease with molybdenum disulphide grease

- Door, hood, tailgate and trunk hinges: 1-2 drops of oil

- Door striker plates: non-stain stick lube

- Key lock cylinders: use key lock lube on key, insert and turn. Repeat several times until smooth operation is acheived.

[edit]

Engine TUNE-UP

Discussion: Tune-up Q&A's

- Torque head bolts cold. Re-torque cylinder head bolts in sequence (inner first, working to outer bolts). Adjust cold to:

- A12 (to engine number A12-470084) 33-36 ft lb (4.5-5.0 mkg)

- A12 (newer) 40-43 ft lb (5.5-6.0 mkg)

- Adjust valves

- Ignition

- Clean and gap plugs to 0.035 inch

- Clean cap with cloth and dish soap water. Thoroughly dry. Scrape terminals clean inside as well as rotor edge

- Inspect spark plug wires. Replace those with burns or cracks

- Lube distributor cam with cam lubricant. Adjust contact points dwell (49-55 degrees). New points can be gap-set to 0.018-0.021 inch (0.45-0.55 mm)

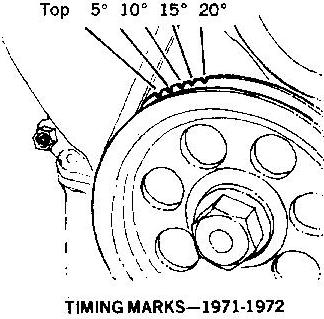

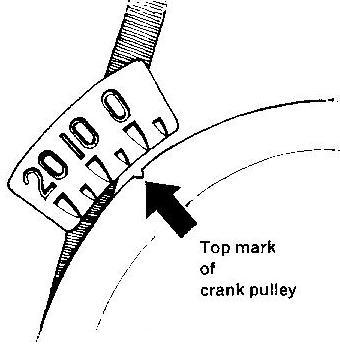

- Set timing to 5 degrees BTDC (or per chart below). Disconnect and plug vacuum advance line while checking (see Ignition Timing)

- If the engine doesn't run perfectly well, do a Compression Test. Normal range is 120-155 lbs. The four cylinders shouldn't vary by more than 5-10 pounds each.

- Inspect induction system -- before adjusting idle and mixture! See Vacuum Leaks

- Inspect all vacuum hoses for cracks and possible leaks

- Test all vacuum diapragams for leaks, including EGR valve, choke opener (vacuum break), throttle opener, etc. Generally, pull hose off, move vacuum motor with finger or screwdrive, then put finger on inlet. It should stay in position (at least partially) and make suck air noise when you take your finger off. Replace if it won't hold vacuum. These can be plugged without affecting driveability: EGR, throttle opener, air clean heat air flap (though if this doesn't work, possible carburetor icing below 39 F)

- Test ATC air cleaner valve (bi-metal valve) - it should leak only a little vacuum

- PCV system: check air filter in air cleaner housing. Unscrew valve from intake manifold. Clean valve with carb cleaner, make sure valve moves freely

- Air Filter: hold up to light or sunlight. If light cannot be seen through, replace filter. Also check air-pump filter (if equipped)

- Inspect and lubricate air Heat Riser (in exhaust manifold). Verify it opens fully. When cold there should be light tension holding it closed

- Check carburetor cold-engine settings

- Adjust choke so it just barely closes when completely cold

- Start engine and adjust fast-idle cam speed (say, 1500 rpm, or whatever seems to work well)

- Inspect carb fuel level through glass window. If it is low or high, adjust the float level (see the Carburettor Diagnosis article)

- Verify choke completely opens when engine is warm

- If it doesn't fully open, see Choke

- Adjust carburetor at full operating temperature. Verify choke is fully open before adjusting

- See Carburetor Adjustment

- 1973 (all models). : 800 rpm leanest smooth idle

- automatic. . . . . (check for 650 rpm in drive after adjustment)

[edit]

Datsun 1200 & B210 Tune-up Specifications (North America Models)

Since you may be running a newer engine in your Datsun 1200, it is good to have the specifications here.

| Valve Clearance | 0.014 in (0.35mm) HOT | ddgonzal's tip: to adjust cold, use .001 smaller gap |

| Spark Plug Type | 1971 | NGK BP6E |

| 1972-1976 | NGK BP5ES | |

| 1977-1978 US models - except 5-speed trans | NGK BP5ES-11 (standard)

NGK BP4ES-11 (hot) | |

| 1977-1978 US models - 5-speed transmission | NGK BP5EQ-11 (standard)

NGK BP4EQ-11 (hot) | |

| 1977-1978 Canadian models | NGK BPR5ES (standard)

NGK BPR4ES (hot) | |

| Spark Plug Gap | 1200 | 0.028-0.032 in. (0.7-0.8 mm) |

| 1974-1976 B210 | 0.031-0.035 in. (0.8-0.9 mm) | |

| 1977 B210 - US models | 0.039-0.043 in. (1.0-1.1 mm) | |

| 1977 B210 - Canadian models | 0.031-0.035 in. (0.8-0.9 mm) | |

| 1978 B210 - non-California 5-speed | 0.043-0.051 in. (1.1-1.3 mm) | |

| 1978 B210 - other US models | 0.039-0.043 in. (1.0-1.1 mm) | |

| 1978 B210 - Canadian models | 0.031-0.035 in. (0.8-0.9 mm) | |

| Distributor | points distributor | 0.018-0.021 in (0.45-0.55 mm) |

| Dwell Angle | 49-55 degrees | |

| Reluctor Air Gap (elec. distributor) | 0.008-0.016 in (0.2-0.4 mm) | |

| Ignition Timing | 1971-1973 A12 | 5 degrees BTDC |

| 1974 A13 | 5 degrees BTDC | |

| 1975-1976 A14 - Manual transmission | 10 degrees BTDC | |

| 1975-1976 A14 - Auto California | 8 degrees BTDC | |

| 1975-1976 A14 - Auto 49-state | 10 degrees BTDC | |

| Idle Speed | 1971-1972 A12 manual | 750 best idle, then lean to 700 rpm |

| 1971-1972 A12 automatic | 780 best idle, then lean to 750 rpm

(check for 600 rpm in drive) | |

| 1973-1974 A12 & A13 (all models) | 800 rpm leanest smooth idle

automatic : (check for 650 rpm in drive) | |

| 1975-1976 A14 manual | 765 best idle, then lean to 700 rpm

Peform adjustment with air pump check valve disconnected and capped | |

| 1975-1976 A14 automatic | 670 best idle, then lean to 650 rpm

| |

| Tire Pressures | B110 - 6.00-12 | 22 psi |

| B110 - 155SR-12 | 24 psi | |

| B210 - 6.15-13 | 24 psi | |

| B210 - 155SR-13 | 24 psi | |

| Lubricants | Engine | SD or SE rating

40W - above 60 F (15 C) |

| Manual transmission | API GL-4

80 weight - below 90 F (30 C) | |

| Automatic transmission | Dexron | |

| Differential | API GL-5 | |

| Brake and clutch | DOT 3 or DOT 4 | |

| Refill Capacities | A12 Engine Oil w/filter | 3.5 qt (3.3 liter) |

| A13 Engine Oil w/filter | 3-3/8 qt (3.2 liter) | |

| A14 1975 | 4-1/8 qt (3.9 liter) | |

| A14 1976 | 3-7/8 qt (3.6 liter) | |

| A12-A13 Oil wo/filter | 2-7/8 qt (2.7 liter) | |

| A14 1975 Oil wo/filter | 3-5/8 qt (3.4 liter) | |

| A14 1976 | 3-3/8 qt (3.2 liter) | |

| 4-speed 71-74 | 2.5 pt (1.2 liter) | |

| 4-speed 75 up | 2-3/4 pt (1.3 liter) | |

| 5-speed | 3-5/8 pt (1.7 liter) | |

| Differential 1200 | 1-5/8 pt (0.75 liter) | |

| Differential B210 | 1-7/8 pt (0.9 liter) | |

| Steering gearbox 1200 | 1/2 pt (0.24 liter) | |

| Steering gearbox B210 | 5/8 pt (0.27 liter) |

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)