Speedometers were either in kilometers (JDM) or miles (USA). Australia started with mph and then switched to kph. Some speedometers had a trip meter.

1972 USA Owners manual (see page 8,9 for Speedometer):

Instrument and Controls

Contents |

Variations

- ?? 100MPH w/o tripmeter (US standard equipment)

- ?? 100MPH with tripmeter

- 24850-H3400 1200 120MPH SPEEDOMETER Includes tripmeter

- Facelift GX - 180 kph

Part Numbers

USA

- 24850-H1816 ASSY-SPEEDOMETER 100MILE/H

- 24850-H7000 ASSY-SPEEDOMETER 100MILE/H From 7/72 [With 10 mph markings]

JDM Sunny Truck

- 24850-B8600 SPEEDOMETER ASSY -7803 [Rectangle]

- 24850-G1670 SPEEDOMETER ASSY 7804- [Round]

Metric-Imperial Conversion

Sometimes on eBay Australia you can get the vintage conversion stickers.

OR

Take the face plate and scan it on the flatbad scanner, then modify it. Finally, print a new one out with the photo printer. You can modify the font, colors, etc. Bolt it to the speedo using the standard screws.

Speedometer Calibration

There are two basic reasons for speedos reading fast or slow:

- Factory speedometer tolerance is usually 5% fast to 10% slow (this is in general, I don't know what Nissan's specs are)

- 1200 Top Speed discusses this. One magazine test noted the 1200 speedometer in the test car was 7% slow. My 1200s have been between 7.5% - 10% slow (with stock running gear include tire size). Also see speedo off

- Different size tires than original, changed diff ratio or transmission

For the latter, there is a mechanical solution of changing to the appropriate speedo-drive gear at the back of the transmission:

For the former, where you have the "right" size tires, final gear ratio and stock transmission -- the speedometer itself may be calibrated.

Odometer Calibration

Before messing with the mechanism, make sure the odometer (distance counter) is correct. If it is not, different transmission-to-speedometer cable pinion gears are called for.

Get on the highway and drive. As you pass the mile markers note the indicated milage. A 10 mile drive is good for accuracy. If the odometer reads 10.0 miles it is perfect. But if it read 11.0 mile it is running 10% off.

- Change the pinion gear to correct.

- Or, change tire size (diameter) to correct.

- Or, use a speedometer adapter ratio adapter at about $150

Once you get the odometer reading correctly, then move to confirm the speed needle readings.

Mechanism Calibration

Where can you go to get a speedo calibrated? Can it be done at home?

Assuming your odometer reading is now verified correct, proceed to calibrating the needle reading.

You can:

- Change the pointer position. This is good if the speedometer is off by say 2mph at all speeds.

or

- Change the magnetic tension. This will adjust the scale across the board. Be careful as it is easy to ruin it

- For ideas, see: Recalibration of Speedometer

Bench Test

You can turn the speedometer cable with an electric drill. As long as you have a way to adjust it to run at a steady speed, you can test it versus the odometer.

Parts needed:

- reversible electric drill to drive the speedo cable

- 500W dimmer switch to vary constant drill speed

- 60W light bulb (dimmer requires this)

- Extension box

- Outlet plug

- Electric wiring

NOTE: Danger. Use caution and properly grounded and boxed connections. Do not attempt at home. Use professional equipment.

A typical reversible electric drill may run at 2500 RPM. The speedometer is 50mph=1024 rpm, so turn the Dimmer down about 1/3 from full to start.

Pull trigger fully to run drill at constant speed. Then vary the dimmer switch to show 60mph.

With a stop watch, time exactly 60 seconds. If the odometer moves exactly 1.0 miles it is good. If you are not sure, run for three minutes. If it shows 3.0 miles it is perfect. Otherwise record the reading.

Repeat for 30 mph and 90 mph.

Calculate the MPH difference at each speed.

Road Test

- Compare against roadside radar box

- Timing test. Go out on highway and drive at steady mph while you time the mileposts.

- 10 miles 60 mph should take exactly 10 minutes

- 5 miles 30 mph should take exactly 10 minutes

Compare both a high and low speed.

Adjustment

- If all reading are off by a fixed MPH, carefully move the needle to correct it.

- If the readings get worse the faster it goes, the mechanism needs calibration.

- NOTE: haven't tried this yet. Don't know how well it works

- Adjust pointer so 30 mph reading is correct

- If 90 mph reading is now incorrect, adjust cup drive

Changing Scale

You can easily change the scale to make it read correctly, or to make a 180 kph scale. The downside is that the odometer (distance counter) will be inaccurate.

- Scale Adjusted for low gearing, looks good printed on photo paper and bolted to speedometer.

- Use a light, removable contact cement. Otherwise if you just tack the edges or a places, the photo will eventually buckle and warp and interfere with the needle movement.

- I modified mine to change the scale since I didn't want to get under the car and change the plastic speedo gears.

Amplifier Speed Switch

USA model from 0772 use an amplifier speed switch.

25035-H7000 ASSY-AMPLIFIER SPEED SWITCH

Australia models also used it, dates unknown.

Custom Faces

- Swap the mounting cups as the 280Z unit is deeper

- Drill a hole for the trip meter shaft through the back

- The face is to large for the opening in the 1200 housing, so carefully reduce the diameter by 1/8 inch

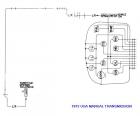

Speedometer Cable

The cable for manual transmission and Automatic are different

Rockauto.com $7.76

Nissan Part Numbers

B10 25058-89914 ASS'Y-SHAFT, flexible speedometer B10 M/T 25058-89915 ASS'Y-SHAFT, flexible speedometer B10 Automatic

B110 - both interchange 25058-H1000 ASS'Y-SHAFT, flexible speedometer Length=1500 NLA 25058-H1001 ASS'Y-SHAFT, flexible speedometer Length=1400 NLA

B210 25050-H5000 ASS'Y-SHAFT, flexible speedometer Length=1700 A12 * B5050-Y8101 supercedes 25050-H5000 $51.22 25050-H5900 ASS'Y-SHAFT, flexible speedometer Length=1650 w/Master Vac NLA 25050-H7403 ASS'Y-SHAFT, flexible speedometer w/63-series trans 25050-H7410 ASS'Y-SHAFT, flexible speedometer A14 automatic 25050-H7411 ASS'Y-SHAFT, flexible speedometer A12 late

Cable Breaks

The speedometer cable usually lasts forever. There are two common reasons why it will break:

- Mechanical kink or breakage, for example if you drive over a tree branch and it pulls the cable

- Bad or missing engine ground wire.

Additional reasons * Lack of grease * Break in cable allows water which freezes in winter

I think you'll find this is caused by poor/dirty ground strap from the engine to the body inside the engine bay.It only takes once, and the cable it screwed, as it melts the nice polyethylene coating on the inside.

See how the cable's protective plastic appear worn..I'd say it melted during starter crank. Then when the cable gets some speed up, the plastic grabs and the cable snaps.

Drive Ratios

Stock 1200 Speedometer gear ratio:

- pinion teeth/worm teeth on trans output shaft

- 17/5 (3.90 diff)

- 18/5 for Wagon or Ute (4.11 diff)

To adjust the speedometer for different diameter tires, change the transmission cable pinion cog.

* If speedo reads too fast, fit a bigger cog * If speedo reads too slow, fit a smaller cog

Given that stock is a 17 tooth pinion, moving to one more or less tooth is about 6% change. So by changing the pinion you can only get it to ±3 mph accurate. For example, at 100 mph, within 3 mph. Or at the standard 50 mph rating, a reading between 1½ mph (48½ to 51½) is the best you can hope for. For finer tuning the speedometer itself needs calibration. Or you could fit different diameter rear tires.

EXAMPLE: If you are reading say 60 when you are really going 50 then the speedo cable needs to slow down by about 20% to read more accurately. If the speedo drive has a 17 tooth cog in it try to find a cog that reduces by 20%. 17 X .20 = 3.4 teeth... 17 + 3.4 = 20.4 teeth, the closest is a 20 tooth cog.

| Teeth | % change | 50 mph reading |

| 16 | 106.25% | 53.1 |

| 17 | 100.00% | 50.0 |

| 18 | 94.44% | 47.2 |

| 19 | 89.47% | 44.7 |

Correction Table, increase Teeth by:

| Actual mph | Desired mph | Tooth |

| 40 | 50 | 3+ |

| 43 | 50 | 2+ |

| 47 | 50 | 1+ |

| 50 | 50 | 0+ |

Estimated Tire Correction Table (for 3.9 diff)

| Size | Diameter | Difference | Pinion | ~Error |

| 165/55R12 | 19.1 | 88% | 19T | 0% |

| 165/60R12 | 19.8 | 91% | 18T | -2% |

| 165/70R12 | 21.1 | 97% | 17T | 3% |

| 155/80R12 | 21.8 | 100% | 17T | 0% |

| 175/70R13 | 22.6 | 104% | 16T | 2% |

| 195/50R15 | 22.7 | 104% | 16T | 2% |

| 165/70R14 | 23.1 | 106% | 16T | 0% |

| 205/45R17 | 23.5 | 108% | 16T | -2% |

| 185/60R15 | 23.7 | 109% | 16T/15T | 3% |

| 205/40R18 | 24.5 | 112% | 15T | 0% |

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)