| Revision as of 06:32, 29 November 2018 racer135 (Talk | contribs) (->A10 Flywheel) <- Previous diff |

Current revision ddgonzal (Talk | contribs) (->Bolts) |

||

| Line 6: | Line 6: | ||

| = Overview = | = Overview = | ||

| - | All flywheels for A-series engines interchange -- for rear-wheel drive vehicles. Differences are the A12 flywheel weighs 2.2 lbs (1 kg) less than the A14/15 flywheels, and is also thinner. | + | All flywheels for A-series engines interchange — for rear-wheel drive vehicles. |

| + | * In 1974 flywheel bolts changed from British Threads to Metric threads. So the bolts are not interchangeable from early to late. See [[Crankshaft#Flywheel_Bolts]] for details. | ||

| + | * The A12 flywheel weighs 2.2 lbs (1 kg) less than the A14/15 flywheels | ||

| + | * A12 flywheel is thinner than A14/A15 and thicker than A10 — this affects the clutch functionality. See [[#Thickness]] | ||

| - | {{Album|23641}} {{Album|17232}} | + | {{Album|17232}} |

| - | A10 8.0 kg (17.6 pounds) | + | A10 12310-18001: 8.0 kg (17.6 pounds) |

| A12 12310-H1000: 9.5 kg (20.8 pounds) | A12 12310-H1000: 9.5 kg (20.8 pounds) | ||

| A12 12310-H2310: 6.4 kg (14.1 pounds) GX, also sold as 'Race Option' | A12 12310-H2310: 6.4 kg (14.1 pounds) GX, also sold as 'Race Option' | ||

| A14 12310-H7200: 10.7 kg (22.3 lbs) | A14 12310-H7200: 10.7 kg (22.3 lbs) | ||

| - | |||

| - | A14/A15 flywheel is thicker than the A10/A12 flywheel. When fitting the thinner flywheel to A14, remove the [[Engine Plate]] to compensate. | ||

| - | |||

| - | A10: 25 mm thick? (does not fit A12 due to different gear angle) | ||

| - | A12: 28 mm thick (fits A10) | ||

| - | A14: 30 mm thick | ||

| {{Album|15048}} {{Album|3152}} | {{Album|15048}} {{Album|3152}} | ||

| - | In 1974 flywheel bolts changed from British Threads to Metric threads. So the bolts are not interchangeable from early to late. See [[Crankshaft]] for details. | + | A12 FLYWHEEL MEASUREMENTS |

| - | + | [[#Thickness]]: 28mm | |

| - | A12 Flywheel Measurements: | + | |

| - | thickness: 28mm | + | |

| ring gear + backing: 20mm | ring gear + backing: 20mm | ||

| back rim to flywheel face depth: 5mm | back rim to flywheel face depth: 5mm | ||

| Line 33: | Line 28: | ||

| starter ring gear | starter ring gear | ||

| <br>{{Album|20430}} | <br>{{Album|20430}} | ||

| + | |||

| + | = Thickness = | ||

| + | A14/A15 flywheel is thicker than the A10/A12 flywheel. When fitting the thinner flywheel to A14, remove the [[Engine Plate]] to compensate. | ||

| + | |||

| + | Mixing/matching flywheels can affect clutch functionality. You may need to use a different size clutch [[Release_Bearing#Bearing_Sleeve|release bearing sleeve]], or change the '''engine plate'''. | ||

| + | |||

| + | A10: 25 mm thick? | ||

| + | * does not fit A12 due to different starter gear angle | ||

| + | A12: 28 mm thick (fits A10) | ||

| + | ???: 30 mm thick (early A14? machined A14?) | ||

| + | A14: 35.6 mm thick (H89 flywheel) | ||

| + | A15: 35.6 mm thick (H89 flywheel) | ||

| + | |||

| + | A15/A14 flywheel | ||

| + | <br>{{UploadPost|174_618a109adaffc.jpg|496146}} | ||

| + | |||

| + | 30mm flywheel thickness | ||

| + | <br>{{Album|23641}} | ||

| = Inspection = | = Inspection = | ||

| Line 51: | Line 64: | ||

| <br>{{Album|23604}} | <br>{{Album|23604}} | ||

| - | Less effective type of stop, can be used in a pinch using a scrap of metal. The bolt will bend while bolting or unbolting the flywheel | + | A less effective type of stop can be used in a pinch using a scrap of metal. The bolt will bend while bolting or unbolting the flywheel but no worries, just toss out the bolt when finished |

| <br>{{Album|23490}} | <br>{{Album|23490}} | ||

| - | Installation - torque the bolts in a star pattern | + | Clean the [[#Bolt]] threads -- do not oil the threads -- and use a torque wrench to install. |

| + | |||

| + | TORQUE SPECS | ||

| + | Flywheel bolts 88 Nm (58-65 ft. lb.) | ||

| + | |||

| + | Installation - torque the bolts in a star pattern (tighten opposite bolts) | ||

| <br>{{Album|23498}} | <br>{{Album|23498}} | ||

| - | When installing the [[Clutch]], use a spline-aligner so the transmission will slide on | + | When installing the [[Clutch]], use a spline-aligner so the transmission will be able to slide on |

| <br>{{Album|23560}} | <br>{{Album|23560}} | ||

| Line 83: | Line 101: | ||

| = Bolts = | = Bolts = | ||

| - | Nissan flywheel bolts are very strong. Just clean the threads and use a torque wrench to install. ARP does not make A-series flywheel bolts (though some use non-A-series ARP bolts on the A-series). In any case the stock bolts are plenty strong. | + | '''Nissan flywheel bolts are very strong.''' Just clean the threads and use a [[Tools#Torque_Wrench|torque wrench]] to install. |

| - | For bolt part numbers, see [[Crankshaft#Flywheel_Bolts|Flywheel Bolts]] | + | THREAD TYPE |

| + | 1966-1973 3/8" x 24 UNF | ||

| + | 1973-2002 M10 x 1.25 (from 1973 July) | ||

| + | |||

| + | TORQUE SPECIFICATION [[1973_USA_Service_Manual#EM33|1973]] | ||

| + | 6.5 to 7.5 [[kg-m]] (47 to 64 [[ft-lb]]) | ||

| + | |||

| + | {{SeeEx|Crankshaft#Flywheel_Bolts|Flywheel bolt part numbers}} | ||

| Best practices: | Best practices: | ||

| - | * Reusing the flywheel bolts is acceptable. Even new bolts will come loose due to shaking. Even ARP bolts will snap! | + | * Reusing the flywheel bolts is acceptable. Even new bolts will come loose due to shaking. Even [[#High_Strength_Bolts|#ARP bolts]] will snap! |

| - | * To reduce vibrations, always re-balance the engine after changing rods or pistons or crank | + | * Do not oil the bolts. Just clean them |

| - | * For 7000+ rpm use have the flywheel doweled. Loctite is not needed. | + | * Overtightening weakens them. Always use a torque wrench |

| - | * Make sure the flywheel-to-flange surfaces are clean. Do not let oil or Loctite get between the two, or the bolts may loosen over time. Do not oil the bolts. Using Loctite threadlocker (red) on the bolts is recommended, apply to the crank threads using a cotton swab instead of putting it on the bolts | + | |

| - | * Overtightening weakens them. Always use a torque wrench. | + | |

| * Use stock Datsun flywheel bolts. If using aftermarket bolt, ensure they are 1) not too long and bottoming out 2) ensure the head face shoulder design is compatible 3) Use high strength steel like the factory bolts 4) Ensure head size does not interfere with the clutch plate | * Use stock Datsun flywheel bolts. If using aftermarket bolt, ensure they are 1) not too long and bottoming out 2) ensure the head face shoulder design is compatible 3) Use high strength steel like the factory bolts 4) Ensure head size does not interfere with the clutch plate | ||

| + | * Loctite is not needed, even for high RPM use. Per {{web|pitroad.works/A-parts-2/clutch2.htm|Pitroad}}: "Pitroad tightens ... without applying screw locking agent." | ||

| + | * Make sure the flywheel-to-flange surfaces are clean | ||

| + | ** Do not let oil or Loctite get between the two, or the bolts may loosen over time | ||

| + | ** Run your finger over the flange. Any burring or uneveness can cause the flywheel to vibrate and come loose over time | ||

| + | * For 7000+ rpm use have the flywheel [[#Dowels_for_High_RPM|#doweled]] | ||

| + | * To reduce vibrations, always re-balance the engine after changing rods or pistons or crank | ||

| - | If using high RPM, look at getting the crank flange dowelled. The flywheel is actually clamped on the head of the bolt not on the shank of the bolt (there is side-to-side play), so three dowels 120° apart should do the job. The end of the crank is soft (unlike the crank journals) and easy to drill. | + | == High Strength Bolts == |

| + | ARP does not make A-series flywheel bolts (though some use non-A-series ARP bolts on the A-series). In any case the stock bolts are plenty strong. | ||

| - | Also see: [[Harmonic Balancer]] | + | That being said, Pitroad sells ARP bolts they have selected and verified for the A-series engine. |

| - | For 7000+ rpm use have the flywheel doweled | + | Pitroad-ARP flywheel bolts |

| + | <br>{{Album|28556}} | ||

| + | |||

| + | TORQUE for extra-strength bolts | ||

| + | 10.0kg-m to 13.5kg-m | ||

| + | {{web|pitroad.works/A-parts-2/clutch2.htm|Pitroad}}: "Tightening torque 13.5kg-m Apply [[Loctite|screw locking agent]] without applying oil to the screw part. However, Pitroad tightens with a tightening torque of 10.0 kg-m without applying screw locking agent." | ||

| + | |||

| + | == Dowels for High RPM == | ||

| + | For 7000+ rpm use, have the flywheel doweled and consider replacing the stock crankshaft pulley with a [[Harmonic Balancer]] | ||

| <br>{{Album|7372}} | <br>{{Album|7372}} | ||

| + | |||

| + | Some recommend Using [[Loctite]] threadlocker (red) on the bolts, though other racing shops say it is not necessary. If use, apply to the crank threads using a cotton swab instead of putting it on the bolts. | ||

| + | |||

| + | If using high RPM, look at getting the crank flange dowelled. The flywheel is actually clamped on the head of the bolt not on the shank of the bolt (there is side-to-side play), so three dowels 120° apart should do the job. The end of the crank is soft (unlike the crank journals) and easy to drill. | ||

| = A10 Flywheel = | = A10 Flywheel = | ||

| A10 engine flywheel is lighter than A12 flywheel, so will not smooth out the power pulses as well. | A10 engine flywheel is lighter than A12 flywheel, so will not smooth out the power pulses as well. | ||

| - | On the other hand it has less mass, so aids acceleration. You can lighten the A12 flywheel (by machining) or use the already light A10 flywheel (after machining). Unfortunately the A10 flywheel requires machining to use with an A12 (where is machining needed?) | + | On the other hand it has less mass, so aids acceleration. You can lighten the A12 flywheel (by machining) or use the already light A10 flywheel. Unfortunately the A10 flywheel requires machining to use with an A12 (details for machining below) |

| - | + | ||

| - | The smaller clutch pressure plate is held on using M6x1.0 bolts which are prone to snapping. May be worth drilling and retapping to suit M8x1.25 bolts like the rest of the A-series use, but the pressure plate may not have enough clearance/seat area to fit regular M8x1.25, though socket head cap screws may be used as they have small heads. Using M6x1.0 socket head cap screws may be another alternative as they are a stronger material (grade 12.1, vs 8.8 or less for regular bolts) | + | |

| 160 mm clutch area (vs 180mm for all other A-engines) | 160 mm clutch area (vs 180mm for all other A-engines) | ||

| - | <br>{{Album|26653}} | + | <br>{{Album|26653}} {{Album|27233}} |

| * Machine step out of the A10 surface | * Machine step out of the A10 surface | ||

| Line 118: | Line 158: | ||

| See [http://datsun1200.com/modules/newbb/viewtopic.php?post_id=314908#forumpost314908 main forum discussion] | See [http://datsun1200.com/modules/newbb/viewtopic.php?post_id=314908#forumpost314908 main forum discussion] | ||

| + | |||

| + | If using the standard A10 clutch, the smaller clutch pressure plate is held on using M6x1.0 bolts which are prone to snapping. May be worth drilling and retapping to suit the M8x1.25 bolts like the rest of the A-series use, but the pressure plate may not have enough clearance around the head/seat area to fit regular M8x1.25, though socket head cap screws may be used as they have small heads. Using M6x1.0 socket head cap screws in the standard holes may be another alternative as they are a stronger material (grade 12.1, vs 8.8 or less for regular bolts) | ||

| + | |||

| + | [[Datsun B10]] fixing clutch cover | ||

| + | 08120-62010 BOLT M6 x 20 medium carbon steel | ||

| + | 08913-23610 WASHER-lock | ||

| + | |||

| + | {{Album|27234}} | ||

| = FWD = | = FWD = | ||

| Line 127: | Line 175: | ||

| = Part Numbers = | = Part Numbers = | ||

| + | {{Album|26242}} | ||

| + | |||

| + | 20 | ||

| * 12310-18001 ASS'Y-FLYWHEEL B10 | * 12310-18001 ASS'Y-FLYWHEEL B10 | ||

| * 12310-18002 ASS'Y-FLYWHEEL B10 (from E/# A10-87871) | * 12310-18002 ASS'Y-FLYWHEEL B10 (from E/# A10-87871) | ||

| Line 136: | Line 187: | ||

| * 12310-H8910 FLYWHEEL ASS'Y A14S, A15 8011- | * 12310-H8910 FLYWHEEL ASS'Y A14S, A15 8011- | ||

| + | 26 & 27 | ||

| BOLTS - See [[Crankshaft#Flywheel_Bolts|Flywheel Bolts]] | BOLTS - See [[Crankshaft#Flywheel_Bolts|Flywheel Bolts]] | ||

| - | * 12313-10600 DOWEL (3) all A-series A10-A15 | + | 21 |

| * 12312-18000 GEAR-ring, flywheel A10/A12/A14 | * 12312-18000 GEAR-ring, flywheel A10/A12/A14 | ||

| * 12312-18010 GEAR-ring, flywheel A14S 8110- | * 12312-18010 GEAR-ring, flywheel A14S 8110- | ||

| + | 22 | ||

| + | * 12313-10600 DOWEL (3) all A-series A10-A15 | ||

| + | |||

| + | 9 | ||

| BUSHING-pilot: see [[Pilot Bushing]] | BUSHING-pilot: see [[Pilot Bushing]] | ||

| Line 158: | Line 214: | ||

| = VW Conversion = | = VW Conversion = | ||

| - | {{Album|9259}} {{Album|9260}} | + | Fitting an A-series engine to a VW gearbox (dune buggy) |

| + | <br>{{Album|9259}} {{Album|9260}} | ||

| = MT conversion = | = MT conversion = | ||

| - | {{Album|9372}} | + | When adding a flywheel to an engine that was originally fitted to an [[automatic]] transmission: |

| + | * Make sure that the [[Automatic#Flex_Plate|thin spacer]] for the flex plate is off the crank | ||

| + | * make sure that there is a [[Pilot Bushing]] in the crank | ||

| + | * rotate flywheel until all 6 holes line up | ||

| + | {{AlbumH|9372|jpg|327}} {{Album|9419}} | ||

| = Aluminum Flywheel = | = Aluminum Flywheel = | ||

Current revision

Datsun 1200 uses a traditional type of flywheel at the back of the engine. The face matches the Clutch while a ring gear is attached to the perimeter to let the Starting Motor turn the engine. It uses a 271mm (10.7 inch) flywheel with a 105-tooth ring gear.

Also See: * Clutch * Crankshaft

Contents |

Overview

All flywheels for A-series engines interchange — for rear-wheel drive vehicles.

- In 1974 flywheel bolts changed from British Threads to Metric threads. So the bolts are not interchangeable from early to late. See Crankshaft#Flywheel_Bolts for details.

- The A12 flywheel weighs 2.2 lbs (1 kg) less than the A14/15 flywheels

- A12 flywheel is thinner than A14/A15 and thicker than A10 — this affects the clutch functionality. See #Thickness

A10 12310-18001: 8.0 kg (17.6 pounds) A12 12310-H1000: 9.5 kg (20.8 pounds) A12 12310-H2310: 6.4 kg (14.1 pounds) GX, also sold as 'Race Option' A14 12310-H7200: 10.7 kg (22.3 lbs)

A12 FLYWHEEL MEASUREMENTS #Thickness: 28mm ring gear + backing: 20mm back rim to flywheel face depth: 5mm clutch face to inner face depth: 17mm

Thickness

A14/A15 flywheel is thicker than the A10/A12 flywheel. When fitting the thinner flywheel to A14, remove the Engine Plate to compensate.

Mixing/matching flywheels can affect clutch functionality. You may need to use a different size clutch release bearing sleeve, or change the engine plate.

A10: 25 mm thick? * does not fit A12 due to different starter gear angle A12: 28 mm thick (fits A10) ???: 30 mm thick (early A14? machined A14?) A14: 35.6 mm thick (H89 flywheel) A15: 35.6 mm thick (H89 flywheel)

Inspection

If the starter occasionally makes grinding sounds, chances are the flywheel ring gear needs replacing (or just replace the whole flywheel, which is often less expensive).

Yes, you should resurface the flywheel if it is not in good shape!!! Better to not re-grind the flywheel if it doesn't need it.

It is not indicated to turn the flywheel UNLESS cracks appear, or it is not flat (worn unevenly), or the surface is burnt (heavy glazing). Guys will tell you "it is cheap insurance" to machine the flywheel clutch surface regardless, but that's not what the Datsun factory service manual says.

Wash ... in suitable cleaning solution to remove dirt and grease ... Check friction surface of flywheel and pressure plate for scoring or roughness. Slight roughness may be smoothed by using fine emery cloth. If surface is deeply scored or grooved, the part should be replaced.

- 1980 B310 service manual

If it is warped, have it resurfaced. It is it burnt, chattered, or is grooved, resurfacing is called for. But it if still worked great, is flat, and not burnt, don't bother. The Nissan factory service manual does not recommend a resurface unless needed. Every time my Datsun flywheel did not look great, I should have resurfaced it. And everytime it looked great and I didn't resurface it, all was fine.

If the teeth are worn, replace ring gear

Removal and Reinstallation

The crankshaft needs to be locked from turning when removing or tightening the flywheel bolts.

A less effective type of stop can be used in a pinch using a scrap of metal. The bolt will bend while bolting or unbolting the flywheel but no worries, just toss out the bolt when finished

Clean the #Bolt threads -- do not oil the threads -- and use a torque wrench to install.

TORQUE SPECS Flywheel bolts 88 Nm (58-65 ft. lb.)

Installation - torque the bolts in a star pattern (tighten opposite bolts)

When installing the Clutch, use a spline-aligner so the transmission will be able to slide on

Lightening

For race cars, a light flywheel allows the engine to rev faster according to this principle:

The more weight, the more time it takes to accelerate

Now a street car wants a heavier flywheel, so that it will:

- smooth out the combustion pulses

- smooth out the drivetrain

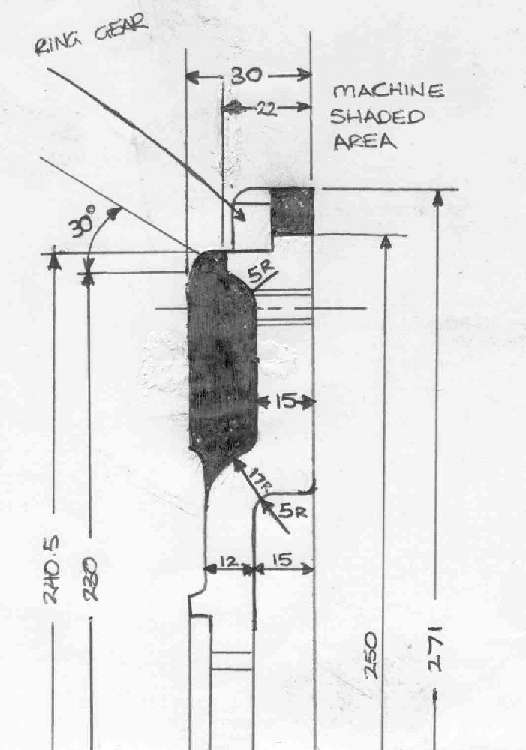

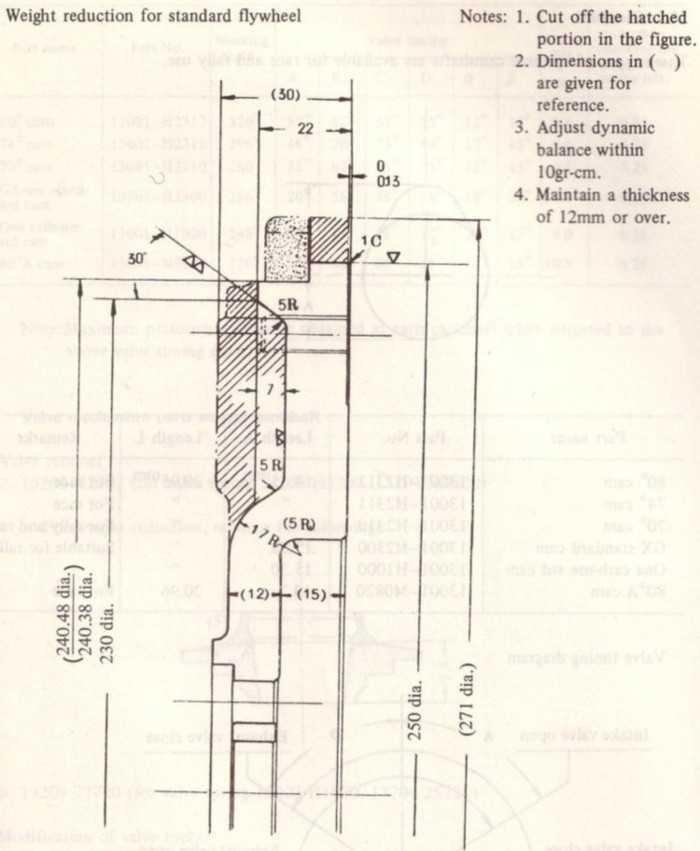

These are the factory specs for flywheel weight reduction:

Finished wheight is about 6.5 kgs --a total of 2 kgs removal

Reference: Datsun B110 Competition Tune-Up Manual, Nissan Motor Co. Ltd., Tokyo Japan 1974

Bolts

Nissan flywheel bolts are very strong. Just clean the threads and use a torque wrench to install.

THREAD TYPE 1966-1973 3/8" x 24 UNF 1973-2002 M10 x 1.25 (from 1973 July)

TORQUE SPECIFICATION 1973 6.5 to 7.5 kg-m (47 to 64 ft-lb)

Best practices:

- Reusing the flywheel bolts is acceptable. Even new bolts will come loose due to shaking. Even #ARP bolts will snap!

- Do not oil the bolts. Just clean them

- Overtightening weakens them. Always use a torque wrench

- Use stock Datsun flywheel bolts. If using aftermarket bolt, ensure they are 1) not too long and bottoming out 2) ensure the head face shoulder design is compatible 3) Use high strength steel like the factory bolts 4) Ensure head size does not interfere with the clutch plate

- Loctite is not needed, even for high RPM use. Per Pitroad☁: "Pitroad tightens ... without applying screw locking agent."

- Make sure the flywheel-to-flange surfaces are clean

- Do not let oil or Loctite get between the two, or the bolts may loosen over time

- Run your finger over the flange. Any burring or uneveness can cause the flywheel to vibrate and come loose over time

- For 7000+ rpm use have the flywheel #doweled

- To reduce vibrations, always re-balance the engine after changing rods or pistons or crank

High Strength Bolts

ARP does not make A-series flywheel bolts (though some use non-A-series ARP bolts on the A-series). In any case the stock bolts are plenty strong.

That being said, Pitroad sells ARP bolts they have selected and verified for the A-series engine.

TORQUE for extra-strength bolts 10.0kg-m to 13.5kg-m

Pitroad☁: "Tightening torque 13.5kg-m Apply screw locking agent without applying oil to the screw part. However, Pitroad tightens with a tightening torque of 10.0 kg-m without applying screw locking agent."

Dowels for High RPM

For 7000+ rpm use, have the flywheel doweled and consider replacing the stock crankshaft pulley with a Harmonic Balancer

Some recommend Using Loctite threadlocker (red) on the bolts, though other racing shops say it is not necessary. If use, apply to the crank threads using a cotton swab instead of putting it on the bolts.

If using high RPM, look at getting the crank flange dowelled. The flywheel is actually clamped on the head of the bolt not on the shank of the bolt (there is side-to-side play), so three dowels 120° apart should do the job. The end of the crank is soft (unlike the crank journals) and easy to drill.

A10 Flywheel

A10 engine flywheel is lighter than A12 flywheel, so will not smooth out the power pulses as well.

On the other hand it has less mass, so aids acceleration. You can lighten the A12 flywheel (by machining) or use the already light A10 flywheel. Unfortunately the A10 flywheel requires machining to use with an A12 (details for machining below)

160 mm clutch area (vs 180mm for all other A-engines)

* Machine step out of the A10 surface * Drill new holes for the larger clutch * Use a longer Release Bearing Sleeve Some say you can shim it

If using the standard A10 clutch, the smaller clutch pressure plate is held on using M6x1.0 bolts which are prone to snapping. May be worth drilling and retapping to suit the M8x1.25 bolts like the rest of the A-series use, but the pressure plate may not have enough clearance around the head/seat area to fit regular M8x1.25, though socket head cap screws may be used as they have small heads. Using M6x1.0 socket head cap screws in the standard holes may be another alternative as they are a stronger material (grade 12.1, vs 8.8 or less for regular bolts)

Datsun B10 fixing clutch cover 08120-62010 BOLT M6 x 20 medium carbon steel 08913-23610 WASHER-lock

FWD

Front-wheel-drive flywheel from E10 Cherry/120A, F10 Cherry/F-II or N10 (310/Pulsar) is smaller diameter and the clutch fits down inside the FWD flywheel.

Interchangeability with Datsun 1200: none

Part Numbers

20 * 12310-18001 ASS'Y-FLYWHEEL B10 * 12310-18002 ASS'Y-FLYWHEEL B10 (from E/# A10-87871) * 12310-H1000 FLYWHEEL ASS'Y A12, A12S, A12A, A13S * 12310-H6200 ASSY-FLYWHEEL A13 * 12310-H7200 FLYWHEEL ASS'Y A14 -7909 * 12310-H7201 FLYWHEEL ASS'Y A14 7910-8010 * 12310-H8900 FLYWHEEL ASS'Y V A14S, A15 8011- * 12310-H8910 FLYWHEEL ASS'Y A14S, A15 8011-

26 & 27 BOLTS - See Flywheel Bolts

21 * 12312-18000 GEAR-ring, flywheel A10/A12/A14 * 12312-18010 GEAR-ring, flywheel A14S 8110-

22 * 12313-10600 DOWEL (3) all A-series A10-A15

9 BUSHING-pilot: see Pilot Bushing

The flywheel "Assembly" includes these parts: * 12312 GEAR-ring, flywheel * 12313 DOWEL-flywheel

ATP ZA543 Flywheel Ring Gear $22.79 * Outer Diameter=10.655" * Inner Diameter 9.451" * Pitch=10/12 Width=.400" * Teeth=105 * Chamfer=FRONT #1231218000

VW Conversion

Fitting an A-series engine to a VW gearbox (dune buggy)

MT conversion

When adding a flywheel to an engine that was originally fitted to an automatic transmission:

- Make sure that the thin spacer for the flex plate is off the crank

- make sure that there is a Pilot Bushing in the crank

- rotate flywheel until all 6 holes line up

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)