<- Back to Turbo (overview and example builds)

There are a lot of choices when turbo-ing your engine. Easiest is to purchase a kit. You can retrofit an OEM turbo engine, or design your own -- it's not too hard but there are a lot of choices.

Overview

Aside from buying a turbo #kit, where to start with turbos?

See Main Forum discussion: POST Setting Up Turbo For Dummies

- Just get a turbo: $100 from junkyard, $300 from eBay or $1100 for top-notch turbo. Just do it!

- connect it to the exhaust

- add your intake: stock carb, SU carb, or EFI -- your choice

- add oil line for oil-cooled turbo

- CONTROL it: limit spark mechanical advance. Limit boost.

- COOL it: bigger radiator is NEEDED, maybe an intercooler (not required)

- drive it

Simplest to connect to stock manifolds -- you'll get 95% of your performance gain by doing it this way. There's a little more power/response/neatness in doing it with custom manifolds, but this way will certainly work.

Suck-though SU connected to Turbo, which is then connected to stock inlet manifold

Or somewhat more complex: a water-to-air intercooled blow-through 32/36!

- Stock inlet with adapter plate for Weber 32/36 Carburetor

- Hat for carb + any mods required (good for 10psi boost)

- Turbo blows into water-to-air intercooler core (eg. RS Turbo, GT4 Celica)

- Core exits into carb hat

Voila, intercooled turbo A-series retaining a short inlet path.

Kit

Turbo kits for the A-series are few and far between. Look for "universal" kits on eBay, or inquire about non-advertised high dollar kits from turbo specialists.

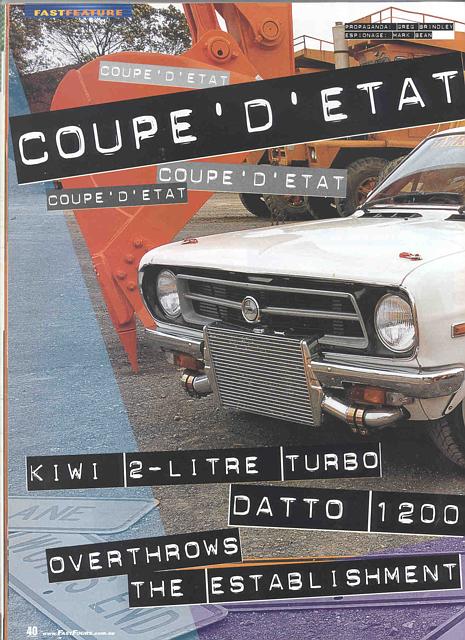

Factory Turbo Systems

Might you spend less money and get more horsepower and reliability by swapping in a factory turbo motor?

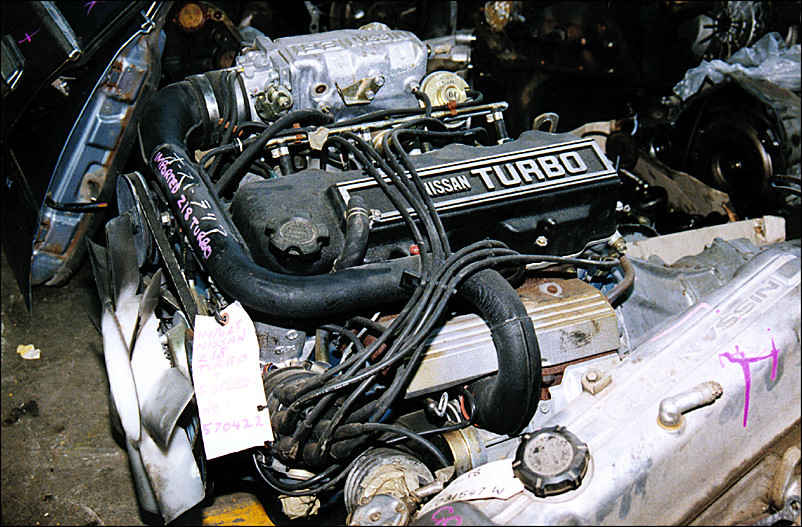

Nissan Turbos

Z18T. See Z-series Engine Swap

CA18DET. See CA-Series Engine Swaps

SR20DET. See SR engine swap

Mazda Wankel Engine – Turbo

Mazda 13BT. See Mazda rotary engine swap

Mazda piston Engine – Turbo

Compression Ratio

For drag racing, you might want to build a special low-compression engine so that all the power comes from the boost. For example 7:1 compression might be targeted by the pro racers, using dished pistons, large CC head and/or a spacer plate or thick copper head gasket. It'll run like a dog at low RPMs and light loads, but like a cannon under full boost. Lower compression = lower power than a stock engine until the boost occurs.

For a street engine, you definitely DO NOT want low compression which lowers your power. Normal compression is best. Limit engine destruction though good tuning practice, mainly with a rich mixture and limited mechanical spark advance. That way you'll have normal power at first, and tons additional on boost. And it will be safe.

Draw-through or blow-through turbo systems?

Section by datto_dave

The carburettor can be mounted in two positions on a turbo-charged engine, and a great deal of controversy exists as to which is better. The carburettor can be mounted such that it feeds air into the turbo then the turbo feeds it to the engine. This is known as a Draw-Through system. Under these conditions the carburettor operates more or less as it would on a naturally aspirated engine. Another school of thought says that the carburettor should be mounted between the turbocharger and the intake manifold. This means that the turbocharger draws fresh air and pumps it into the carburettor, which then feeds the fuel/air mixture to the engine. This blow-through setup allows the use of an intercooler, which draw-through does not. In fact there are several advantages to a blow through over a draw through, because the fuel/air does not have to travel through the turbo. The blow through system requires a boost sensitive rising rate fuel pressure regulator in order to increase fuel pressure with boost pressure as the rpms rise.

Blow-through system feeding Boxed carburetor

Another snag to the blow-through system is that the carburettor must be enclosed in a pressure box and the fuel supplied to the carburettor must be at a suitable pressure above the boost pressure. This means the fuel pressure has to be regulated in accordance with the boost pressure at all times. My own personal preference to date has been for the draw-through system this is largely substantiated by other people in the industry who are running very high-powered turbocharged cars. Almost all are using draw-through systems. However, the speed equipment industry doesn’t stand still. A new development with blow through systems could change the picture. The specially designed for ‘blow-through turbo applications Dellorto side draught carburettors may well be that development.

Blow-through system feeding carb top-hat

A third possibility exists: fuel injection. Here, the injection system has to be designed to measure the amount of air going into the turbocharger by whatever means. It then injects the correct quantity of fuel into the engine at whatever point is convenient. The butterflies for throttling the engine may be situated either prior or after the turbocharger, depending on ease of installation layout. If the injectors are situated in such a position that they injected into a high pressure boosted environment, then the injection pressure must be compensated for by whatever pressure the boost level has reached. Fortunately most fuel injection systems have ample fuel pressure to cope with as high as 40-45 psi used in alcohol burners.

Carburetor Setup

- EFI is best allowing better control of mixture, but carbs can work fine

- Draw through was used by many OEM setups. It is reliable, and the simplest option. The downside is you can't use an intercooler, as the fuel will condense in the cooler.

- Need richer jets to keep air charge cool and prevent detonation

Suck-through means the turbo sucks air from the carb and then into the engine. This also means the carburetor is not directly attached to the intake manifold, but instead the carburetor is connected to the turbo inlet.

Blow-through means than the turbo blows air into the carby. The carburetor is mounted conventionally on an intake manifold.

Carb Size

In a draw-through turbo setup, a given carb will support considerably more power than it would on a non-turbo motor. That said 'the bigger the better' so if you can go a a larger carb then that's definitely preferable as a smaller one may limit the amount of boost you can run without going lean.

For sidedrafts, keep in mind that two of them are normally used in a plenum-less system -- so one will actually deliver the same HP as two when the turbo is used. Additionally the factory A12 twin carbs are 1.5" and were used on L16/L18 engines where they delivered a lot more HP than the A12 makes.

Also See: Carburetor Sizing

A single 1.75 SU POST can make 220bhp in a draw-through system.

Blow Thru

Blow through works well. The main reason to use this over a draw-through is so an intercooler can be used.

See main article: Boxed carburetor

Boxed carb allows a more or less stock carb to be used, the outside pressure balancing the inside pressure

Draw Thru

Suck-through setups are simpler and more fool-proof than blow-through. Yes, you can use downdraft carburetors with draw-through, but the simple tuning nature of a CV carburetor (SU or Stromberg) makes them the favorite. The SU is fully tuned using one spring, one needle, and varying the oil type.

Whilst you can't run an intercooler with a draw-through system, you can run #Water Injection -- and that's enough for you to make some very serious horsepower.

Turbo kit with Stromberg carburetor (Datsun L-series engine)

Cooling

The key to successful turboing is controlling temperatures:

- For the expected HP output, upgrade your radiator to suit

- To avoid engine-damaging detonation, keep the intake air cool via an intercooler

- To avoid engine-damaging detonation, keep the combustion cool via water injection

Intercooler

An Intercooler is not needed, for example the first three years of the Porsche 911 Turbo didn't have one (75-77) and still this 3.0 liter turbo outperformed 7.5 liter NA cars. However there are very good reasons to use an intercooler, including:

- Intercooler is worth the extra cost and complexity, because it significantly reduces the temperature of the compressed air, which increases the boost possible with a given octane fuel

- An alternative is to use water or alcohol injection. Some OEM applications used water injection (ex. 1962 Oldsmobile Jetfire)

An intercooler can result in far more HP, but requires a blow-through system (boxed carburetor) or EFI port injection. This is because for safety you don't want air-fuel mixture going through the cooler, where it will condense out of the airstream and result in fuel puddles in the cooler!

By keeping the air cool and therefore dense, the same boost will make more HP, because more air is entering the engine. Because it's not overheated, more spark advance can be applied for more HP.

Can you re-purpose a car radiator and use it as an intercooler? Using an aluminum radiator should be better than nothing. Unless someone actually tested this, we are all just guessing as to whether it will work or not. Radiators can flow a lot of water, and air is easier to pump ... so air should flow through w/o significant restriction. Putting this in front of the car should allow some cooling effect, although obviously not as a much as a purpose-designed cooler.

Also see: Intercooler Photo Index

Nissan GTiR factory-style intercooler (top mount) | Traditional in-front-of-radiator intercooler

Water Injection

To make the engine survive, you gotta eliminate detonation (pinging). Then your turbo engine will last many years. Using an intercooler is the most trouble-free method.

An alternative to an intercooler is to use an Anti-Detonant Injection -- water injection (usually a water/alcohol mix). Some OEM applications used water injection, for example the 1962 Oldsmobile Jetfire injected water/alcohol mix and had a 10.5:1 compression V8. For more background see Water injection (engine)ᵂ.

Boost Cooler brand uses a 300 psi pump to inject fluid just before the throttle plate.

Into the air filter is quite effective for a suck through turbo. It not only cools the air fuel mixture but also cools the compressor wheel and that helps the ADI atomise also. But there is a problem with this system, water WILL pit the compressor wheel over time and over time wear out the turbo faster.

ADI tank can use a pump to spray liquid into the system (see discussion about eliminating the pump)

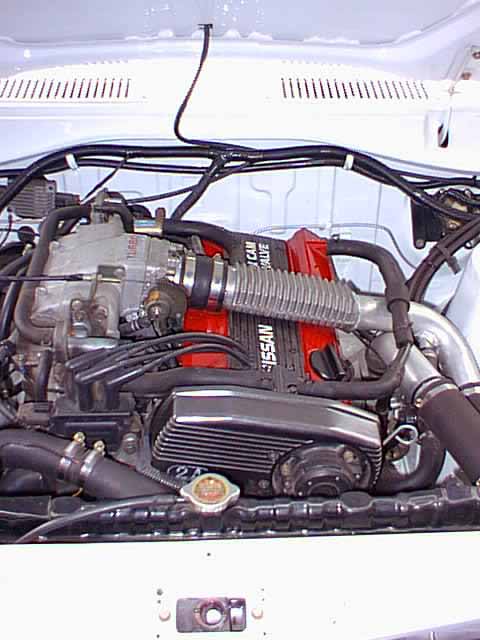

Top Mount or Bottom Mount

Your choice. A top mount turbo screams "look at me!". A bottom-mount turbo lowers the center of weight and looks more "sleeper".

On LHD cars there is less room for a bottom mount (because of the steering gearbox) so a top mount provides additional layout possibilities.

Wastegate

A Wastegate is used for adjustable control over boost pressure. When the set pressure is exceeded, exhaust is routed around the turbine to go out the tailpipe

- Not needed if you carefully size the turbo to the application (ensuring that at maximum rpm, design boost is not exceeded). Older OEM applications used this method.

Blow-off valve (or recirculation valve)

A Blow-off valve is used to preventin the turbo from surging, for example during gear shift or whenever throttle is closed. Porsche uses these, so obviously they work.

- Blow-off intake boost to atmosphere. Boost is lost. Simple, inexpensive

- Blow-off to compressor inlet (recirculate back through turbo inlet). Used to enhance throttle response: Boost is kept in circuit for immediate availability when throttle is opened again

A Blow-off valve is OPTIONAL. Many turbo setups work fine without a blowoff valve.

Ignition

To make a turbo engine last, you must run less total timing -- as the more boost you have, the less timing you can safely (or beneficially) run. And it'd be a good option to look at some type of electronic ignition conversion, to provide the strongest spark possible. You can use points no problem but point are to replaced within months, and the plugs with will require more frequent cleaning and gapping. Use Electronic Ignition for a low-maintenance choice.

Spark Curve

The more compression, the less advance the engine can handle. But a high-compression engine can still use some advance, and even a forced-induction engine needs some advance to make the most power at varying RPMs. The key is LIMITING the advance to a safe level.

Consequences of too much spark advance: cracked pistons, broken ring lands

What about locking the distributor? Yes, if you lock the advance mechanism, yes, it can help prevent detonation, but also it won't make the best power. Locked distributor will only work great at high-RPM, high-boost condition -- which is where racers spend most of their time, so it works well for racing. For a street engine, you will have a more flexible, more powerful engine at all RPMs by NOT locking the distributor, but by limiting the advance.

CONSTANT-LOAD RACING METHOD

- Lock the distributor advance. Set full timing to an appropriate level, say 30 degrees for a high-compression engine or for maximum advance at 16 psi boost: 23 degrees.

LOW-DOLLAR STREET POWER METHOD

- In the distributor, weld the advance slots partially to limit mechanical advance (see Limiting Mechanical Advance)

- Keep the stock vacuum advance (it will have no effect under heavy throttle or boost)

- Connect vacuum advance up directly to manifold. This will help idle and starting out under low throttle, but the vacuum advance will have no effect under heavier throttle

- Set initial timing to lower than normal, say 3 degrees or 0 degrees (instead of the normal 5-7)

- Downside: On a forced-induction engine, the advance won't be right for varying boost levels. You'll have to set the advance for full boost scenario, giving up HP and fuel economy for lower throttle conditions such as highway cruising

BEST METHOD: fully programmable ignition

- use a crank trigger with a fully programmable ignition system. MegaSquirt and other ECUs can provide initial timing, limited full timing, timing under boost and even retard under boost and compensate for high temperatures.

- use a standalone advance controller like the Block Box or an MSD Programmable, which allows for limited mechanical advance along with variable retard under boost, off-boost, and partial-boost conditions. With such a controller, the distributor is locked, and the box takes over the exact timing curve.

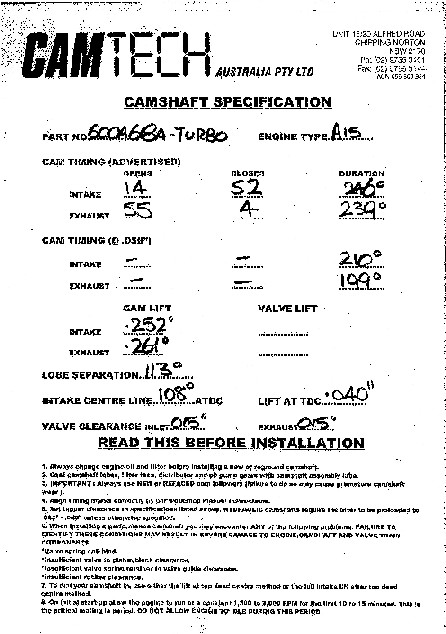

Camshaft

The stock A12 cam works well with a turbo.

If you wish to run lower revs than the standard A12 6,000 RPM shift point, a milder cam can be installed. If you want more power, a higher RPM cam can be fitted.

Your local cam grinder can advise on the best cam for your usage patterns.

Fuel pump

The B110's stock A12 mechanical fuel pump is good for about 96hp, so it can supply a lower-boost turbo system. To make more horsepower, a higher-flowing pump is required. For example A14 pumps flow more than twice the fuel.

- Draw-through

- Stock fuel pump is good for draw-through setup. It's not enough for a blow-through setup, as 2.5psi boost would overpower the fuel 2.5psi fuel pump pressure

- Does not require a return line

- Blow-through

- Using a low-pressure (15 psi) electric pump oughta be good for a 10-12 psi boost.

- Needle and seat has trouble holding more than 10 psi fuel pressure. Better to use a secondary 15-psi pump to cut in only when needed.

- Best setup is to use a rising-rate regulator with a high-psi pump. Excess fuel is returned to the tank via a return line

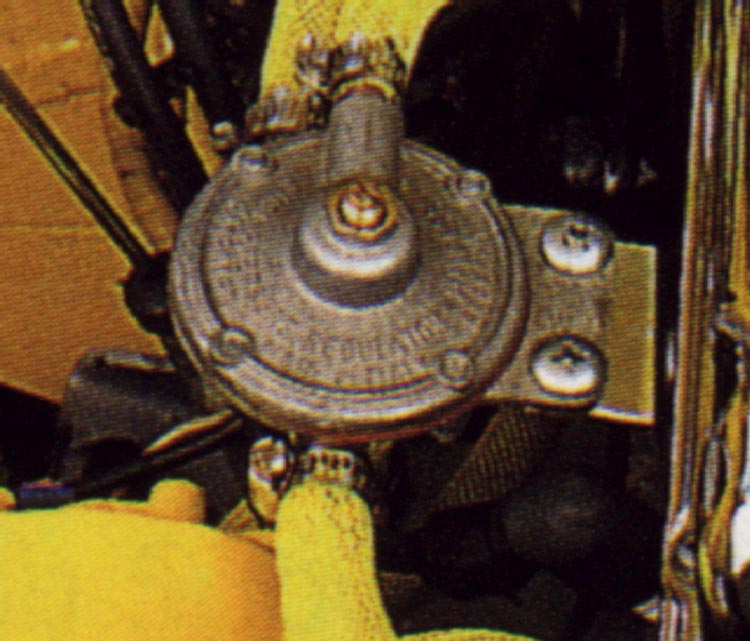

Malpassi rising-rate regulator

Many variable-rate regulators (or fuel pumps with such a regulator) require a return line.

Carter Black fuel pump is meant to be able to go from 4psi to 16psi, while the Carter Silver is for non-boosted engines.

Turbochargers

See main article: Turbos

Block Ventilation

Providing crankcase ventilation is important. Without proper ventilation, normal engine blowby will pressurise the crankcase and can even interfere with the #oil draining away from the turbo.

or

Turbo oil line

Many modern turbos use an oil-cooled bearing. For this reason, when shutting the engine off after a hard run, let the engine idle for 60 seconds before turning it off.

Use appropriate #Crankcase Ventilation, and run a generous sized turbo oil return line to the sump. Without these two things, even a small amount of blowby will pressurize the crankcase and really interfere with the oil draining away from the turbo. If that happens, it can't let new fresh oil in turbo to keep the bearing cool, and the turbo can fail.

Boost pressure

- 6-7 psi is what a lot of non-intercooled OEM applications use

- 15-17 psi is possible with a stock A12/A14

- 14.7 lbs gives theoretically double the airflow so max. power would be about 2x stock, but this isn't actually the result. The reason is that the stock induction and exhaust system won't flow this much air under pressure. However, the low rpm torque could approach 2x (at about 2250 rpm) if a small turbo is used. So a 130hp turbo engine will have much more performance than a 130hp NA engine

- 1986 Honda 1.5 liter ran boost of 4.0 bar - that's 300 bhp ... per cylinder ... with special fuel

POST frankthedolphintrainer: its been proven by a few members already that stock bottom ends can handle massive boost. i still run 15.6 psi on my daily and have had no problems

POST about 240hp A-series: rods ARE stock because he raves about there original quality and strength - he mentioned he was expecting it to throw a rod but it hasnt so he likes the standard rodsBut don't let the engine ping (detonatation):

POST steveo: in a standard bottom end ... [with] a crappy tuning it leaned out up high and pinged like crazy at that amount of boost ... I had trouble with 'rolling' the ring lands above 15psi

Everything about having an engine survive under boost is the "tuning" (control over the fuel burn)

- injection - complete fuel control is easier to achieve than with carburetion. Don't ever let it go lean!

- ignition - complete spark control (limit the advance so there is no detonation/pinging)

- wastegate - no spikes. An external gate may work better

- temperatures:

- Big enough radiator to support the HP made

- keeping air charge cool (to avoid detonation)

- keeping combustion temps cool (to avoid detonation) by rich mixture or by water injection or by lowering the compression ratio

- keeping the turbo bearing cool

- exactly perfect AFR (air/fuel ratio) for complete even burning. Under full boost this means an unusually rich ratio to keep the charge cool and avoid detonation. Note that stoich ratio (14.7) is not ideal for either power nor fuel economy but is used only to enable catalytic conversion

Induction and Exhaust

Obviously, for more airflow, a higher flowing carb, intake, heads (ports and valves) and exhaust system is beneficial. The turbo will increase power on a stock engine, but increasing the airflow capability of the engine will bring your turbo engine to its full potential

Exhaust Manifolds

The stock manifold may be used with a J-pipe for mounting a turbo. But a custom manifold that allows direct mounting is more efficient (allows more power).

Intake Manifolds

The stock inlet manifold may be used. But obviously a larger one makes for more HP.

See main article: Turbo Inlet Manifolds

Troubleshooting

REVVING problem similar to these symptoms?

- revs OK in neutral

- 1st gear revs out to full rpm reasonably smooth

- 2nd gear revs to about 4000 rpm dies for a couple o seconds then revs to about 5500-6000 rpm. 3rd is about the same

- 4th at higher RPMs starts to surge a bit and when you put the foot down a little further and it start jerking

POSSIBLE CAUSE: Fuel pressure too low. See Engine_Trouble_Diagnosis#Engine Won't Fully Rev

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)