Your Datsun 1200 can be converted to fuel injection. Benefits can include smoother, more powerful performance and better fuel economy. Because Injection does not require a restricting venturi like a carburetor, the performance can be better. The highest-performing engines since the early 1940s have been fuel injected -- when the Germans perfected mechanical fuel injection. Top racecars have used injection since at least the early 1960s. Electronic fuel injection (EFI) has made it less expensive as fewer precision parts are needed, and more controllable by electronic circuits.

Mechanical Injection

Mechanical fuel injection has no computer and can also outperform carburetors. It is not as sophisticated as EFI, but can work just as well in drag racing scenarios. Since there is no computer and no electronics needed it is much simpler. However due to the precision required of the parts, it is generally just as expensive as EFI.

Here are some non-electronic systems that could be adapted to a Datsun motor:

- Bosch mechanical (K-Jetronic) from 1970s VWs and Audis (Bosch L-Jetronic was EFI)

<li>Hilborn constant-flow, favored by racers of all kinds

<li>Magoo

</ul>

You'll need the whole package including high-pressure fuel pump, fuel distributor, injectors/throttle bodies and lines.

Electronic Fuel Injection

Why choose electronic fuel injection?

-

<li>Smoother

<li>More fuel efficient

<li>By design more HP than a carb due to no need for a restricting venturi (though some factory EFI still use a venturi)

<li>better fuel distribution, allowing for higher compression ratio and other tolerances

<li>for forced induction applications, automatic a/f control under boost

<li>Better air distribution

<li>automatically compensate for engine tuning changes. With a carb, you'd need to carefully plan out the design, and re-jet every time a component is replaced, for example, if you get a bigger exhaust pipe

With injection, a venturi is not needed. The venturi in a carb is a restriction that somewhat limits ultimate airflow. In the 1950s and 1960s, the fuelie Corvettes had the most power ... still true.And, EFI is easier to work on than an emissions-controlled carb, generally speaking from 1st hand experience. I've rebuilt and jetted many carbs successfully, and tuned EFI systems of various sorts just as successfully. The tools and methods differ, but once you learn both, you'll probably agree with me. On the other hand, I hear the newest cars from the mid-90s up need specialized equipment. I have no experience with these newest systems, but can tell you that the late 80s EFI systems don't require special tools to work on.

Datsun Factory A-series EFI

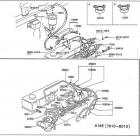

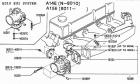

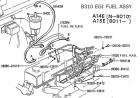

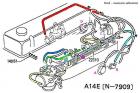

Some 1980-1982 Datsuns in Asia markets came with an OEM (factory) EFI system. Nissan called it "EGI" -- Electronic Gasoline Injection. This is the "rare as" A14E Injection motor.

quote:

a friend of mine has a system that came on the A14 in the M10 Pulsars (very first ones). The set up he got came from Singapore

The A14E engine came in:

- 1979-1981 Langley (N10 Pulsar) -- Asian markets

- 1978-up Feb - Sunny 1400SGX-E Coupe -- Asian markets

"A" series engines are produced in Aichi Machine held in Aichi plant.

Quite a large horsepower difference:- A14E: 92 PS @ 6400 rpm, 11.7 kg-m @ 3600 rpm

- A14: 80 PS @ 6000 rpm, 10.2 kg-m @ 3600 rpm

SSS as I remember at one stage they had import carbie A15 engines for round $600 and injected A14 and A15 for around $800Reportedly, Nepean Sports classics in Castlereagh NSW was selling import motors. carlos' son ran one. These are fairly sought after by the rally guys as the narrow runners provide torque and the length also good top end, too small for a big A15 though.

These possibly came in later model Nissan Vanettes, the reason they seem rare is both my manifolds broke across the bottom of no's 1 & 2 inlet runner. Plus it suffers from reversion with a big cam.

These were also available in asian markets (Japan, Singapore, etc).

quote:

- A14 EGI = HB310 (1978-1980) Type-GX & SGX

- A15 EGI = PB310 (1980-1981) Type-GX & SGX

As for the name in Japan, Nissan calls EGI and Toyota EFI.

Although the EGI system should excel Carburettors in the performance, old EGI is inferior to Carburettors.

Discussions:

As you can see here, the setup is nearly identical to 1980 200SX EFI system:

- This car is missing the air induction piping that goes across the radiator (see 200SX EFI for layout and diagrams)

B310 Factory SetupPerformance

This factory Nissan setup was designed for typical mass-market street performance. It is not a racing system. Expect better low-speed horsepower performance than a stock DCH306 carburetor (due to the longer runners), but the same peak horsepower.

Quote

A factory EFI setup imported from Japan was tried, and found to be much smoother, but ... restrictive above 6000rpm when used with the [racing] cam.Photo Index

Other Choices

If you can find a complete Nissan EGI system for A-series engine, it is the easiest way to convert. It is a relatively straight-forward bolt on. However if you cannot find it, need higher performance, or have a far from stock engine, you'll want to look at other options.

Several choices here:- Swap the entire engine assembly from a another Datsun into your 1200, like a CA18E or E15E

- Adapt an EFI system from another engine to the A-series engine. You can fit 200SX EFI, an OEM Nissan EFI system into other cars.

this set-up will run just about any 4 cylinder in the world ... And it's easier than you think. ;^)Discussion: A15 EFI?? Using E-series setup on A-series engine.

A-series Conversion Kits

Purpose-made kits, including everything needed for an A-series engine, may be offered by some vendors.

You can purchase "universal" 4-cylinder kits that use a carburetor manifold. Prices are about $1200-$3500 -- not including manifold. Kits are available for:- Weber DCOE single sidedraft manifold

- Weber DCOE dual sidedraft manifold

- Weber 32/36 downdraft manifold (use an adapter plate for stock Datsun manifold)

What about spark control?

You can use the stock dizzy, or adapt an E15 distributor into the EFI system.

Weber DCOE Manifold Conversions

Got a Weber DCOE carburetor sidedraft manifold? Design your own system.

Replace the carbs with DCOE-replacement throttle bodies. These are a direct replacement for:

-

<li>Weber DCO/DCOE

<li>Mikuni PHH

<li>Solex ADDHE

<li>SK racing sidedraft

<li>Dellorto DHLA

Available in 40, 42, 45, 48, 50, and 55mm sizes from TWM

These take standard Bosch, Lucas, Rochester (GM) or Weber injectors.

Also available for downdraft IDF-style and IDA-style and DCNF-style manifolds.

suppliers:

- TWM

- speed-technology.com

- www.efihardware.com.au

- Injection Perfection quad throttle body bolts to a Weber manifold. reference: I wanna make injection

Electronic Controller Units

The Electronic Controller Unit (ECU) -- aka ECU/brains/computer -- is critical to operation of the EFI system. You can use the factory stock ECU, or aftermarket ones, including MegaSuirt and General Motors.

See main article: ECU

Fanta injection

Fanta injection can be used with or without fuel injection. Search the main forum for more information. Texans prefer Nehi Grape as an anti-detonant.

Parts needed

-

<li>EFI Manifold, or other manifold sufficiently modified

<li>Throttle body

<li>Injectors and wiring harness

<li>Fuel rail and lines

<li>Gas tank

<li>Fuel pump, high pressure (mounted in tank, or out of tank below level of fuel)

<li>Fuel filter

<li>Fuel pressure regulator

<li>(optional) surge tank

<li>Return line

<li>ECU (Electronic control unit)

Wiring:

-

<li>injector harness

<li>sensor harness

<li>power wiring and fuse

Sensors: one or more of the following:

-

<li>Throttle Position Sensor (TPS)

<li>Coolant temperature

<li>Oil temperature

<li>Intake air sensor

<li>Oxygen sensor

<li>MAP (Manifold absolute pressure -- vacuum sensor. Some can sense boost also)

Injector Sizing

Say the injectors are rated at 3bar (43.5 psi) +-3%. 80% is the normal maximum practical operating capacity. You can get more output by boosting fuel pressure, for example some injectors might be safe at 70lbs pressure.

You need to know the BSFC (Brake Specific Fuel Consumption). For a normally aspirated engine, plan on 0.5 lbs/hour/hp. Put another way, take the HP/2

200 HP / 2 = 100 lbs/hr is the need.

With 4 injectors, they need to be 25 lbs/hr allowing for 80% operation, you should get 30 lbs/hr rated injectors. If you are planning on raising power output later, go up one size to start with.

High or Low Resistance Injectors?

Whether you use High or Low Resistance Injectors depends first on whether your ECS can do both. Get the kind that is compatible.

-

<li>Most OEM controllers use high-resistance injectors (saturated driver)

<li>Many aftermarket controllers use low-resistance injectors (peak and hold)

The low-resistance injectors generally react faster, for more precise control and higher rpm capability.

Used Parts

Yep. Injectors off many cars from the wreckers are perfect for you. Get the injector wiring plug too. For example Ford Mustang 5.0, Chevrolet V8, 4-cyl ECI Magna (the same as VN group A injectors)

Oxygen sensors may be sold very inexpensively by some wreckers. Supply and demand: not too many people buy used O2 sensors, keeping used prices low.

Intake and Exhaust Manifolds

A tuned-runner manifold would not be hard to make one out of some steel tubing and a bit of 10mm plate for the flange, just need a throttle body around 50mm.

quote:

Figure out exactly what you want, take some dimentions and a spare cyl head (if you have one) to an aluminum or stainless steel fabrication place eg, aluminium boat builder, have it fabricated ,then machined and bob's your uncle, you have an injection manifold. I'm an aluminium boat builder by trade, so I couldnt see it costing anymore than $250 - $350 maxInnovative intake manifold allows use of stock exhaust manifold.

You could also use a modified Hilborn injection manifold.

A15 GX manifold with injector bosses welded on

A15 GX manifold with injector bosses welded on

O2 Sensor Reading -- Air/Fuel Meter

O2 (oxygen) sensors can be used to troubleshoot the fuel/air mixture. This uses an Oxygen sensor (Lambda sensor) to display to you how the actual a/f ratio of the engine as it is running. This is good for carbureted cars too, so you can see which way you need to adjust or jet the carb.

Basically, you can tap in to the existing wire for the sensor. You can get a high-impedance ohmmeter at radio shack for under $40, but the specs need to be 20 Mega ohms resistance (most are not this high).

$10 a/f sensor from Autospeed article

full-range LED sensor project from Autospeed article

See datsuns.com tech article. For an excellent description with diagrams, download TWM's PDF file www.twminduction.com for their "Halmeter" product. Link LambdaLink From New Zealand

Camden Industries Zcar Magazine two excellent articles on using Lambda sensor. For more, including build-it yourself A/F meters, see Jason's Weber page

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)