| Revision as of 05:22, 3 December 2009 ddgonzal (Talk | contribs) (->Head Types) <- Previous diff |

Revision as of 05:24, 3 December 2009 ddgonzal (Talk | contribs) (->A12GX Head) Next diff -> |

||

| Line 222: | Line 222: | ||

| === A12GX Head === | === A12GX Head === | ||

| - | The [[A12GX Engine]] uses a cylinder head with dual-valve springs for 6800 rpm operation <br>(compare to stock A12 6400 rpm operation). It used an intake manifold with dual Hitachi HJE38W side-draft carburetors. Compression ration of 10.0 and combustion chamber of 29.1 cm3 with flat-top pistons. | + | The [[A12GX Engine]] uses a cylinder head with dual-valve springs for 6800 rpm operation <br>(compare to stock A12 6400 rpm operation). It used an intake manifold with dual Hitachi HJE38W side-draft carburetors. Compression ratio of 10.0 and combustion chamber of 29.1 cm3 with flat-top pistons. |

| [http://datsun1200.com/modules/myalbum/photo.php?lid=504 http://datsun1200.com/modules/myalbum/photos/thumbs/504.jpg] [http://datsun1200.com/modules/myalbum/photo.php?lid=1002 http://datsun1200.com/modules/myalbum/photos/thumbs/1002.jpg] | [http://datsun1200.com/modules/myalbum/photo.php?lid=504 http://datsun1200.com/modules/myalbum/photos/thumbs/504.jpg] [http://datsun1200.com/modules/myalbum/photo.php?lid=1002 http://datsun1200.com/modules/myalbum/photos/thumbs/1002.jpg] | ||

| Line 237: | Line 237: | ||

| For more details, see Main Article: [[A12GX Engine]] | For more details, see Main Article: [[A12GX Engine]] | ||

| - | |||

| === Early A12T Head === | === Early A12T Head === | ||

Revision as of 05:24, 3 December 2009

Nissan A-series Engine cylinder heads are of one type: inline valves, pushrod valve system (non-overhead cam), two-valves per cylinder. The head is non-crossflow meaning that exhaust and intake ports are on the same side (left side).

Cylinder Head Identification

Most A-engine heads do not have unique casting numbers. For a process of identification see Cylinder Head Identification. This article will discuss various features of cylinder head.

Head Types

A10: Round port, dry manifold, early B10 fittings B10 Coupe: larger chamber size??? A12: Round Port, A10, A12, A12S Van, Early Truck A12: Round Port, Open Chamber USA B110 A12S: new Round Port, dry manifold A12S Van, Late Truck A12S: new Round Port, wet manifold A12S, A13S GX: Extra-large Oval Port, wet manifold A12GX A12T early: Same as GX, but for Cherry A12T late: with new oiling passage A13 (1974): Medium Oval Port, A14-type large valves A14 Round: Round Port, wet manifold, large valve A14S Van A14: Oval Port, dry manifold, A14 A15: Oval Port, wet manifold A14S, A15S, A14T EFI: Medium Oval, wet manifold A14E, A15E H95: swirl port oval (A12A, A14, A15) 1981-1982 USA

"New" means the updated intake manifold bolt pattern (see Bolt Pattern section below).

Distinguishing Features

Any A-type cylinder head will bolt onto any A-type engine. However compression and intake ports are big consideration, as are the manifold bolt patterns. For best results, match port types (e.g. round-port manifold on round-port head). The most critical difference is the rocker shaft oil passage. It is in a different place between early and late engines.

Oil passage in the head

An extra oil passage in the head is needed for some engines. For early engines, make sure your head gasket has the hole! You can punch or drill a corresponding hole in the gasket if needed.

Top: 1974, no passage. Bottom: 1973, has passage.

The old 1967-1973 head has the oil passage:

Boss on outside identifies the head

Compare to newer head: no passage:

The newer engine has the passage in the block instead. The solution for Old engine block, Newer head: drill the passage in the head.

Interchanging

Pre-1974 heads fit on all engines.

1974-up block works with any head.

But for newer head on older block, an oil passage must be drilled:

I took off the head, marked it with the old head gasket, and drilled it on a 45 angle. junior

I have seen a crude system where a 1200 head gasket was placed on the head to determine the position of the oil feed hole in the block. This was centerpunched & a very shallow hole was drilled. [about 1 to 1.5mm] then an angle grinder was used to grind a small trench across the gasket face to provide an oil passage froom this shallow hole to the nearest head bolt hole.Crude as hell, but it worked. A very steady hand would be a prerequisite.

Personally, I would suggest a milling machine if this method is used.

question about oil blockage

Combustion Chamber

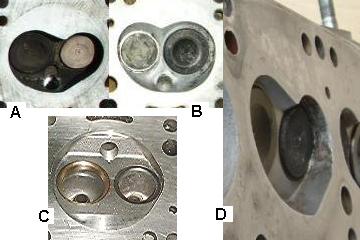

- A,B: Heart-shaped high-compression chamber is good for high-octane gasoline

- a.k.a: closed chamber, peanut-shaped, butterfly-shaped or kidney-shaped

- C: 360 degree open chamber low-compression is good for regular-octane gasoline</li>

- D: Bathtub chamber (from swirl port head)?

Any combustion chamber design can fit on any A-series engine.

Comparo - Closed Chamber vs. Open Chamber

Chamber Size

- A12:

- A12 GX: 29.1 cc (as per FIA papers)

Intake Ports

- Round: These are best for low-RPM operation

- Small oval (28 mm x 30 mm). The 1974 A13 has this design.

- Large oval (28 mm x 34 mm). These std A14/A15 ports are best for high-RPM operation, or for the bigger engines

- GX oval (30 mm x 36 mm). From A12GX and A12T engines.

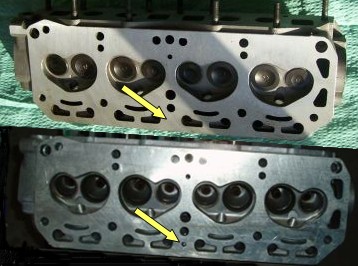

GX Oval vs. A14 Oval Comparo

Top: GX ports go much higher than A14/A15 ovals.

Port Sizes

| Ports | Size (mm) | Exhaust | Raised | Note |

| round | 28 | 27x26 | no | 1971 A12 |

| round | 28 | ? | lowered | 1977 GFU |

| Oval - small | 28x30 | ? | no | 1973 A13 |

| Oval - large | 28x34 | 28x26 | no | Many A14s |

| Oval - GX | 30x35 - 36 | 27x29 or 28x26 | Yes | A12Gx (1971-1973) |

- GX extra-large oval ports (36 mm tall)

Intake Manifolds

All A-series heads will interchange with either type of intake with the following caveats:

- If the intake doesn't have coolant passages, tap the head's coolant ports and install plugs

<li>If the intake does, but the head doesn't, cold-weather starting and

cold-idle may suffer due to insufficient heat. However, warm-engine

operation should be OK.

<li>If the intake does, but the head doesn't, cold-weather starting and

cold-idle may suffer due to insufficient heat. However, warm-engine

operation should be OK.

Intake/Exhaust manifold bolt pattern

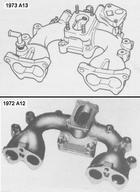

The 1971-1973 A12 differs from the A13/A14/A15 and some A12s after 1973. A12 Wagons and Trucks continue to use the old pattern.

The bolt pattern on the cylinder heads also differ. early A10/A12 heads are only drilled for the older pattern. Newer A12 (1980s/1990s) are drilled for newer pattern. Some newer heads are drilled for both.

Valve Springs

The following A-series heads had dual valve springs. There is a small-diameter spring inside the main spring.

- A12GX

- A12T

- A14T

- A14E

- Heads retro-fitted with dual springs

So dual springs are a good indication of a special head, but not conclusive. You will need to check the intake port sizes and other features to make a final determination.

Valve sizes

| Valves | Intake PN (13201) | In. Size | Exhaust PN (13202) | Ex. Size |

| A10, early A12, late A12 Van | 13201-H1000 | 35mm | 13202-18000 | 29mm |

| A12GX/A12T | 13201-H2300 | 35mm | 13202-H2300 | 29mm |

| Late A12, A13, A12AS | 13201-H2300 | 35mm | 13202-H7400 | 29mm |

| A13(old),A14 & A15 | 13201-H6200 | 37mm | 13202-H6200, H8900 | 30mm |

| A12A, A14, A15 1982 USA | 13201-H9500 | 35mm | 13202-H9500 | 30mm |

| A12A, A14, A15 1982 canada | 13201-H6200 | 37mm | 13202-H6200 | 30mm |

VALVES (A-SERIES)

4 of each required

- 13201-H2300 35MM/1.38" INTAKE VALVE A12, A12GX

- 13201-H6200 37MM/1.46" INTAKE VALVE A14, A15

- 99996-H1100 COMPETITION 37MM/1.46" INTAKE VALVE

- 13202-H2300 29MM/1.14" EXHAUST VALVE A12, A12GX

- 13202-H6200 30MM/1.18" EXHAUST VALVE A14, A15

- 99996-H1110 COMPETITION 30MM/ 1.18" EXHAUST VALVE

Competition Valves are "Polished and tuliped for improved flow characteristics".

Reference: 1984 Nissan Competition Catalog

Coolant Passages

Coolant passages are below the intake ports (present or not). If present, they can be large holes or small holes.

Standard Datsun 1200 heads have no coolant holes on the intake side.

Heads By Engine

Early A Engine

The 1967-1973 heads provide oil to the rocker armshafts in different locations than 1974-up, so when swapping you may need to redrill the oil passage.

A10 head

The 1970 B10 is 9.0:1, same as the B110 ratio. Yet they use the exact same head. This indicates the B10 piston dish is 20% larger.

- Intake valves: 35mm 13201-H1000

- Exhaust valves: 29mm 13202-18000

- (optional) Rally Springs (dual valve springs)

- Round Ports

- Dry manifold

- Early heads have non-A12 fittings

- Late A10 heads are same as A12

A12 Round-port Closed Chamber Head

- All B110 JDM

- H10, head not marked

- USA to May 1971

- Early 1971 model were fitted with Closed Chamber heads. Known in SCCA racing circles as the "H Production" head, legal alternative for A12 engine.

See discussion: Are these A series GX or comp heads? Experts needed!

Some say a ported and polished standard A12 head with larger valves fitted flows about the same as a standard GX head. See head trivia.

A12 Round-port Open Chamber Head

(1971-1/2-1973 Datsun 1200 USA)

- H39, head not marked

- Intake: 35mm

- Exhaust: 29mm

- Compression ratio 9.0:1 with dished pistons

- Open Chamber heads are most common in USA. They were fitted mid-1971 to remove the temperature-spiking "quench" area therefore reducing NOx (nitrogen oxides) emissions.

A12GX Head

The A12GX Engine uses a cylinder head with dual-valve springs for 6800 rpm operation

(compare to stock A12 6400 rpm operation). It used an intake manifold with dual Hitachi HJE38W side-draft carburetors. Compression ratio of 10.0 and combustion chamber of 29.1 cm3 with flat-top pistons.

Dual valve springs, GX cylinder head and intake

- 11041-H2302 A12 GX cylinder head (to 6/73)

- 11041-H5703 GX cylinder head (from 7/73) same specs, but for newer engine style

Nissan Competition called the newer head a "GX" head. But this appears to be the A12T head (11041-H5702).

NOTE: Dual valve springs alone is not an indication of the GX head. N10 A14E engines also used dual-springs, but were not large-port heads. Also over the years many heads have had dual springs added. For ID, check the intake port sizes.

For more details, see Main Article: A12GX Engine

Early A12T Head

- 11041-M0800

Cherry E10 model has a head same or very similar to the A12GX head (11041-H2300).

Late A Engine

1974-up Redesign Engine

A14 Round-port High-Swirl head

These have quench chambers (not open chambers) but instead of being used in high-compression engines, they are designed for high swirl (for better fuel economy and improved emissions). They are used with dished pistons. Unlike the swirl-port heads, these have unobstructed ports. The ports are lowered so that the charge is forced to swirl as it enters the chamber.

A12A/A14 Round-port head

Intake: 37mm

Exhaust: 30mm

Has round intake ports (like the A12 head). Casting numbers are under the valve cover area: "990" towards the rear and "454" towards the front. This is the head used on A12As and some A14s. These cannot be ported out to match the oval port heads (you'll hit a water jacket). These can be found on some late A14s, like 1980. It has two small coolant holes below the intake ports, to provide heat for the intake manifold. These came on the "GFU" and "MPG" cars (USA-market B210 and B310 fuel economy champion models).

A12A Small-Oval Shrouded-port Head

- Intake: 37mm

- Exhaust: 30mm

- peanut-shaped combustion chambers

- Small-oval ports, guide is shrouded

- wet intake

Has an H95 cast into it, under the valve cover area, has what some call a "swirl" port has an obstruction cast into the port to cause the flow to swirl but it reduces total flow. If you look into the port, from the manifold side, you'll see a heavily shrouded port, almost half of the size it would normally be on an A14 head.

If you try to grind out this obstruction, you will hit a water jacket and render the head useless. It too, has the coolant holes in it.

They also have a small but deep combustion chamber, hence a different dish in the piston.

A12 Low-Rise Round Port

- Low-rise Round Port

- G25 cast number

- From late model B122 truck with A12 engine

A14/A15 Oval-port Heads

- Intake: 37mm

- Exhaust: 30mm

There are many part numbers, which differ for year, emission control, accessory fittings, coolant passages, etc.

These heads first appeared with the 1975 A14 engine.

Open Chamber versions can can be milled .080" or more to raise compression.

H72

Sometimes erroneously called the "low compression GX head", it has a casting number "H72". Has a larger 360-degree "open" combustion chamber for lower compression ratios. It does not have the coolant holes below the intake ports. The H72 head was common around 1977-1978. It has the nice straight big oval intake ports. It is better than the A15 oval "swirl port" head, and certainly better for high RPM use than the round intake port A14 heads. EGR port in the exhaust ports.

So is Oval-port "H72" a good head or not? [Naukkis] says the high-compression head is a better design, and not just because of the compression (see New A series oval port head). The quench design of the combustion chamber is more efficient. The best combo for low compression would undoubtedly be a high-compression head used with half-dished pistons (half-flat-top, half dish), but are these available for the A-type engines?

A14 Oval-port High Compression

H89

H75

Competition Head

- Intake: 35mm (optional 37mm)

- Exhaust: 29mm (optional 30mm)

The Competition Head has the large oval ports and a small heart-shaped chamber and was available from Datsun Competition, later called Nissan Competition and then Nismo. The part is unforunately now NLA (No Longer Available). This race cylinder head reported has the same 29 cc chamber volume as the A12GX head.

Sometimes the Competition Head is erroneously called the A14 "GX" head because it has the A14 size valves, but is more accurately described as a ported and polished version of the standard A14 high-compression head.

- 99996-H1167 Competition Cylinder Head (to 6/73)

- 99996-H1165 Competition Cylinder Head (from 6/74)

The Competition heads are "recommended for racing purposes only ... ported, polished ... competition intake (37 mm)... competition exhaust (30 mm)" -- in other words, the same valve sizes as regular A14 heads. However, the valves are tulip-machined for better flow.

Presumably the difference in the two Competition Head part numbers only differ in the oil passage and fittings/bolt holes.

Reference: 1984 Nissan Competition Catalog

Other heads

Anyone have more information on these?

- There is apparently an A14 Oval Port "GX" head which flows more than the A12GX head. reference: GX Head or A15

- An A15 "GX" head was used by Nissan for racing. There are several different chamber shapes and sizes but just the improved flow though the oval ports is better than the stock round ones. The valve sizes should be larger and some were fitted with dual valve springs.

High Roof Heads

Also see: Cylinder Head Modifications Raised-Ports.

Measuring Combustion Chamber Volume

Here's what you need:

- A large syringe marked in CCs (without the needle, or remove the needle).

- a piece of plexiglas, big enough to cover one cylinder. Drill a small hole about 6mm from edge of the plexiglas

- some grease

Syringes are available from animal feed stores or your local chemist. Get a couple of syringes one thats about 20mls and one that has 0.1 increments which is normally about 3mls. That will cost $1-$2.

Here's how to measure:

- place the head upside down as level as possible

- put a small ring of grease around one of the combusion chambers

- place the plexiglas over it and press it flat

- Fill the syringe with water, and measure how many CCs it takes to fill the chamber

This is also a good way to tell if the valves are sealing well. It should hold water for several hours with no visible leak. If the water leaks out, it's time to lap the valves!

Note that pistons came with different dishes according to year, country, etc.

Which Cylinder Head is "Best"?

The two main factors for peak horsepower:

- combustion chamber design: closed chamber "heart-shaped" is more efficient than open chamber

- port flow: oval is better than round for high-rpm use, and larger valves can be useful

NOTE: Don't confuse "open chamber" for a hemi-style chamber. Yes, both are 360-degree 'open', but the term "hemi" refers to valves at 45-degrees to each other (all A-type engines use valves parallel to each other). The "open" chamber is not inherently better flowing, but is used to reduce compression for lower NOx emissions.

Some say to start with the A12GX Engine head due to its high-compression chamber. Adding bigger valves is good for high-rpm power. Others say a ported standard A12 head will flow as much as the A12GX, but this doesn't increase the compression.

GX heads are not always easy to find, though they pop up for sale every year.

"The best head of the easily available variety, IMO is the H89 head from the A15." - A14Force.

Or you could use the H72 head, and shave/mill it to increase compression.

The A14GX (high-compression) head is probably the best all-around head: big valves, big ports and an efficient chamber design. But you probably cannot find this Competition head ... unless you already have one.

Aftermarket piston styles vary (flat-top or dished, and aftermarket popup/domed pistons). With dished pistons, the pistons can be shaved and the block milled (up to 0.090 inch) to make high compression "flat-top pistons".

On the other hand, for a supercharged motor low compression is best, because you can use more boost and gain more power than is lost due to the low compression.

- closed chamber head with a half-dished piston is probably best due to the efficient "quench" combustion

For a low-rpm 'grunt' engine, or for maximum fuel economy, you'll want:

- Small ports<

- large valves with an A14 or A15, small stock-size valves with an A10 or A12 (anyone have another opinion?)

- closed chamber or swirl-port head

So which is better for a street engine?

- High compression engine: pay 15% premium for high-test fuel but get better mpg

- Low compresion engine: buy the inexpensive petrol, but get worse mpg

Modifying a Head

See main article: Cylinder Head Modifications

See: Head Porting (Port and Polish)

Part Numbers

See Cylinder Head Part Numbers

DOHC Heads for A-series

See DOHC Heads

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)