Forced induction comes in two forms: Supercharging and Turbo-supercharging. This article will focus on the turbocharger. For a comparison with the supercharger, see Forced Induction.

Contents |

Overview

Big Power from a stock A-series engines can be had by adding a turbocharger. A turbo setup on an A12 makes more power and torque than a worked non-turbo A14, for a fraction of the build cost.

Turbo setups range from modest to wild.

Safely Turboing

POST frankthedolphintrainer: its been proven by a few members already that stock bottom ends can handle massive boost. i still run 15.6 psi on my daily and have had no problems

POST about 240hp A-series: rods ARE stock because he raves about there original quality and strength - he mentioned he was expecting it to throw a rod but it hasnt so he likes the standard rodsBut don't let the engine ping (detonatation):

POST steveo: in a standard bottom end ... [with] a crappy tuning it leaned out up high and pinged like crazy at that amount of boost ... I had trouble with 'rolling' the ring lands above 15psi

Everything about having an engine survive under boost is the "tuning" (control over the fuel burn)

- injection - complete fuel control is easier to achieve than with carburetion. Don't ever let it go lean!

- ignition - complete spark control (limit the advance so there is no detonation/pinging)

- wastegate - no spikes. An external gate may work better

- temperatures:

- Big enough radiator to support the HP made

- keeping air charge cool (to avoid detonation)

- keeping combustion temps cool (to avoid detonation) by rich mixture or by water injection or by lowering the compression ratio

- keeping the turbo bearing cool

- exactly perfect AFR (air/fuel ratio) for complete even burning. Under full boost this means an unusually rich ratio to keep the charge cool and avoid detonation. Note that stoich ratio (14.7) is not ideal for either power nor fuel economy but is used only to enable catalytic conversion

Stage 1

20% more HP than stock.

A stock A-series engine can take 10 psi. You don't even need an intercoolor, and so you can use draw-through on a stock carburetor. But blow-through is easier.

- Stock engine

- Loop piping from stock exhaust manifold (J-pipe)

- Small Wrecking yard turbo ($100). If sized small enough, no wastgate or blow-off valve is needed

- Tee into the oil pressure line, feed it into turbo. Tap a return line into the oil pan

- Piping from turbo to stock carburetor via a top hat

- Set initial timing at 3 degrees

- In the distributor, weld the advance slots partially to limit mechanical advance

- Keep the stock vacuum advance (it will have no effect under boost)

- Fit larger power valve to carburetor

- Fit secondary main jet two sizes larger

- Stock fuel piping with medium pressure fuel pump (above 10 psi)

Limit boost to 5 psi.

Or go to 10 psi for short bursts on cooler days.

Stage 2

10 psi. 40% more HP.

- stock block and head

- Fit Intercooler (precludes use of draw-through)

- Box the carburetor to go higher than 10 psi

- Rejet primary main two sizes larger. Secondary main 3 sizes larger. Power valve increase.

- Retard timing to 0 degrees. Connect vacuum advance up directly to manifold. This will help idle and starting out under low throttle, but the vacuum advance will have no effect under boost

- Use 75.5-degree thermostat

- High volume/high pressure fuel pump

- anti-surge tank up front

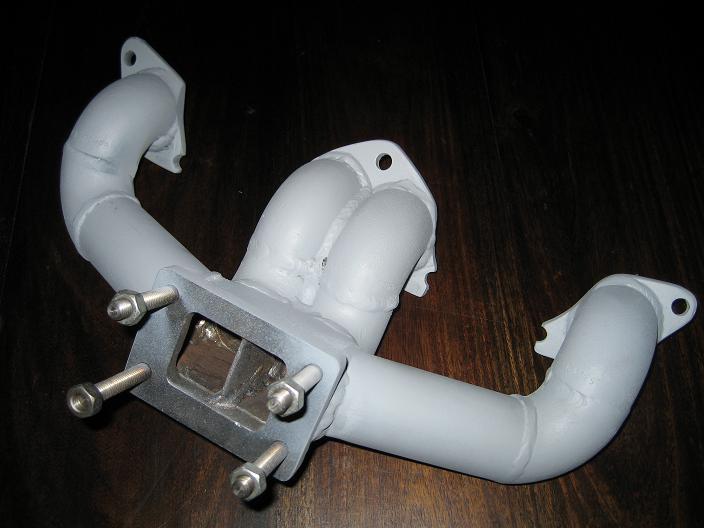

- Use custom exhaust manifold to mount the turbo

- 2" exhaust

- H165 rear axle

Stage 3

100% more HP than stock. Requires modified engine, but not high-RPM usage.

2 bar (28.2 psi)

1 bar (14.7 psi)

Do all the stage 2 modifications plus:

- Use new Nissan rod bolts, torque to spec

- Use ARP head studs

- Fit Intercooler (precludes use of draw-through)

- Custom pistons for low compression (7:1)

- A12GX head, ported

- Copper head gasket

- Oil Cooler

- EFI (or professionally modified & tuned box carburetor)

- custom inlet manifold with large runners

- 2.5" exhaust

- Carefully-sized ball bearing turbo

- 5/16" fuel lines and high volume/high pressure fuel pump

- Fuel tank modified with baffles, or anti-surge tank up front

- Custom-recurved distributor with Electronic Ignition

- Spark retard system

- Water-injection system

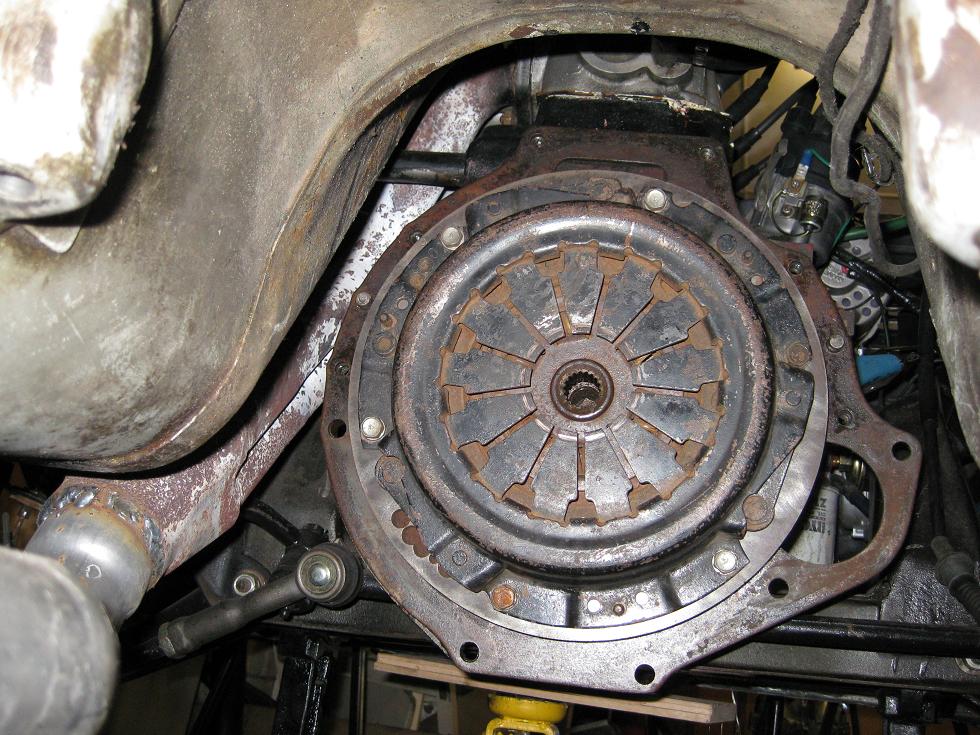

- 63-Series Transmission for A-series

- Heavy duty clutch

- H190 rear axle (or H165 rear axle with heavy-spline axles)

- traction bars

Proof

A15ETT

See main article: A15ETT

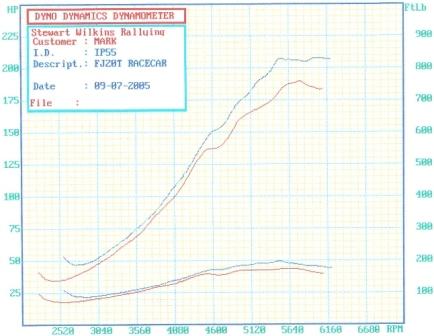

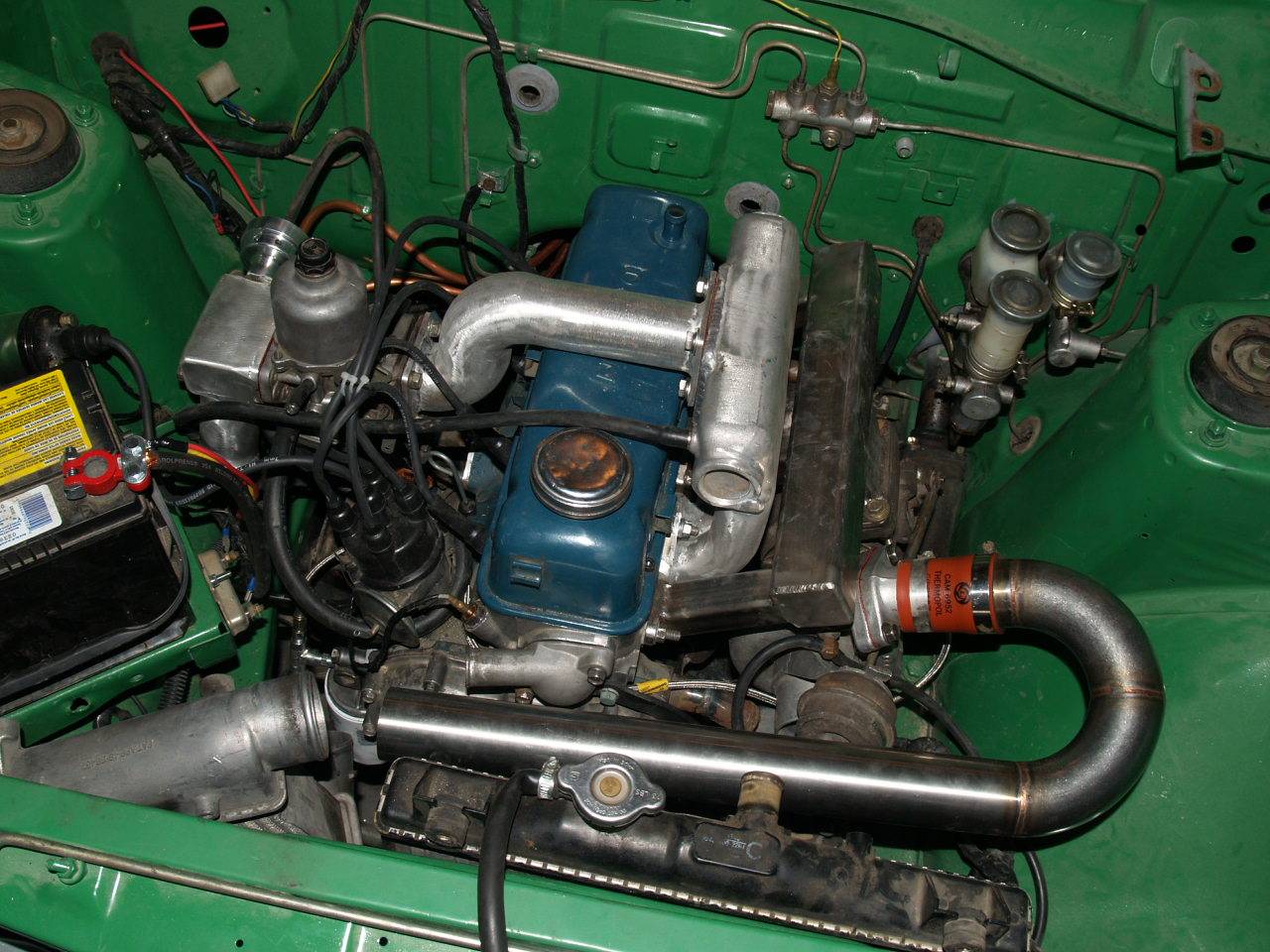

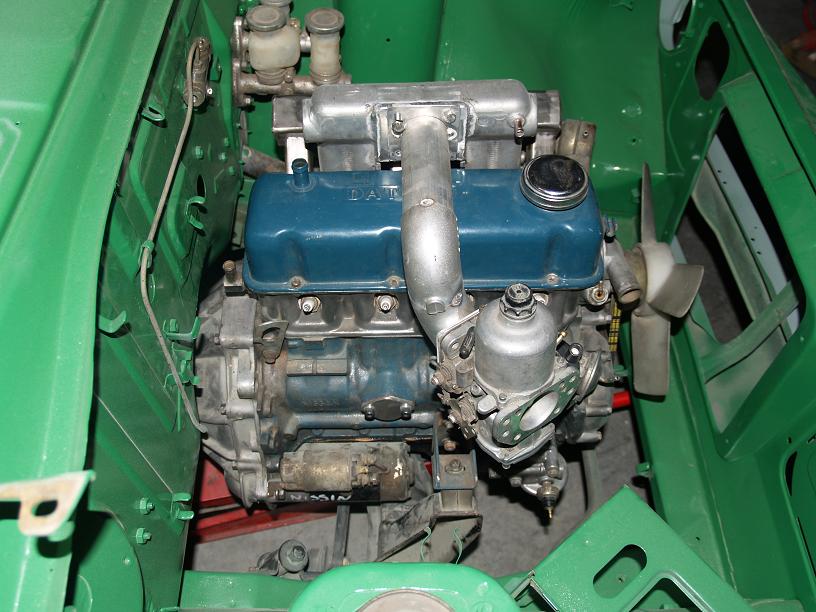

Twin-turbo A15 by 1200rallycar

A15 Before: 52.3 kw (70.1 hp)

A15 After: 75.6 kw (101.4 hp)

Sikyne's A12

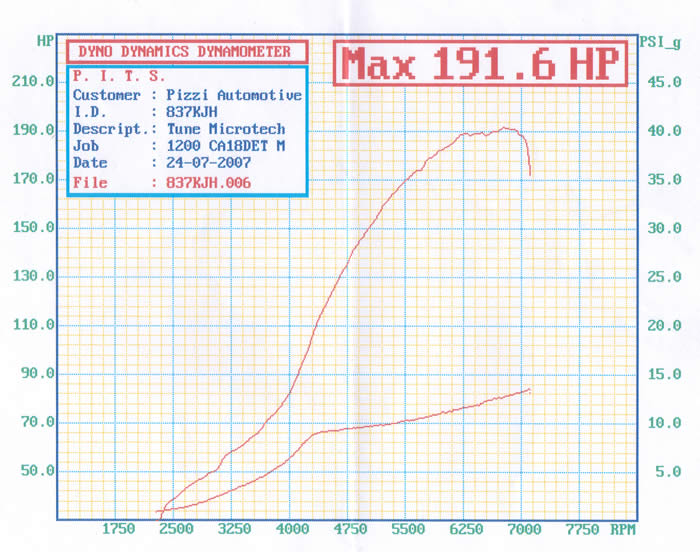

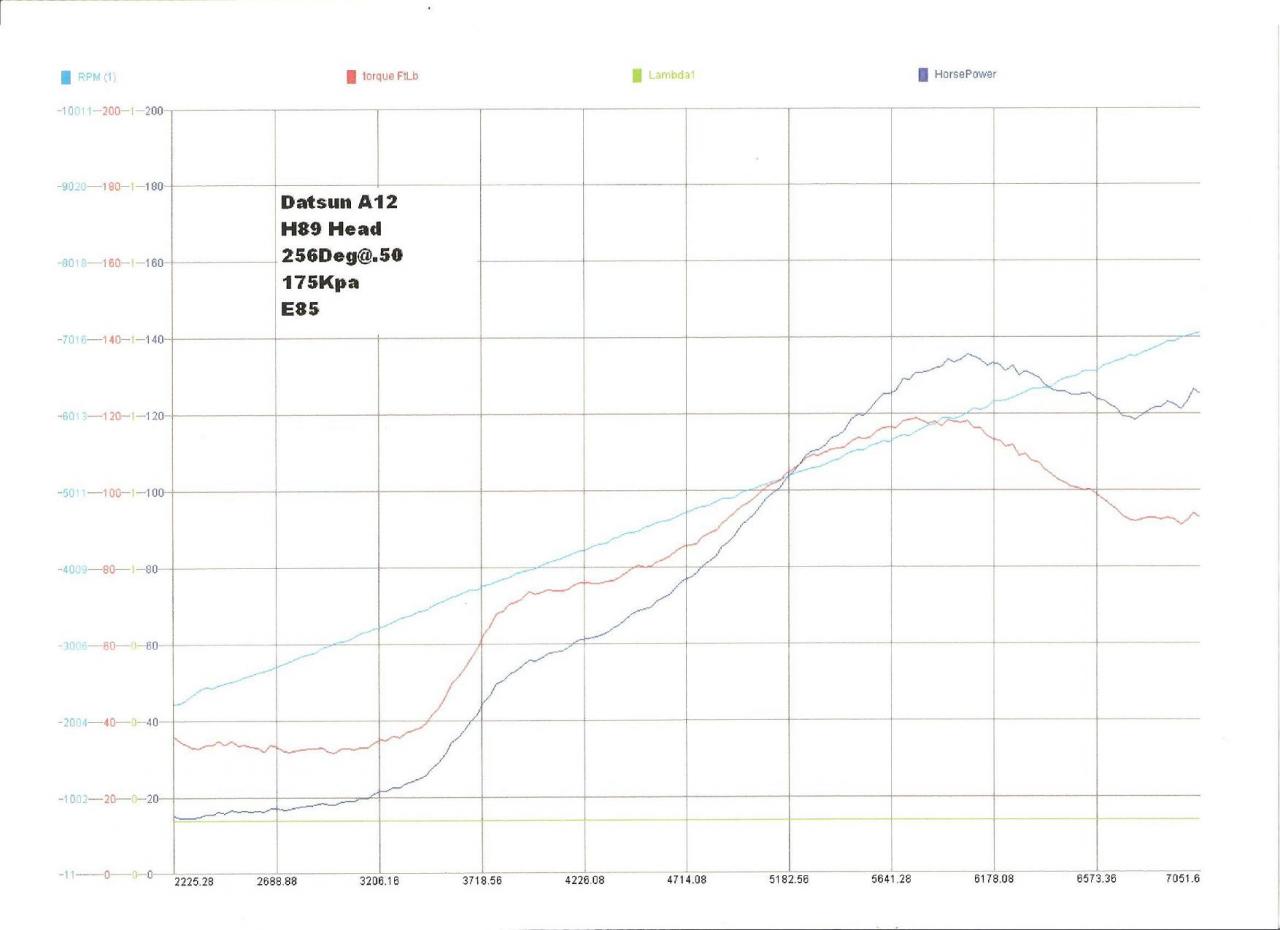

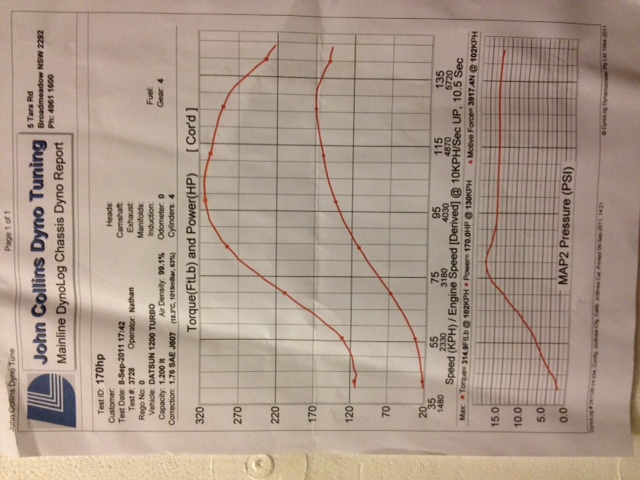

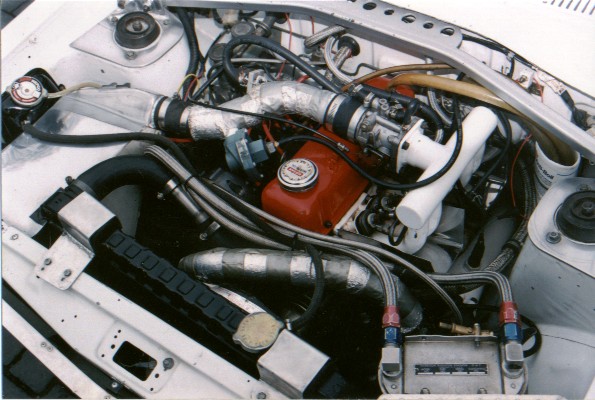

160+ rwhp @ 15 lbs boost (standard H89 Head) 240+ rwhp @ 24 lbs boost (big valve ported head) 2nd-hand GT2860R (707160-5) ball bearing turbo E85 fuel, intercooled stock and unmodified H89 head Cam: 236 Degrees at .050 lift Maximum advance at 16 psi boost: 23 degrees ARP head studs stock pistons, crank and rods standard headgasket about 120 Lb Ft from 5100 to 6800 RPM @ 15 psi

Turbo systems

Oh boy, there are a lot of choices when turbo-ing your engine.

Kits Factory Turbo Systems Draw-through or blow-through turbo systems? Carburetor Setup for Blow Thru and for Draw Thru Cooling: Radiator, Intercooler and Water Injection Top Mount or Bottom Mount Wastegate Blow-off valve (or recirculation valve) Spark Curve Camshaft Fuel pump Boost pressure Exhaust Manifolds and Intake Manifolds Troubleshooting

Builds

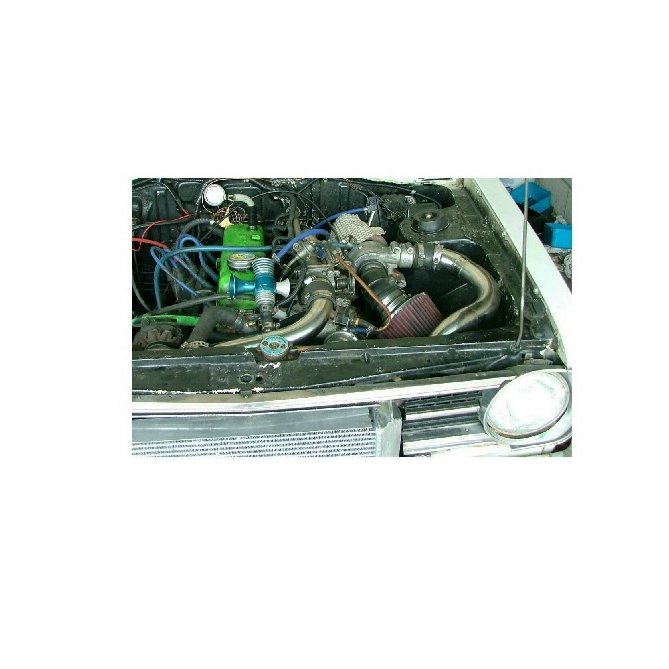

120jas

Top Mount: TD04 draw-through Dellorto

B110SSS

B20 A15

chris1200t

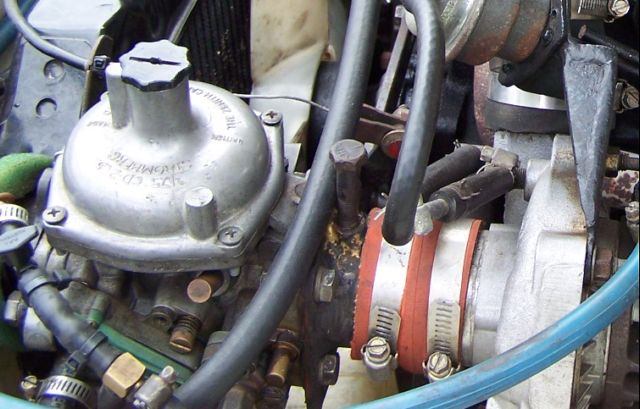

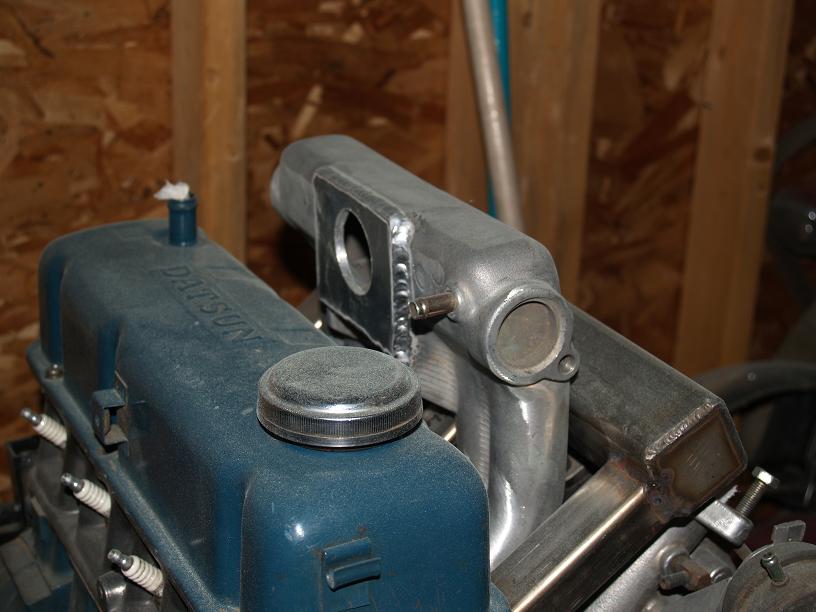

March 2005 A12 engine A12 inlet manifold (plenum removed) Daihatsu 1000cc turbo * bolted to exhaust manifold heater flange suck-through 2" SU carburetor from MG

2nd version: Blowthrough

December 2005 boxed Hitachi carb IHI rhb5 turbo Custom manifold

3rd version

November 2006

naturally aspirated dual Mikuni-Solex

dato8u

POST power: will do 13s now still with the standard block

datsmokin

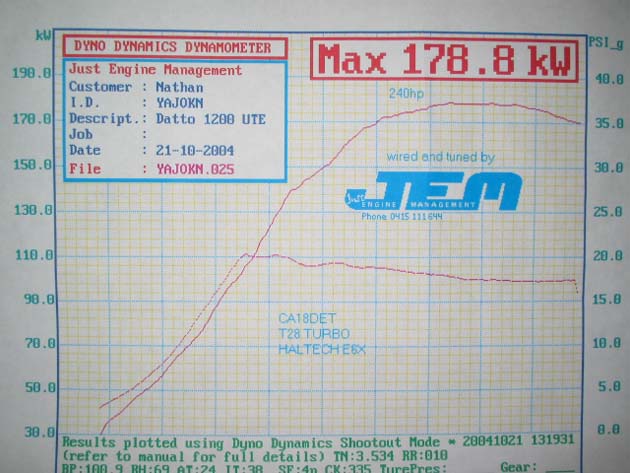

datsonovic

Zenith-Stromberg 1.75 with T04 turbo. See POST 7 years of 30 pounds and all is well

- A15 in Datsun VB10 running 30psi boost

- dyno'd at 105 kw @6000 rpm with 17 psi boost

- running BP Ultimate pump gasoline with water injection

- 90,000+ KM 30PSI AND ALL IS WELL

tourque of the 1500 isnt lost off boost. after 3000 she starts spooling up and by 3500 shes on boost at 4000 shes on full boost and dosnt run out until well after 7000

Datsun100ATurbo

A15 turbo intercooler twin Dellorto 40H homemade adjustable cam timing gear big valves: 42mm + 33mm custom modified piston dish

Empson

fat910

Unmodified A12 short block 8 to 10 pound boost hi flow garrett t2 custom hat and weber carb custom sump vl turbo fuel pump with malpassi fuel reg saab turbo bov

It is easier to build up a 120Y engine instead of a 1200 engine as the alternator is not on the exhaust side

frankthedolphintrainer

Weber 32/36 blow-thru with frankthedolphintrainer turbo manifold

finn

Finn may have the world's quickest A-series engine. It runs a high 11 second quarter mile with Turbo Master Power.

josh_c

Suck-through SU, the classic setup

kegs

Turbocharged A15 Twin Dellorto DHLA 45 carburetors on Redline manifold Custom airbox hat Garret A/R 48 turbo Intercooler from 200SX 2.5 inch dump pipe Liverpool Exhaust

oan78

A12 Sedan with Weber and Hitachi turbo

A12 wagon with 175 Stromberg and Mazda 20B turbo

rezlo

ZA turbo A15, and when racing class rules changed, changed over to A14

rice

For maximum boost, use a large turbo. Lag is heavy, but still operable.

* Drawthrough * 45 Weber DCOE carburetor * T4 turbo @ 10 psi * Compression ratio: 8.2:1

topgear

A12 turbo made 100kw rwhp on 12-13 lbs boost

- stock block except for new rings

- A14 head

- suck-through SU carburetor

- no intercooler

sikyne

slam1024

slam1024 added a turbo

* 1973 Datsun 1200 2-door sedan * Custom manifold with runners from Tercel * stock SU blow-through setup from 1.3 liter MG Metro Turbo

steveo 1

Using stock exhaust manifold with suck-through. Cut oval port manifold with hose to connect it to the pipe work that goes to the commpressor side of the turbo and the turbo sits on the sunny manifold. it look better in real life!

ThomasSymes

$8,000 from Jake's Performance in Canberra originally built for Simon Woolford ex-Canberra Raiders A15 engine built Garrett turbo Weber downdraft modified for blow-through use intercooler Upgraded Radiator fuel system surge tank etc exhaust system All pipe work inc Boost controller runs 7 or 11 psi up to 14psi 130rwkw with papers

Photos

See Turbo Manifold Photos Turbo Photos 1 Turbo Photos 2 Intercooler Photo Index

![[Datsun 1200 encyclopedia]](/wiki/upload/wiki.png)